High-temp. organic metal chemical vapor deposition device with connected multi-reaction chamerbers

A chemical vapor deposition, organic metal technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of cross-contamination, great differences, difficult to meet the requirements of different materials growth, etc Increase the heating temperature and expand the effect of using functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

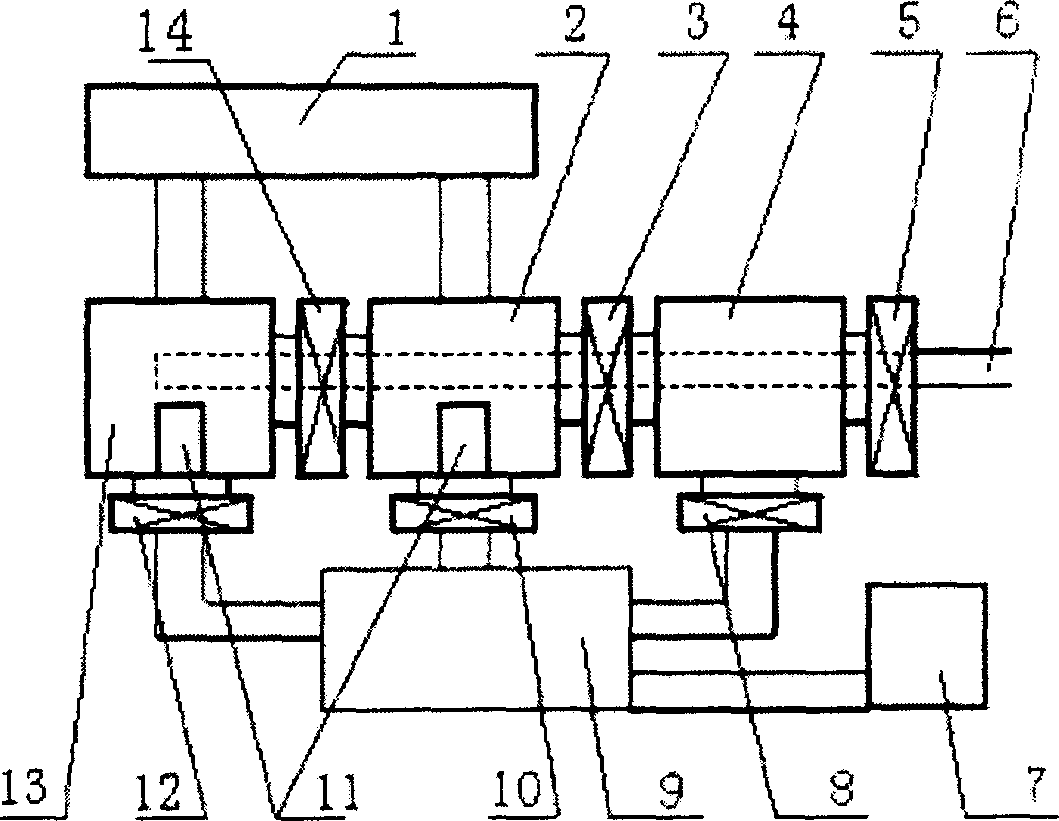

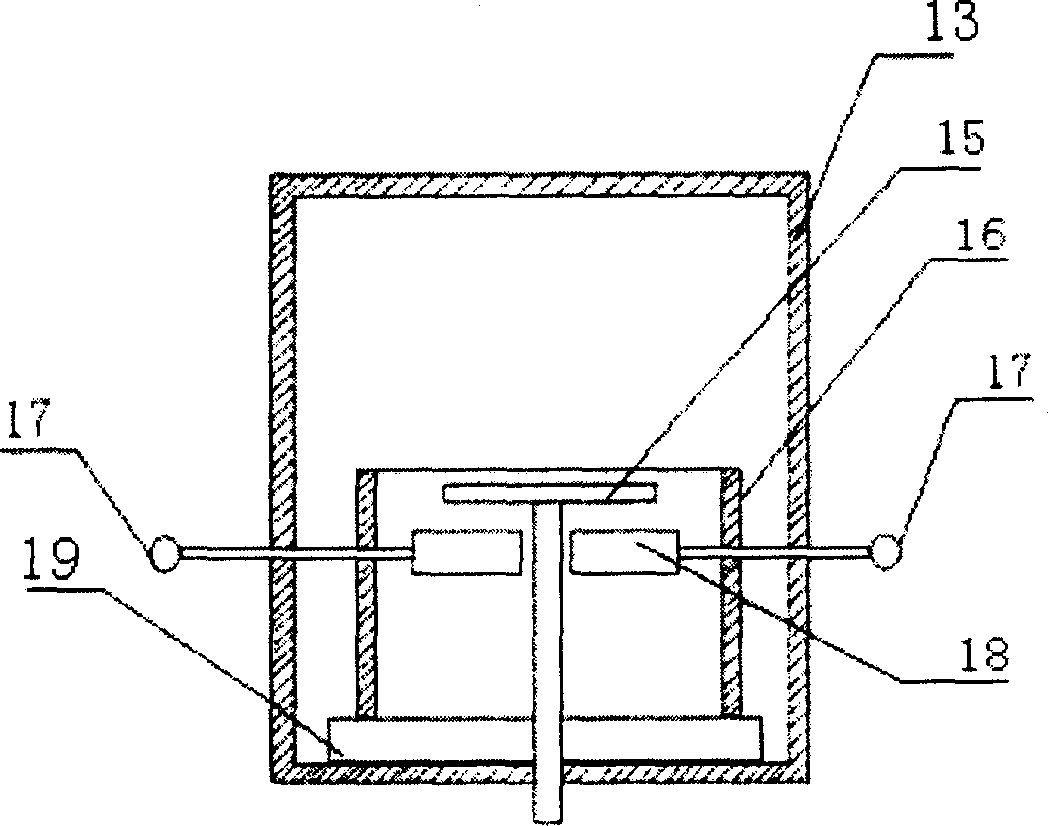

[0016] figure 1 Among them, 1 is the gas circuit system, 2 is the first reaction chamber, 4 is the sample presetting chamber, 6 is the sample delivery mechanism, 7 is the tail gas treatment and alarm system, and 9 is the vacuum unit. These six parts are in the existing MOCVD device. permanent establishment. They are connected as a whole by the transport pipeline and controlled by valves 3, 5, 8 and 10 respectively. 13 is the second reaction chamber that the present invention increases, and this reaction chamber is communicated with the first reaction chamber and gas circuit system 1, vacuum unit 9 by pipeline, is controlled opening and closing by valve 14 between two reaction chambers, and valve 12 controls the first reaction chamber. The connection between the second reaction chamber and the vacuum unit. A sample heating mechanism 11 is respectively provided in the first reaction chamber and the second reaction chamber.

[0017] In this embodiment, the two reaction chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com