Monocline type gadolinium aluminate based fluorescent powder and method for making same

A gadolinium aluminate-based, phosphor technology is applied in chemical instruments and methods, luminescent materials, etc., to achieve the effects of high color purity, high luminous intensity, and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

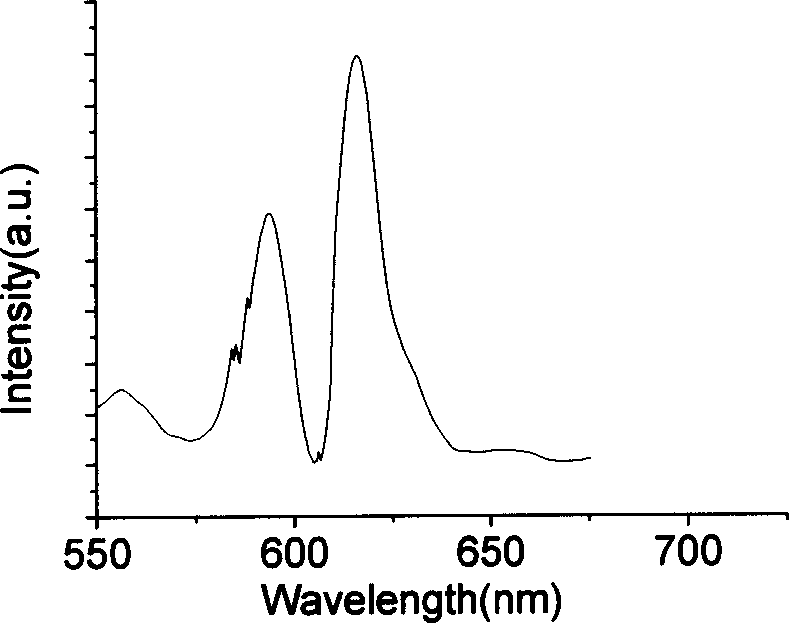

[0016] Take 7.5g aluminum nitrate (Al(NO 3 ) 3 9H 2 O), 7.327g gadolinium oxide (Gd 2 o 3 ), 0.1408g europium oxide (Eu 2 o 3 ), 25.05g citric acid, and a sufficient amount of concentrated nitric acid were dissolved in deionized water, stirred to form a uniform solution and adjusted to a pH value of 7. The beaker containing the solution was placed on a magnetic stirrer, heated to 70°C and kept stirring, and a sol was formed after several hours. Continue stirring and heating until a clear gel forms. Put the gel into a box furnace and heat it to 400 °C to form a gray-black precursor powder. The precursor powder is then calcined at 950°C for 1.5 hours to obtain Gd 4 Al 2 o 9 :Eu(5%molGd) pale pink final product. figure 1 for Gd 4 Al 2 o 9 :Eu 3+ Fluorescence spectra of nanopowders excited by ultraviolet light, indicating that the luminescent ion Eu 3+ It enters the GAM lattice in the form of solid solution, and emits red fluorescence under the excitation of ultrav...

