Coating formulations for limited play data storage media

A formula and coating technology, which is applied in the field of storage media with limited playback, can solve the problems of losing intellectual property rights and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation of the data storage medium is first to make the base material in a common reaction equipment suitable for mixing various masterbatches, such as single or twin-screw extruders, kneaders, and blenders. The extruder should be kept at a temperature high enough to melt the base material masterbatch without causing it to decompose. For polycarbonate, for example, temperatures from about 220°C to about 360°C, preferably from about 260°C to about 320°C, may be employed. Likewise, residence time in the extruder should be controlled to minimize decomposition. Residence times of about 2 minutes or longer may be employed, preferably not longer than about 1.5 minutes, particularly preferably not longer than 1 minute. The mixture may optionally be filtered, such as through a sieve pack, to remove contaminants or decomposition products prior to extrusion (usually into pellets, sheets, webs, etc.).

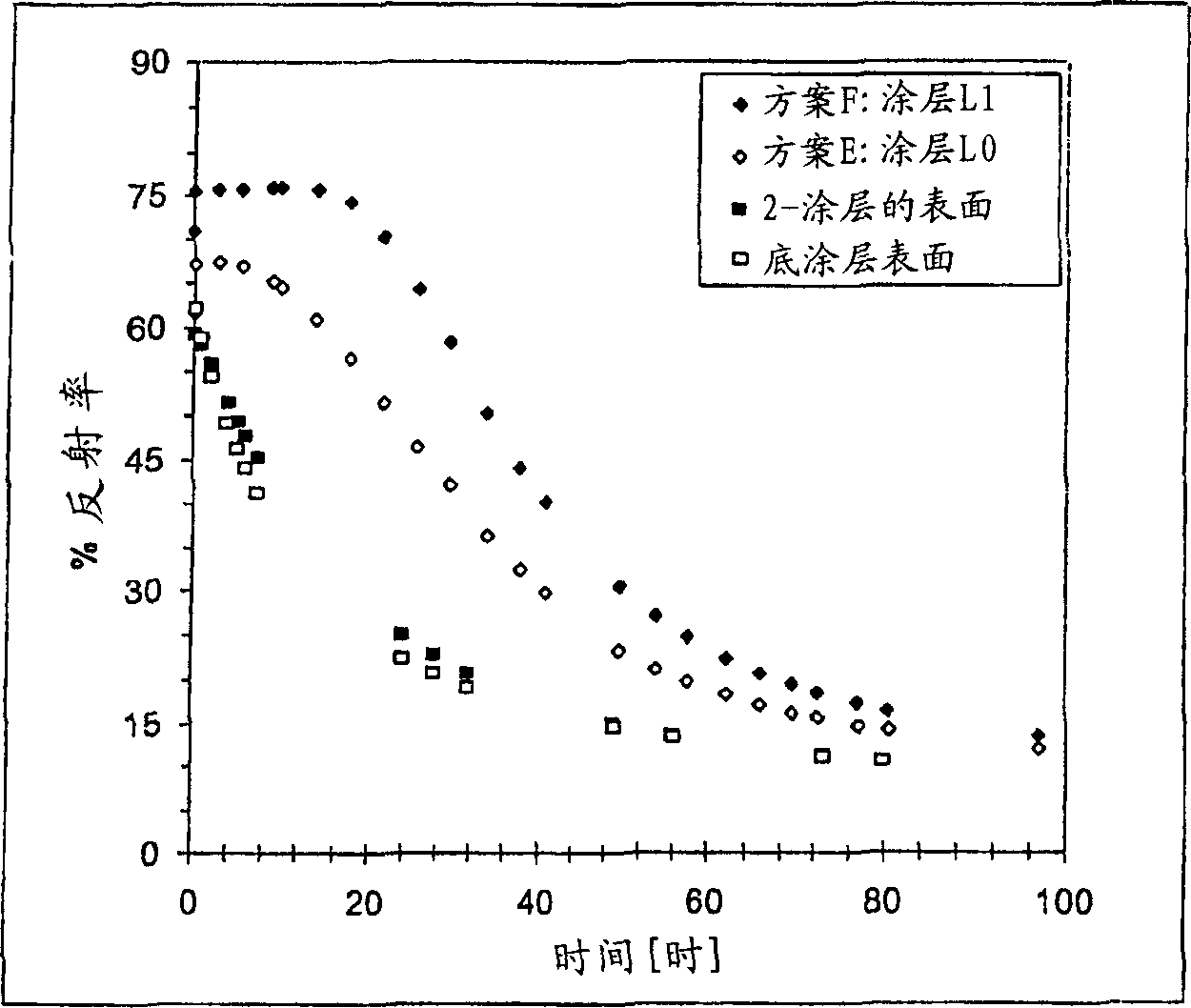

[0040] After the plastic composition is formed, the substrate can be...

Embodiment 1

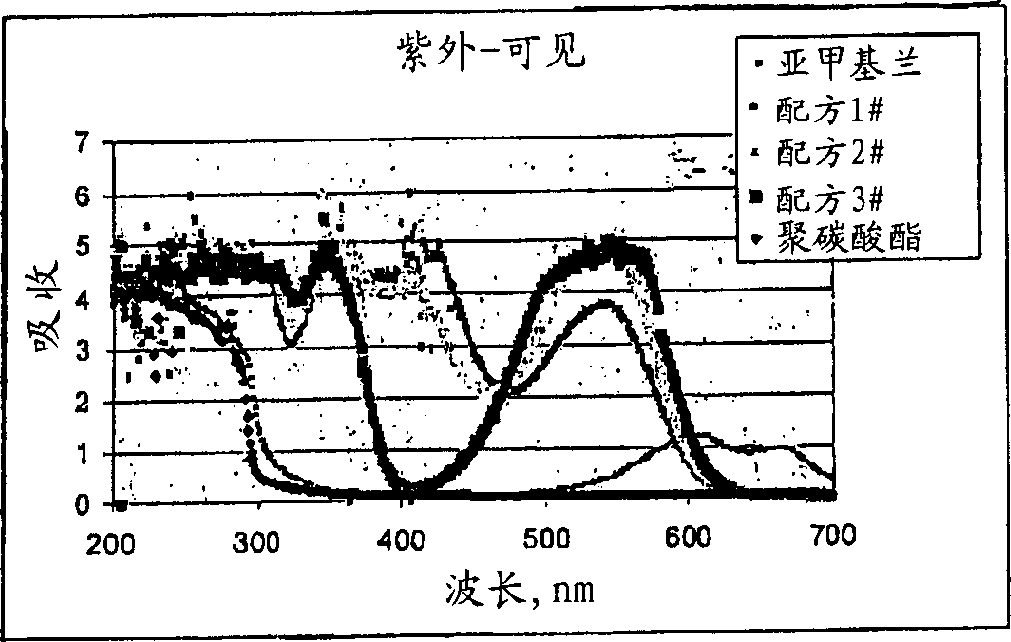

[0157] This example describes the preparation of a polymethyl toluacrylate / oxidized leuco methylene blue coating solution.

[0158] To 450 g / -methoxy-2-propanol in the bottle was added 111 g of Ineos Acrylics Elvaci in 2008 polymethyl methacrylate (inherent viscosity 0.183 cm 3 / g), and rolled on a roller machine to dissolve it. The solution was transferred to a flask, and an ammonia flow of about 100 ml / min was introduced to the surface of the solution, and heated to about 80°C. The deaerated solution was cannulated under nitrogen pressure into a degassed bottle closed with a rubber stopper.

[0159] To prepare a colorless methylene blue solution, 4.85 g of methylene blue trihydrate, 2.05 g of camphorsulfonic acid and 148.3 g of 1-methylamino-2-propanol were mixed together in a 250 ml flask with a rubber stopper. The stirred mixture was heated in a water bath at 90°C while a nitrogen stream was passed through the inlet and outlet at a rate of about 100 cc / min with a syringe...

