White bias to blue paster type light-emitting diode and producing method thereof

A white-to-blue patch type, light-emitting diode technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of poor luminous efficiency, unsatisfactory, and unsatisfactory, and achieve small size, reduced manufacturing cost, and energy saving. significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

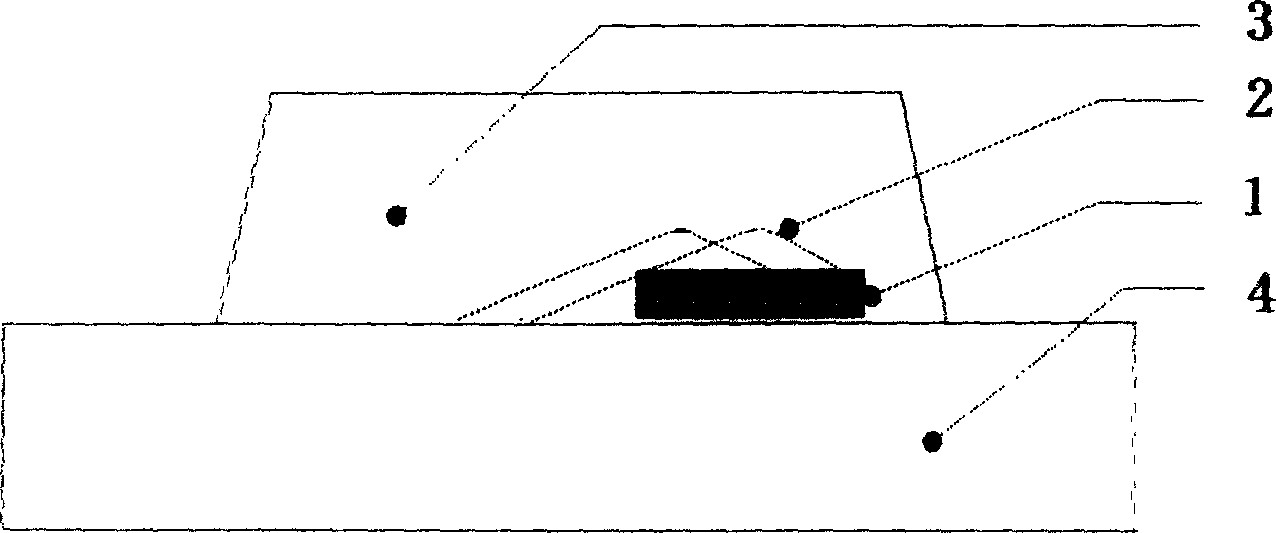

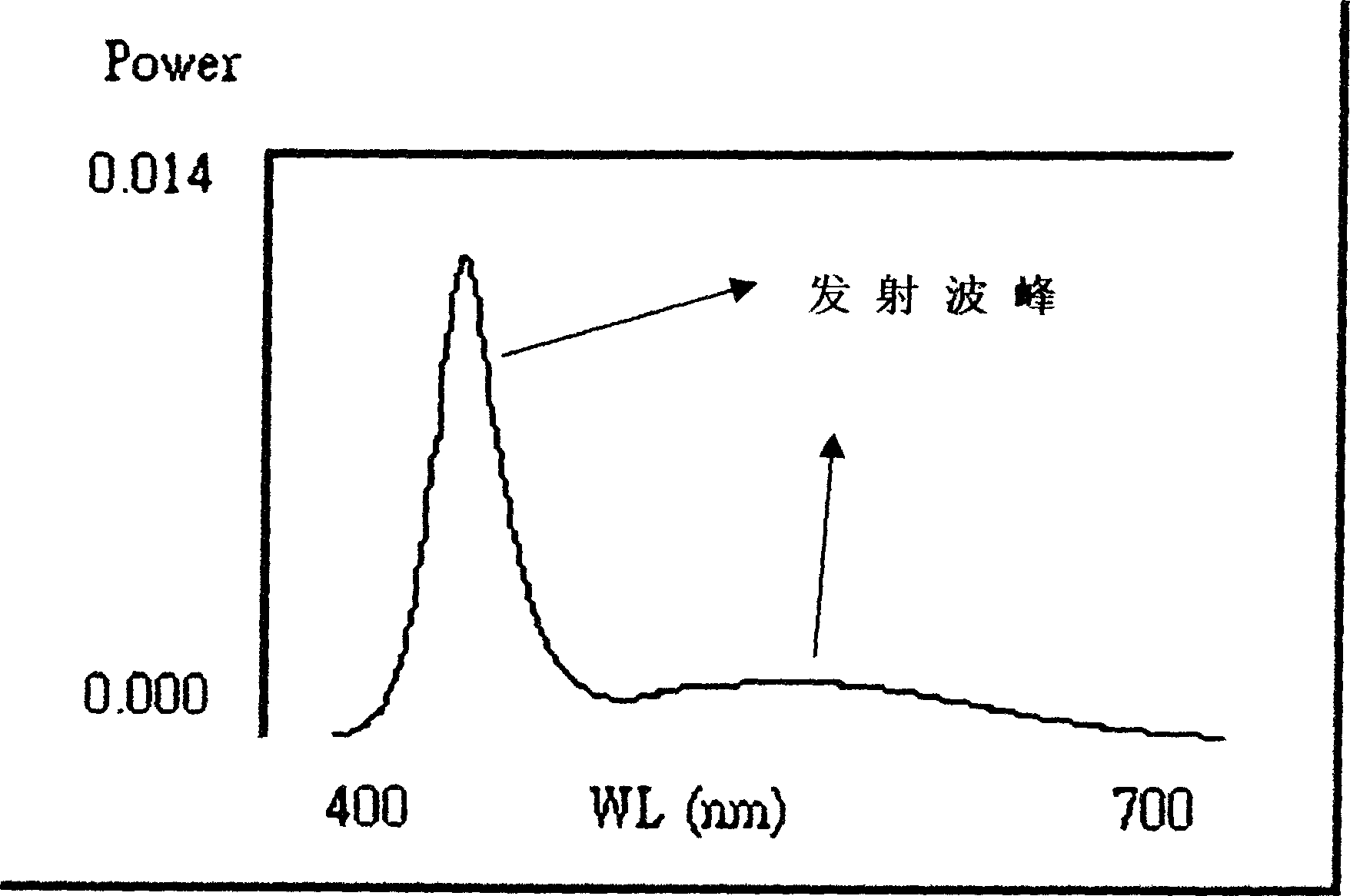

[0027] Embodiment 1: as figure 1 As shown, the white bluish SMD LED includes a blue chip 1, a wire 2, a printed circuit board 4 and a fluorescent rubber cake 3, the fluorescent rubber cake 3 covers the blue chip 1, and the wire 2 connects the positive and negative of the blue chip 1. The pole is connected to the printed circuit board 4, the fluorescent rubber cake 3 is epoxy resin containing yellow phosphor powder, the blue light chip 1 is an ordinary Ni / Au nitride blue light emitting diode chip, and its wavelength is 462.5-465nm, and the fluorescent rubber cake 3 The yellow phosphor powder is cerium-doped yttrium aluminum garnet phosphor powder, the thickness of the fluorescent rubber cake 3 is 0.3 mm, and the raw material of each 100 grams of the fluorescent rubber cake 3 is: 9 grams of yellow phosphor powder (where Dysprosium (Dy) is 0.03 grams), 91 grams of epoxy resin, the principle of the present invention is to excite the yellow fluorescent powder with a 462.5-465nm blu...

