Non-pollution nuisance composite mycelium active forage and production thereof

A technology of compound bacteria and feed, applied in the direction of animal feed, animal feed, application, etc., can solve the problems of polluting feed, endangering environmental sanitation, endangering physical and mental health, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

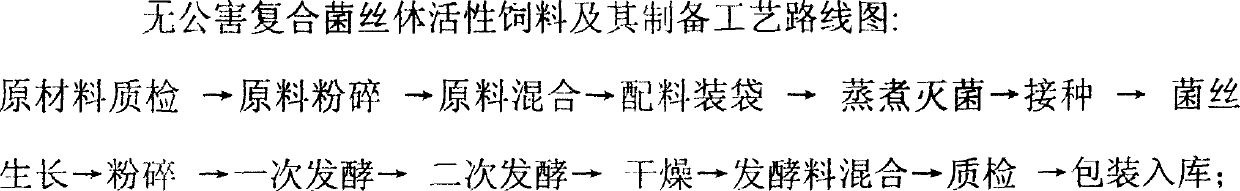

Method used

Image

Examples

Embodiment 1

[0030] A. Take 90 parts each of clean wheat straw, wheat bran, rice straw, rice bran, sorghum stalk, grain stalk, and vegetable stalk;

[0031] B. Mixing of raw materials: Weigh and weigh all kinds of pulverized raw materials into the mixer for full mixing, each batch / machine is 5 tons, and the mixing is not less than 30 minutes;

[0032] C. Bagging of ingredients: 90 parts of mixed raw materials, 60 parts of edible water, mix all the edible water evenly and immerse in the mixture; pile up 0.5-0.7M high, cover with thick 0.1MM plastic cloth, let the mixture mature naturally for 2- 4 days; then use 3 parts of honey or brown sugar, 50 parts of drinking water, dissolve the molasses in the drinking water, mix all the molasses water evenly and immerse in the natural curing material, then pack into bags, each bag weighing 800-1000g;

[0033] D. Retort sterilization: put the packed bag into the container to retort and sterilize, the sterilization pressure is 1.0kg / cm, and the time is...

Embodiment 2

[0044] 1) Take clean bean stalks, rape stalks, peanut seedlings, peanut skins, red seedlings, corncobs, vegetable leaves, rice bran, and 93 parts of crushed melon seedlings;

[0045] 2) Mixing of raw materials: Weigh the same amount of crushed raw materials and send them to the mixer for full mixing. Each batch / machine is 5 tons, and the mixing is not less than 30 minutes;

[0046] 3) Bagging of ingredients: 93 parts of mixed raw materials, 50 parts of edible water, mix all the edible water evenly and immerse in the mixture; pile up 0.5-0.7M high; cover with thick 0.08MM plastic cloth; let the mixture naturally mature for 3 days ; Then use 3 parts of brown sugar and 60 parts of drinking water, dissolve the sugar in the drinking water, mix all the sugar water evenly and immerse in the natural curing material, then pack into bags, each bag weighing 800-1000g;

[0047] 4) Retort sterilization: Put the packed bag into the container to retort and sterilize, the sterilization pressu...

Embodiment 3

[0058] (1) Take 91 parts each of clean dried river weeds, dried water hyacinth, dried leaves and dried weeds;

[0059] (2) Mixing of raw materials: Weigh and weigh all kinds of pulverized raw materials into the mixer for full mixing, each batch / machine is 5 tons, and the mixing is not less than 30 minutes;

[0060] (3) Bagging of ingredients: 90 parts of mixed raw materials, 55 parts of edible water, mix all the edible water evenly and immerse in the mixture; pile up 0.5-0.7M high, cover with thick 0.1MM plastic cloth, let the mixture mature naturally for 2 -4 days; then use 3 parts of honey or brown sugar, 60 parts of edible water, dissolve the molasses in the drinking water, mix all the molasses water evenly and immerse in the natural curing material, then pack into bags, each bag weighing 800-1000g;

[0061] (4) Retort sterilization: put the packed bag into the container for retort sterilization, the sterilization pressure is 1.5kg / cm, and the time is 20 minutes;

[0062] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com