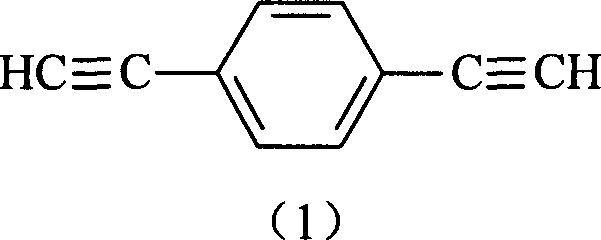

Preparation of high-purity 1,4-diacetylene benzene

A technology of diethynylbenzene and divinylbenzene, which is applied in the field of high purity 1, can solve the problems of complex high vacuum rectification equipment and undisclosed high purity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Bromination of divinylbenzene

[0020] In 200ml of carbon tetrachloride, add 80g of industrial-grade mixed divinylbenzene (produced by Shandong Dongda Chemical Industry (Group) Company, which contains 1,3-divinylbenzene 54.7%, 1,4-divinylbenzene 25.2%) %, ethylvinylbenzene 18%, diethylethylbenzene and ethylbenzene 2.1%), under the condition of avoiding light, slowly add 164g liquid bromine dropwise while stirring, continue stirring for 1.5 hours after the dropwise addition is completed, at this time A large amount of white precipitate was formed, and TLC showed that the reaction was complete. After filtration, the filter cake was washed with carbon tetrachloride, and after drying, 48 g of white solid (1,4-bis-α, β-dibromoethylbenzene) was obtained. Merge the filtrate and the washing liquid to distill off the organic solvent, then distill under reduced pressure to remove the material with a boiling point lower than 160 ℃ / 2mmHg, to obtain 134g viscous liquid (1.3-bis-...

Embodiment 2

[0024] In 200ml of methanol, slowly add 58g (1.07mol) of sodium methylate under stirring, add 48g of 1,4-bis-alpha, beta-dibromoethylbenzene obtained by step (1) in Example 1 after dissolving completely, and heat Refluxed for 2 hours, a large amount of white solid was formed, TLC showed that the reaction was complete, filtered, the filter cake was washed with methanol, and dried to obtain a white solid, which was sodium bromide. Combine the washing liquid and the filtrate, distill off the methanol, distill the residue with water steam, pass hot water at 80°C in the condenser tube, and obtain the azeotrope of 1,4-diethynylbenzene and water, which will become a liquid-solid two-phase after cooling, filter, The filter cake is 1,4-diethynylbenzene; the filtrate is extracted with ether, and the ether in the extract is distilled off to obtain 1,4-diethynylbenzene. Carbon chloride was recrystallized to obtain 9.48 g of white flaky crystals with a yield of 71% and a purity of 99% (GC)...

Embodiment 3

[0026] Preparation of 1,3 / 1,4-diethynylbenzene mixture

[0027] In 300ml of methanol, under stirring, slowly add 167.5g (2.99mol) potassium hydroxide, after completely dissolving, add 134g of 1,3-bis-alpha, beta-dibromoethyl obtained by step (1) in Example 1 The mixture of benzene and 1,4-bis-α,β-dibromoethylbenzene was heated and refluxed for 2 hours. At this time, a large amount of white solids were formed. TLC analysis showed that the reaction was complete, filtered, and the filter cake was washed with methanol to obtain white Solid, this is potassium bromide. Combine the washing liquid and the filtrate, distill to recover methanol, distill the residue with water steam, and pass hot water at 80°C in the condenser tube to obtain an emulsion of a mixture of 1,3-diethynylbenzene and 1,4-diethynylbenzene and water. Extracted with ether, distilled off the ether in the extract, and distilled the residue under reduced pressure, collected fractions at 65-80°C / 2mmHg to obtain 27.01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com