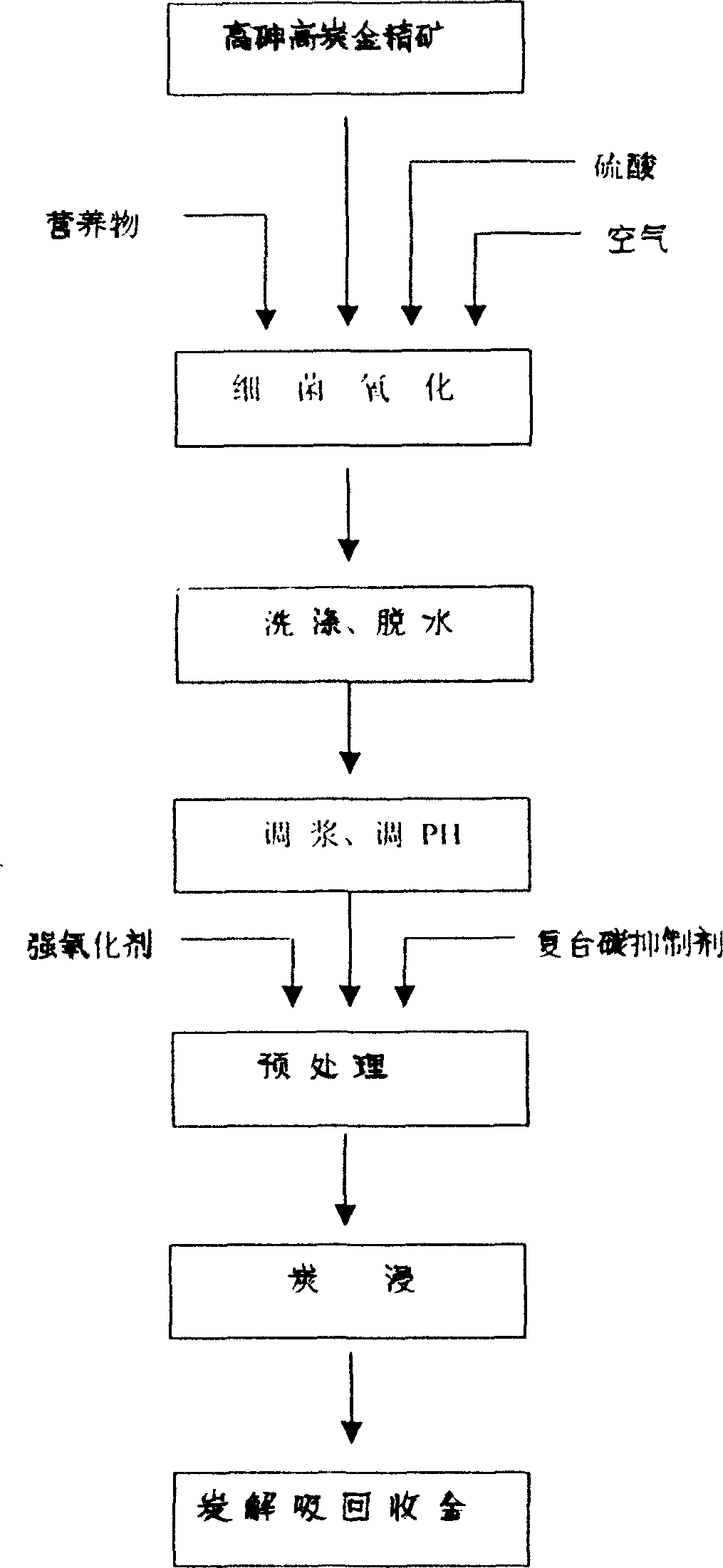

Process for treating high arsenic high carbon gold mine

A processing technology and high-carbon technology, applied in the field of mineral processing, high-arsenic and high-carbon gold ore processing technology, can solve the problems of high processing cost, only 10-50%, high cyanide consumption, prolong the number of cycles, improve poor Influence and improve the effect of recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] specific implementation plan

[0016] Take an arsenic-containing high-carbon ore in Kazakhstan containing about 3% arsenic and 8-10% carbon as an example, adjust the pulp concentration to 15-25%, pH=1-2, and control the growth temperature between 37-45°C , put in the mixed bacteria of Thiobacillus ferrooxidans, Thiobacillus thiooxidans, Helicobacter ferrooxidans and heat-resistant Thiobacillus oxidans, the bacteria use the sulfur and iron in the minerals as food and reproduce, under the action of bacteria, the minerals Sulfur, iron, arsenic, etc. in the liquid are oxidized, the gold-encased minerals are destroyed and dissociated, and the arsenic-containing minerals are decomposed and transformed into the liquid, and then transformed into stable iron arsenate and calcium arsenate that are non-polluting to the environment after neutralization. Precipitation, gold minerals still exist in a solid state and are exposed, and the carbonaceous substances that adsorb gold are pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com