Embodiment 2

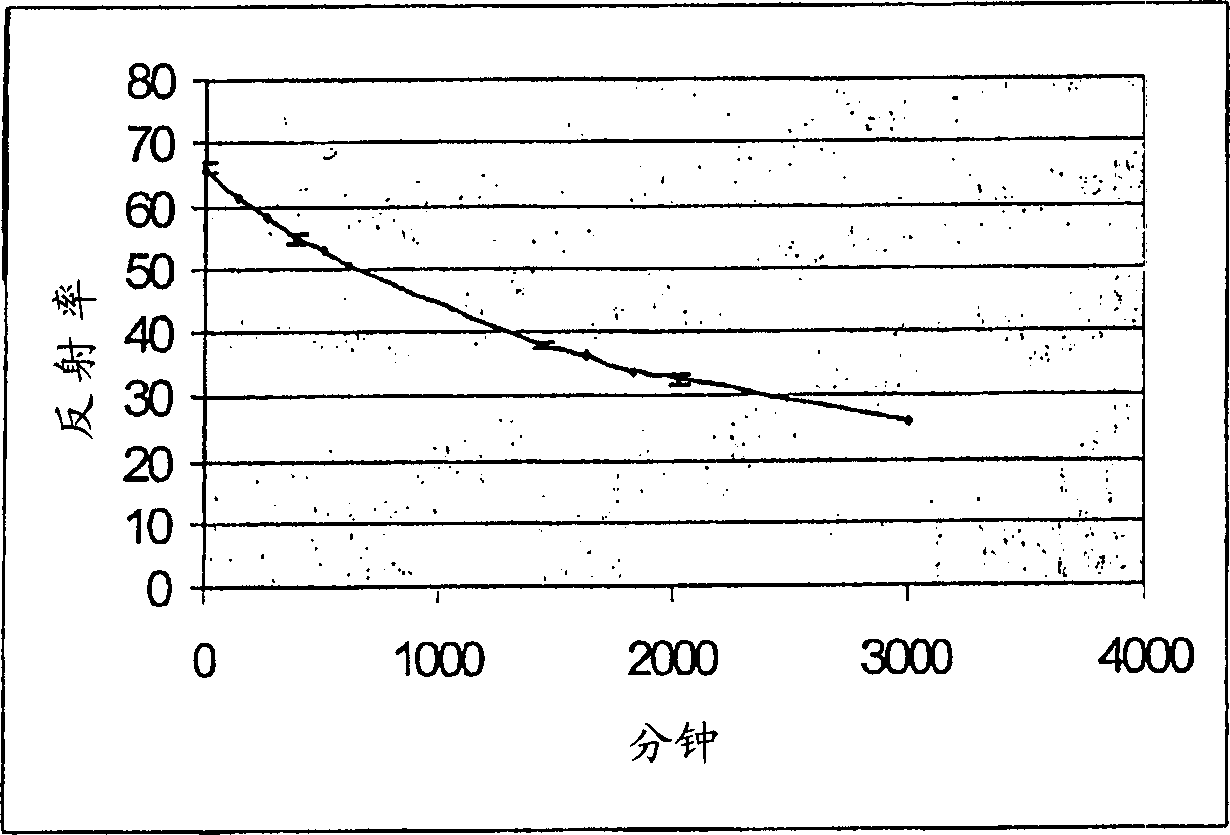

[0162] This example illustrates an optical disc prepared by coating with poly(methyl methacrylate) / oxidized leuco methylene blue. About 3 mL of the polymethylmethacrylate / oxidized leuco methylene blue coating solution of Example 1 was applied to the DVD in a spin coater in a ring around its inner diameter. Spin coating at 600 rpm for 60 seconds, the coating was tack free and very blue.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com