Method for preparing natural food antiseptic chitin and its use

A technology of natural food and chitosan, which is applied in application, food preservation, food science, etc., can solve the problems of chitosan color deepening, product reduction, poor hydrolysis selectivity, etc., achieve strong antibacterial performance, and solve the problem of heat Decomposition and less side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

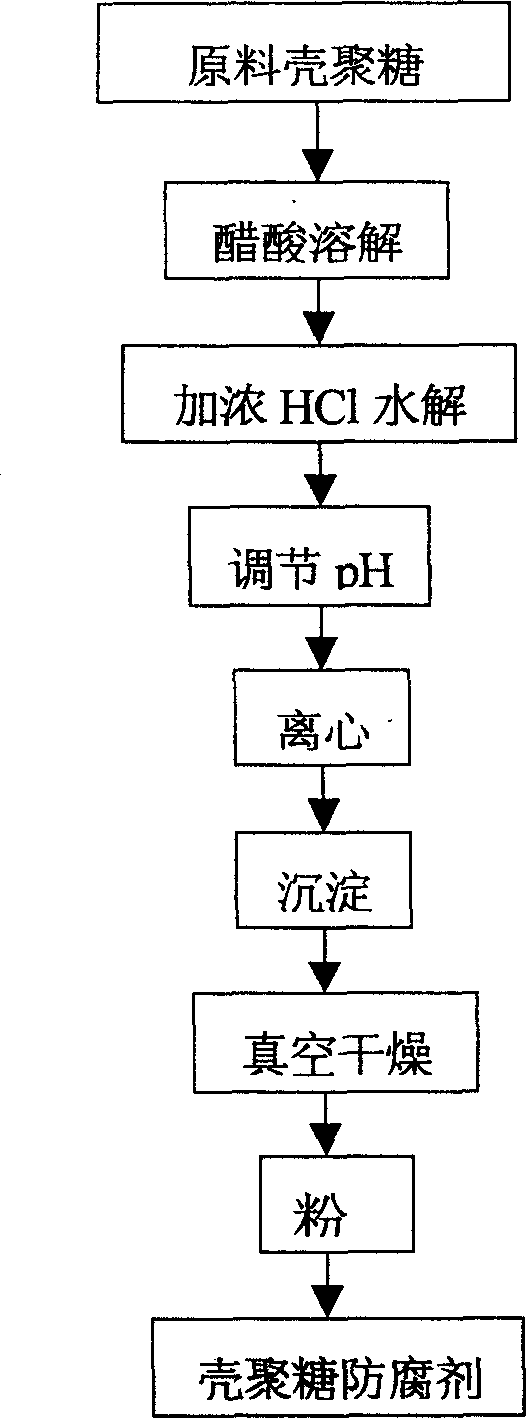

[0023] Using chitosan with a degree of deacetylation above 85% and a viscosity-average molecular weight range of 200,000 to 800,000 as a raw material, dissolve chitosan in 1% acetic acid solution to make the mass concentration of chitosan reach 1%, and stir completely After dissolving, add concentrated hydrochloric acid into the chitosan solution according to the chitosan solution / concentrated hydrochloric acid volume ratio of 20:1, heat up to 60° C., and hydrolyze for 10 hours. After the reaction is finished, adjust the pH with 10mol / L NaOH solution to make the pH of the solution reach 7.0-8.0, centrifuge, wash the precipitate with clean water, and then centrifuge to remove water, evenly disperse the precipitate in a stainless steel plate and place it for vacuum drying Oven, vacuum drying, drying temperature 40 ° C, vacuum 0.095MPa, dried to a moisture content of 10% or less. After drying, the chitosan is taken out and pulverized in a pulverizer to obtain a powdered chitosan ...

Embodiment 2

[0025] Using chitosan with a degree of deacetylation above 85% and a viscosity-average molecular weight range of 200,000 to 800,000 as a raw material, dissolve chitosan in 2% acetic acid solution to make the mass concentration of chitosan reach 3%, and stir completely After dissolving, add concentrated hydrochloric acid into the chitosan solution according to the chitosan solution / concentrated hydrochloric acid volume ratio of 20:1, heat up to 80° C., and hydrolyze for 8 hours. After the reaction is finished, adjust the pH with 10mol / L NaOH solution to make the pH of the solution reach 7.0-8.0, centrifuge, wash the precipitate with clean water, and then centrifuge to remove water, evenly disperse the precipitate in a stainless steel plate and place it for vacuum drying Oven, vacuum drying, drying temperature 60 ° C, vacuum 0.085MPa, dried to less than 10% moisture content. After drying, the chitosan is taken out and pulverized in a pulverizer to obtain a powdered chitosan pres...

