Polymer of PH sensitive type capable of regenerating amphoteric ion for double aqueous phase system and preparation process thereof

A zwitterion and polymer technology, which is applied in the field of pH-sensitive methacrylate polymers and their preparation, can solve problems such as the destruction of biologically active substances, and achieve the effects of maintaining biomass activity and a simple and feasible preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

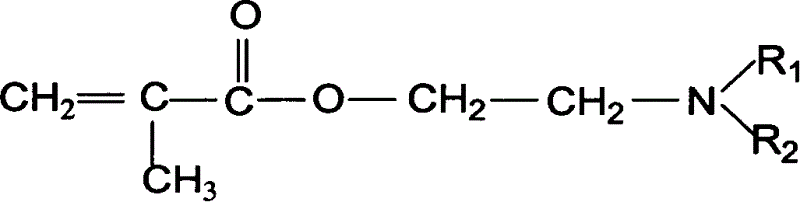

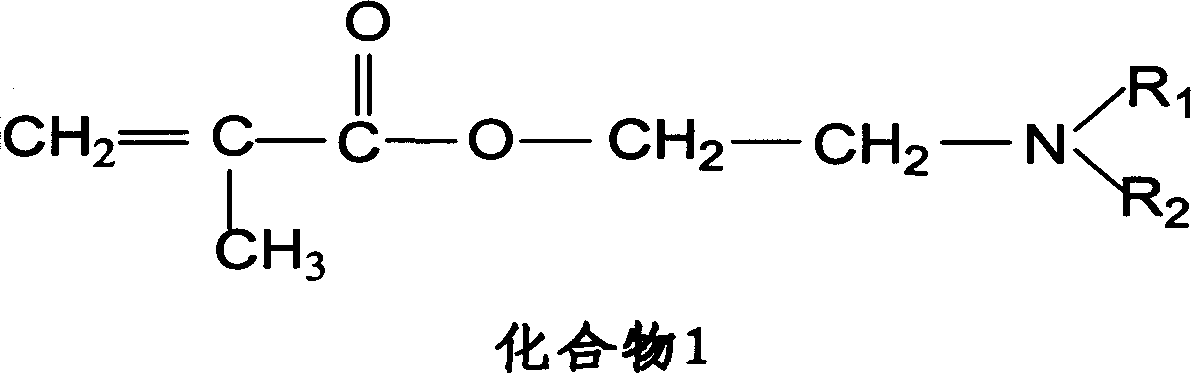

[0025] The synthesis of embodiment 1 ABC trimer:

[0026]Add 33.7ml (0.2mol) 2-methylaminoethyl methacrylate, 16.2ml (0.1mol) tert-butyl methacrylate, 5.3ml (0.05mol) methyl methacrylate in a stoppered Erlenmeyer flask, 200ml of tetrahydrofuran was fully dissolved under stirring, azobisisobutyronitrile AIBN of 2% of the total mass of the three monomers was added as an initiator, and nitrogen was filled to remove oxygen for 15 minutes. The reaction vessel was sealed, and the reaction was carried out at 60° C. with shaking in a water bath at 250 rpm for 24 hours. After the reaction was completed, the product was precipitated with petroleum ether, and the precipitate was dried to constant weight to obtain the final product. Its isoelectric point PI=8.4 was determined. The polymer has a UV absorption maximum at 234 nm.

Embodiment 2

[0028] The mass ratio is 5% ABC trimer aqueous solution P ABC Prepare two aqueous phases with a mass ratio of 10% polyethylene glycol 20000 (PEG20000) aqueous solution, P ABC The optimal volume ratio to PEG20000 solution is 3:2, mix well, and centrifuge to promote phase separation. An appropriate amount of 0.1M NaOH aqueous solution was added to the upper and lower phases respectively to adjust the pH value of the solution, so that the polymer was precipitated at the isoelectric point. Centrifuge, take the supernatant and measure P at 234nm ABC The absorbance, the total recovery of the polymer calculated by the standard curve was 94.5%. Theoretically, it can be used more than 40 times.

Embodiment 3

[0030] Prepare a two-phase aqueous system, the upper phase is P ABC (5%w / w) 3ml, the lower phase is PEG20000 (10%w / w) 2ml, add Na 2 SO 4 Solid, the final concentration is 200mM, distribute the solute BSA (bovine serum albumin), the initial concentration is 0.6mg / ml, mix and centrifuge at low speed to promote the formation of two phases, and measure the absorbance of BSA in the upper and lower phases at 280nm , the calculated distribution coefficient of BSA was 12.5. It is proved that the polymer can be used in two-phase extraction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com