Process for preparing urushiol formaldehyde condensation polymer/montmorillonite nano composite paint

A urushiol formaldehyde and nano-composite technology is applied in the field of nano-composite coatings and their preparation, which can solve the problems of poor weather resistance and the like, and achieve the effect of improving the anti-ultraviolet ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

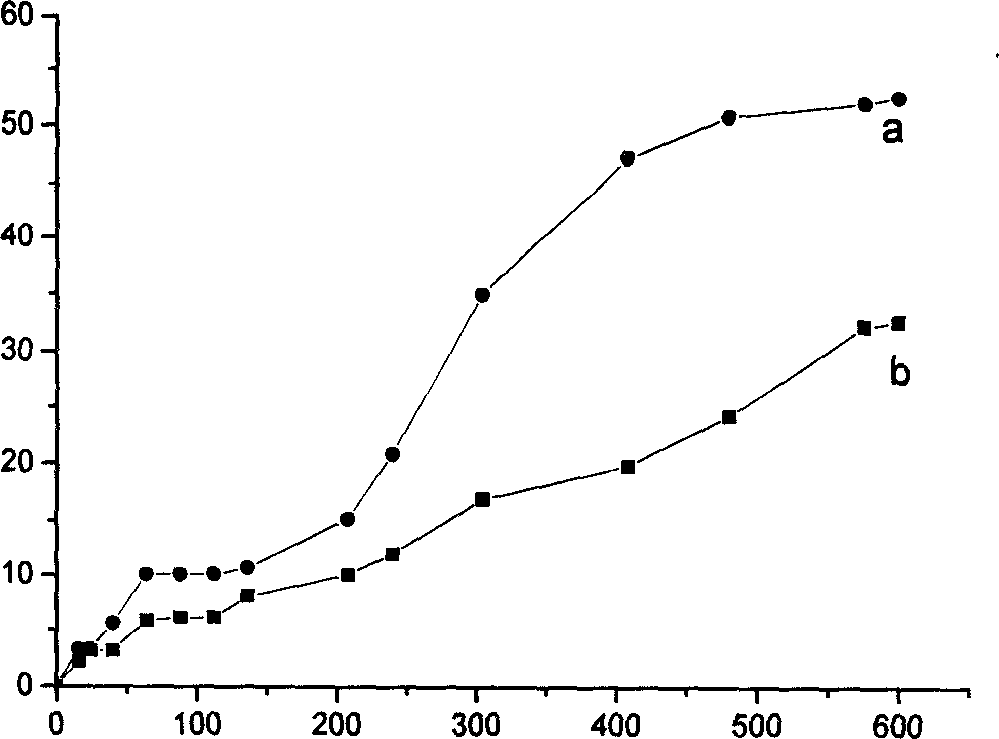

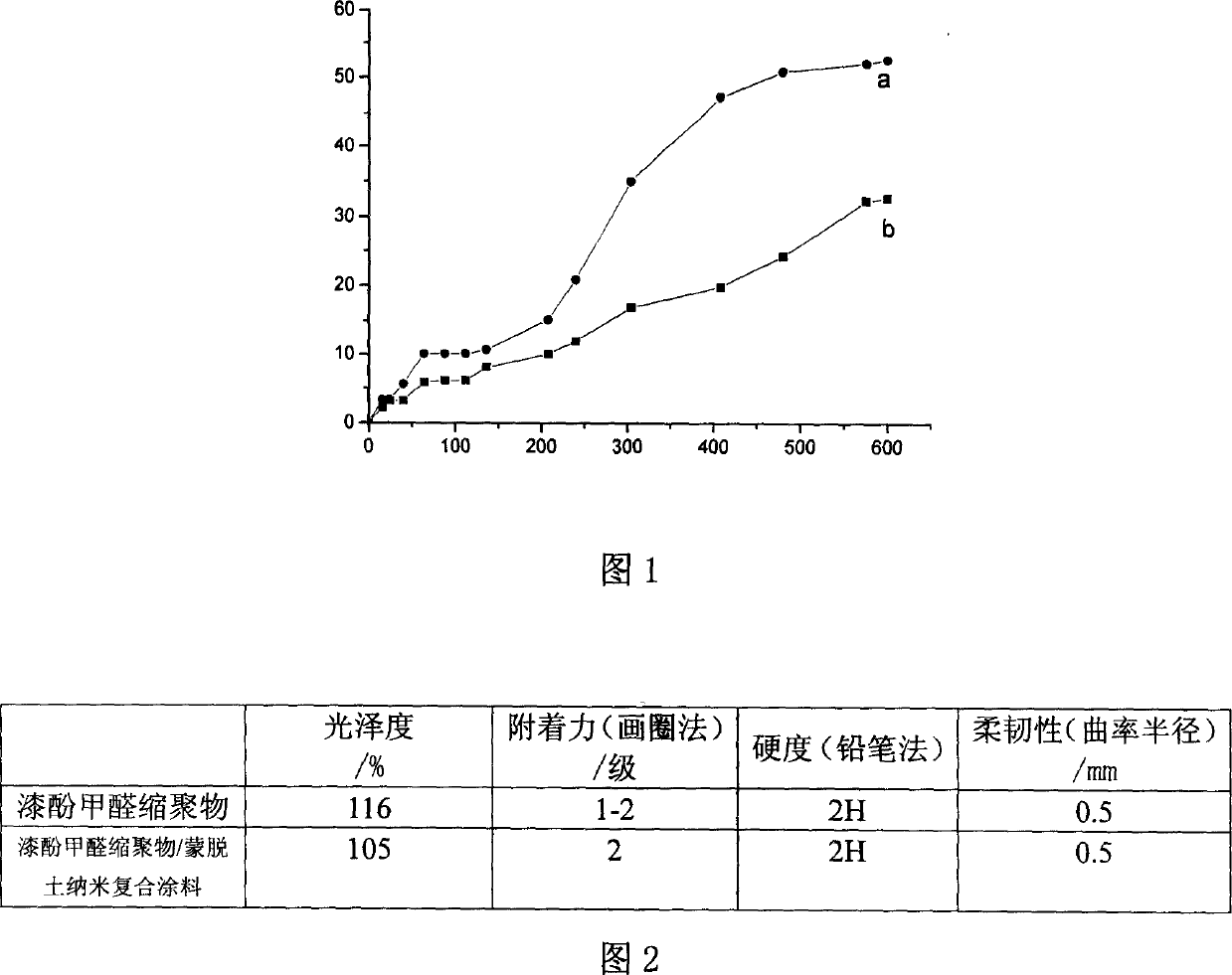

Image

Examples

Embodiment 1

[0012] Add 100 grams of urushiol in a 500 milliliter three-necked flask, 3.0 grams of organic montmorillonite (BP-183) soaked in an appropriate amount of xylene solution for 48 hours, 6.2 grams of hexamethylenetetramine, 150 grams of xylene, and ultrasonically After shaking for 30 minutes, install a thermometer, agitator, water separator and condenser; raise the temperature to 80-90°C for 1 hour, then raise the temperature to 138-140°C and heat to reflux for 2 hours, lower the temperature to 110-118°C, add 55.5 grams of n-butanol and 1.6 grams of phosphoric acid were heated and stirred at 110-118° C. for 1 hour to obtain urushiol-formaldehyde condensation polymer / montmorillonite nanocomposite coating.

Embodiment 2

[0013] Embodiment 2: Add 100 kilograms of urushiol, 6.2 kilograms of hexamethylenetetramine, 150 kilograms of xylenes, 3.0 kilograms of organic compounds that have been immersed in an appropriate amount of xylene solution for 48 hours and ultrasonically vibrated for 30 minutes in a 500-liter reactor. For montmorillonite (BP-183), heat up to 80-90°C for 1 hour, then heat up to 138-140°C and heat to reflux for 1.5 hours, lower the temperature to 110-118°C, add 55.5 kg of n-butanol and 1.6 kg of phosphoric acid, continue Heating and stirring at 110-118° C. for 1 hour, and cooling to prepare the urushiol-formaldehyde polycondensate / montmorillonite nanocomposite coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com