Embodiment 2

[0028] Embodiment 2: the thickness of fluorescent rubber cake 3 is 0.35mm, and the raw material of every 100 grams of fluorescent rubber cake 3 is: yellow fluorescent powder 6 grams (wherein dysprosium (Dy) 0.04 grams), epoxy resin 94 grams, all the other are the same as embodiment 1.

Embodiment 3

[0029] Embodiment 3: The technological process of the white bluish patch type light-emitting diode is as follows: a. expand the core of the original blue light disc to make the spacing meet the production requirements, b. put silver glue on the 4 circuits of the printed circuit board for pasting Blu-ray chip 1, c. paste the blue-ray chip 1 on the silver glue, and then cure it at a temperature of 100°C-180°C, d. clean it with plasma ion spraying, restore the surface of the printed circuit board 4 and the blue-ray chip 1, e. Use ultrasonic welding wires 2 to connect the positive and negative poles of the blue light chip 1 to the printed circuit board 4, f. hot press with epoxy resin containing yellow phosphor, and cover the blue light chip 1 to protect the circuit and the blue light chip 1, g. At 100°C-180°C temperature, fully cure the epoxy resin, h. Level the PCB 4, attach the adhesive tape on the back of the PCB 4, then stick it on the cutting ring, and cut it into the final p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Brightness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com