Embodiment 3

[0027]Using chitosan with a degree of deacetylation above 85% and a viscosity-average molecular weight range of 200,000 to 800,000 as a raw material, dissolve chitosan in 3% acetic acid solution to make the mass concentration of chitosan reach 5%, and stir completely After dissolving, add concentrated hydrochloric acid into the chitosan solution according to the chitosan solution / concentrated hydrochloric acid volume ratio of 20:1, heat up to 90° C., and hydrolyze for 6 hours. After the reaction is finished, adjust the pH with 10mol / L NaOH solution to make the pH of the solution reach 7.0-8.0, centrifuge, wash the precipitate with clean water, and then centrifuge to remove water, evenly disperse the precipitate in a stainless steel plate and place it for vacuum drying Oven, carry out vacuum drying, drying temperature 80 ℃, vacuum degree 0.08MPa, dry to moisture content below 10%. After drying, the chitosan is taken out and pulverized in a pulverizer to obtain a powdered chitos...

PUM

| Property | Measurement | Unit |

|---|---|---|

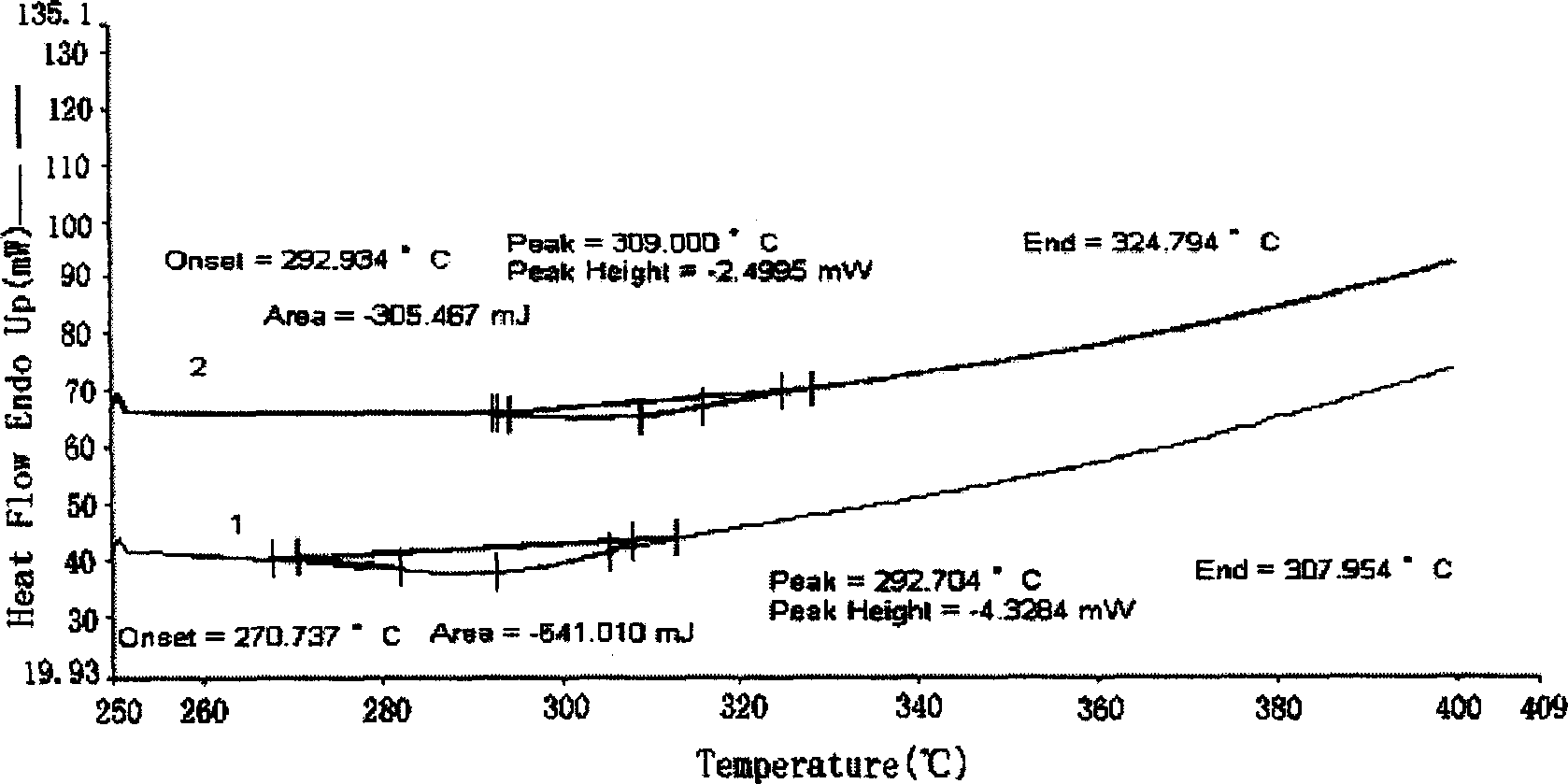

| Thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com