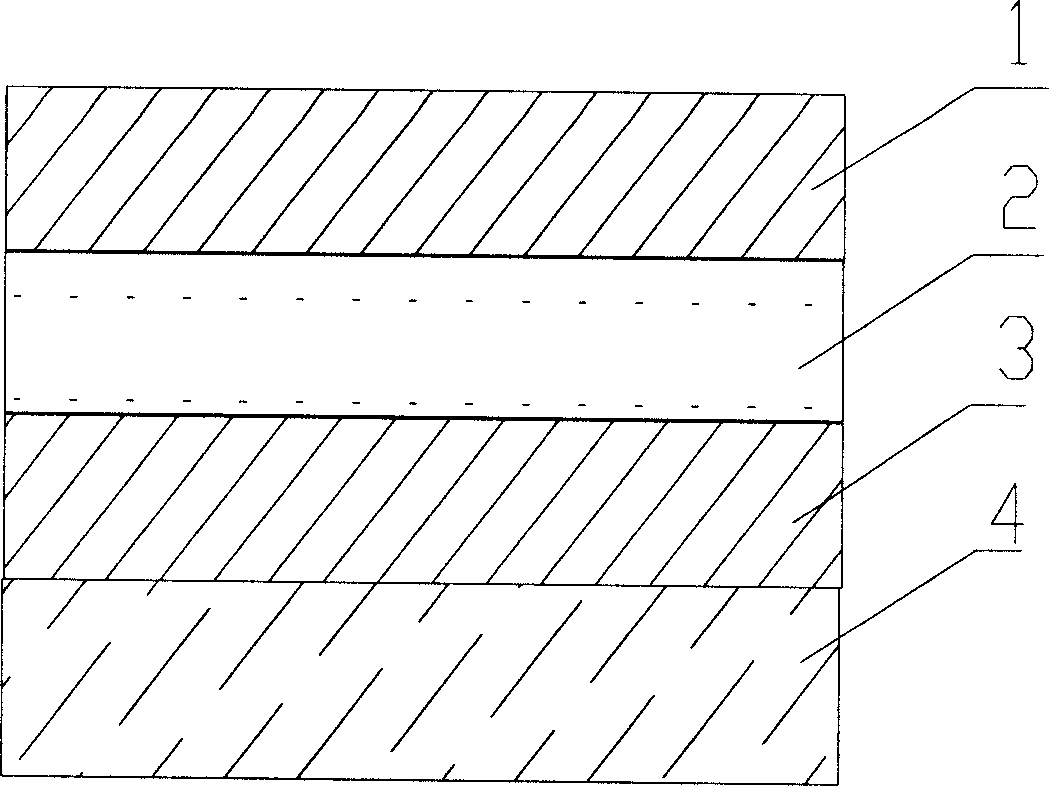

Carbon-fiber reinforced silicon carbide composite material antioxidation coating layer and its preparation method

A technology for composite materials and composite components, which is applied in the field of carbon fiber reinforced silicon carbide composite anti-oxidation coating and its preparation, can solve the problems of no protection effect, poor effect, narrow coating protection temperature range, etc., and achieve good oxidation resistance properties, reducing the rate of oxidation weight loss, and improving the effect of antioxidant protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

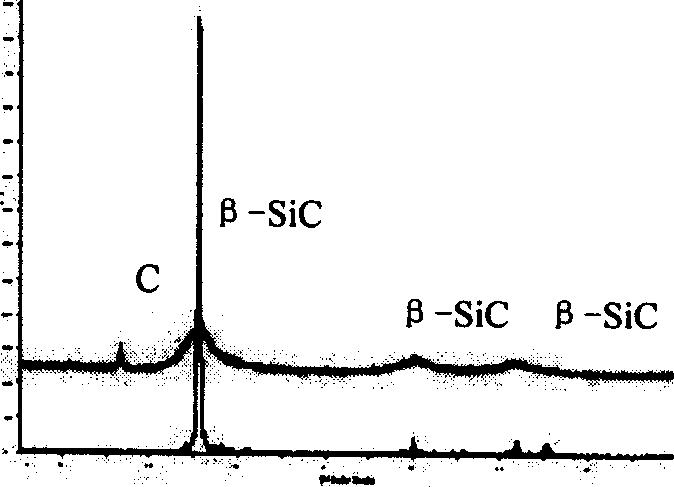

Method used

Image

Examples

Embodiment 1

[0062] Step 1: Preparation of SiC bonding layer: Rinse the Cf / SiC composite member (50mm×5mm×4mm) prepared by the polymer precursor polycarbosilane (PCS) impregnation cracking process, dry it and bind it with carbon fiber Place in a chemical vapor deposition furnace, raise the temperature of the chemical vapor deposition furnace to 900°C, and then pass H 2 , with H 2 Bring trichloromethylsilane (MTS) into the chemical vapor deposition furnace, feed Ar as the dilution and protective gas, H 2 The flow rate was kept at 500ml / min, the Ar flow rate was kept at 500ml / min, the furnace pressure was kept at 600Pa-800Pa by vacuuming, and the deposition time was 20 hours to prepare the SiC adhesive layer.

[0063] Step 2: Preparation of self-healing layer: Weigh CB 4 、MoSi 2 30 grams each, Y 2 o 3 10 grams of fine powder, mixed and placed in a ball mill jar for ball milling for 2 hours. After ball milling, the mixed powder is mixed with 30 grams of polyvinyl alcohol, and an appropr...

Embodiment 2

[0066] Step 1: Preparation of the SiC bonding layer: raise the temperature of the chemical vapor deposition furnace to 1300°C, and then pass in H 2 , with H 2 Bring trichloromethylsilane (MTS) into a chemical vapor deposition furnace, and pass Ar as a dilution and protection gas. h 2 The flow rate is maintained at 800ml / min, the Ar flow rate is maintained at 400ml / min, and the furnace pressure is controlled at 900Pa-1000Pa by vacuuming. Deposition time 10 hours.

[0067] Step 2 is the same as step 2 of embodiment 1.

[0068] Step 3 is the same as Step 3 in Example 1.

Embodiment 3

[0070] Step 1 is the same as Step 1 in Example 1.

[0071] Step 2: Weigh CB 4 、MoSi 2 20 grams each, Y 2 o 3 10 grams of fine powder, mixed and placed in a ball mill jar for ball milling for 2 hours. After ball milling, the mixed powder is mixed with 20 grams of polyvinyl alcohol, and an appropriate amount of water is added to make a slurry. Apply the slurry on the surface of the Cf / SiC composite member that has prepared the SiC bonding layer, and dry it under the irradiation of infrared lamps. Firing of the self-healing layer: place the sample dried under the infrared irradiation on In a sintering furnace protected by an inert atmosphere at normal pressure, the temperature was raised to 1500°C at a heating rate of 1°C / min, and kept for 30 minutes. After cooling down, a sample containing a self-healing layer with a uniform coating was taken out.

[0072] Step 3 is the same as step 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com