Apparatus for testing heat protection property of thermal protection clothes or fabric

A testing device and thermal protection technology, applied in the field of thermal protection performance testing devices, can solve the problems of not being able to truly simulate the actual use situation, only considering the plane one-dimensionality of heat transfer, and unable to measure the thermal insulation and radiation protection performance, etc. Stable and reliable performance, light weight, and the effect of reducing measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

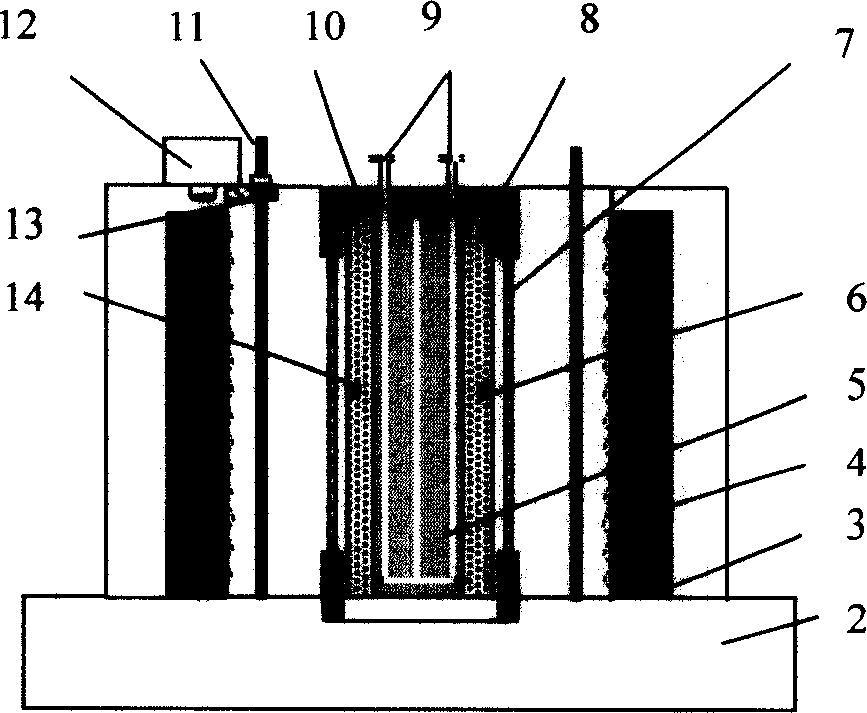

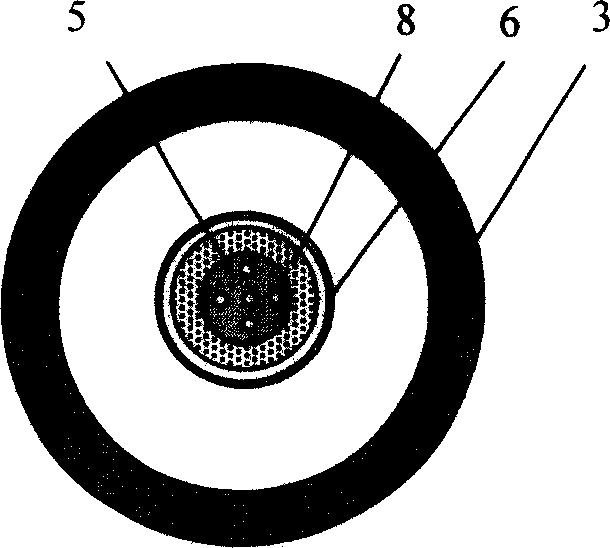

[0018] refer to Figure 1-3 , a heat protection performance testing device for heat protection clothing or fabrics, comprising a test head 1, a constant temperature water tank 15, an analysis control system 16 based on NI virtual instrument technology, the test head 1 is fixed on the frame 2, and fixed On its corresponding groove, the outermost layer of the test head is the thermal insulation layer 3, and the inner adjacent layer of the thermal insulation layer 3 is a cylindrical heat source 4, and the heat source 4 is a mica linear heating jacket with a height of 12cm , The mica heating mantle is an electric heater that winds the resistance heating wire on the mica sheet. It uses the good insulation performance and high temperature resistance of the mica sheet. cylindrical heating element. The size of sample 7 and skin simulator 8 is 12cm, the distance between the heating surface of sample 7 and the inner surface of heat source 4 is 2.5cm, sample 7 is closely attached to ski...

Embodiment 2

[0020] The heating source is a mica linear heating jacket with a height of 12 cm. The height of the sample and the skin simulator is the same as in Example 1. The sample is in close contact with the heat source and the surface of the skin simulator, that is, the air gap between them is zero, and the surface temperature of the heat source is 125°C, it can simulate and test the heat insulation performance of protective clothing when it is in contact with a heat source.

Embodiment 3

[0022] The heating source is a mica linear heating jacket with a height of 12 cm. The height of the sample and the skin simulator is the same as in Example 1. The distance between the heated surface of the sample and the inner surface of the heat source is 2.5 cm. The thickness of the air layer between the skin simulator and the fabric is 6mm, it can simulate the local high temperature heating environment, such as before heating the boiler, to measure the heat insulation performance of protective clothing (gloves, helmets).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com