Embodiment 2

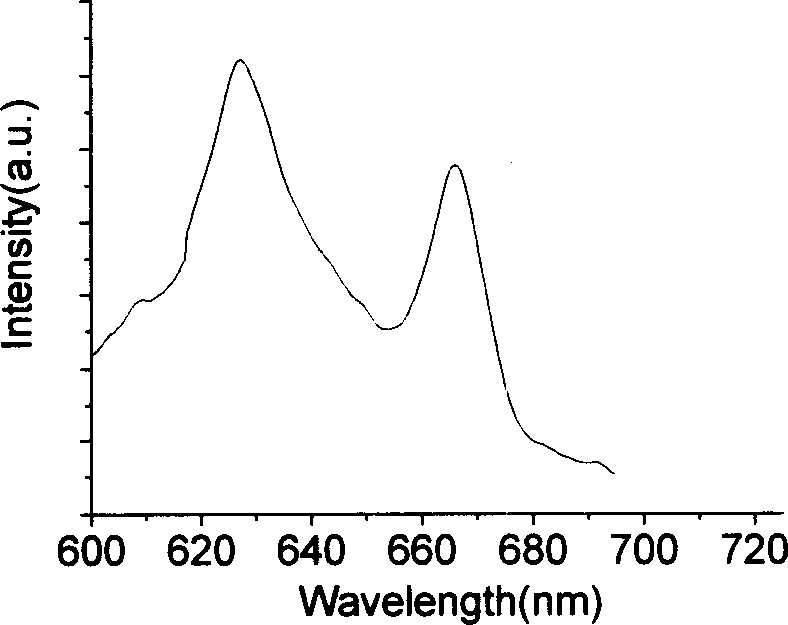

[0018] Take 7.5g aluminum nitrate (Al(NO 3 ) 3 9H 2 O), 7.327g gadolinium oxide (Gd 2 o 3 ), 0.1355g praseodymium oxide (Pr 6 o 11 ), 27g citric acid, and a sufficient amount of concentrated nitric acid were dissolved in deionized water, stirred to form a uniform solution and adjusted to a pH of 3. The beaker containing the solution was placed on a magnetic stirrer, heated to 75°C and kept stirring, and a sol was formed after several hours. Continue stirring to form a transparent gel. Put the gel into a box furnace and heat it to 450°C to form a gray-black precursor powder, which is calcined at 1300°C for 2 hours to finally obtain Gd 4 Al 2 o 9 :Pr(5%molGd) pale pink final product. figure 2 for Gd 4 Al 2 o 9 :Pr 3+ The fluorescence spectrum of the nanopowder under ultraviolet light excitation shows that the luminescent ion Pr enters the GAM lattice in the form of solid solution, and emits red fluorescence under the excitation of ultraviolet light (254nm).

Embodiment 3

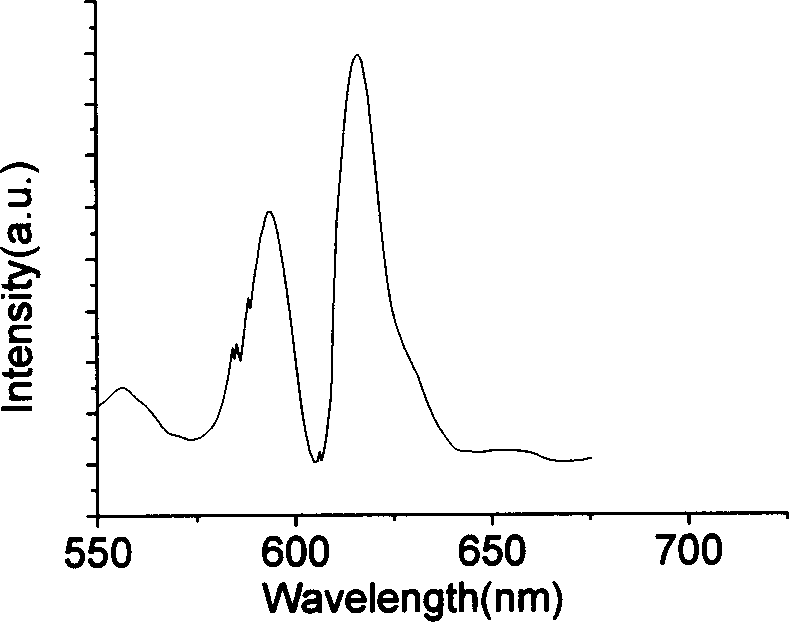

[0020] Take 7.5g aluminum nitrate (Al(NO 3 ) 3 9H 2 O), 7.327g gadolinium oxide (Gd 2 o 3 ), 0.1408g europium oxide (Eu 2 o 3 ), 0.0137g cerium oxide (CeO 2 ), 13g citric acid, and a sufficient amount of concentrated nitric acid were dissolved in deionized water, stirred to form a uniform solution and adjusted to a pH of 5. The beaker containing the solution was placed on a magnetic stirrer, heated to 80°C and kept stirring, and a sol was formed after several hours. Continue stirring to form a transparent gel. Put the gel into a box furnace and heat it to 450°C to form a gray-black precursor powder, which is calcined at 1200°C for 1.5 hours to finally obtain Gd 3 Al 5 o 12 :Eu, Ce light pink final product. image 3 for Gd 4 Al 2 o 9 : Fluorescence spectra of Eu, Ce nanopowders excited by ultraviolet light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com