Isooctanoic acid mercapto alcohol ester based organic tin compound and its preparation method and use

A technology of mercaptoethanol ester and isooctanoic acid, applied in the direction of tin organic compounds, etc., can solve the problems of high investment cost, pollution, complicated process, etc., and achieve the effects of reducing investment, simplifying process and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

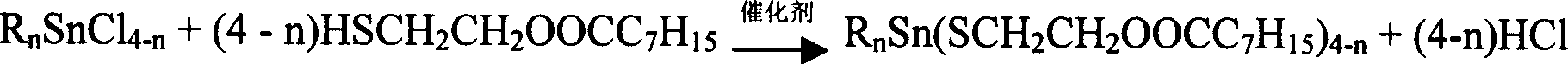

Method used

Image

Examples

Embodiment 1

[0056] Preparation of octyltin bis(mercaptoethanol isooctanoate):

[0057] (1) isooctanoic acid mercaptoethanol ester, dioctyl tin dichloride and xylene are added to the reactor, heated to reflux at 90 DEG C, and 1M NaOH solution is added dropwise simultaneously, and the pH value of the control reaction solution is 6;

[0058] The volume (ml) of each component is as follows (calculated by the total volume of 100ml):

[0059] Isooctanoate mercaptoethanol 15

[0060] Dioctyltin dichloride 15

[0061] 1M NaOH solution 12

[0062] Xylene 58

[0063] (2) the resultant is divided into two layers, and the water layer is discarded through liquid separation, and the organic layer is retained;

[0064] (3) Distillation under reduced pressure, under the condition of -0.07MPa, the organic layer was distilled under reduced pressure. All fractions below 60°C were discarded to remove solvent and some low-boiling impurities in the reaction system. Dioctyltin bis(mercaptoethanol isooctan...

Embodiment 2

[0066] Preparation of (β-ethoxycarbonylethyl)tin bis(mercaptoethanol isooctanoate)

[0067] (1) Add isooctanoic acid mercaptoethanol ester, bis(β-ethoxycarbonylethyl) tin dichloride and xylene into the reactor, heat under reflux at 90°C, and dropwise add 1M NaOH solution to control the pH of the reaction solution value at 6;

[0068] The volume (ml) of each component is as follows (calculated by the total volume of 100ml):

[0069] Isooctanoate mercaptoethanol 15

[0070] Di(β-ethoxycarbonylethyl)tin dichloride 15

[0071] 1M NaOH solution 12

[0072] Xylene 58

[0073] (2) the resultant is divided into two layers, and the water layer is discarded through liquid separation, and the organic layer is retained;

[0074] (3) Distillation under reduced pressure, under the condition of -0.07MPa, the organic layer was distilled under reduced pressure. All fractions below 60°C were discarded to remove solvent and some low-boiling impurities in the reaction system. The PVC heat ...

Embodiment 3

[0076] Preparation of dimethyltin bis(mercaptoethanol isooctanoate):

[0077] (1) Add mercaptoethanol isooctanoate, dimethyl tin dichloride and cyclohexane into the reactor, heat under reflux at 80°C, and dropwise add 1M NaHCO 3 solution, control the pH value of the reaction solution at 7;

[0078] The volume (ml) of each component is as follows (calculated by the total volume of 100ml):

[0079] Isooctanoate mercaptoethanol 10

[0080] Dimethyltin dichloride 8

[0081] 1MNaHCO 3 Solution 10

[0082] Cyclohexane 72

[0083] (2) the resultant is divided into two layers, and the water layer is discarded through liquid separation, and the organic layer is retained;

[0084] (3) Underpressure distillation, under the condition of -0.05MPa, the organic layer was subjected to reduced pressure distillation.

[0085] All fractions below 65°C were discarded to remove solvent and some low-boiling impurities in the reaction system.

[0086] Dimethyltin bis(mercaptoethanol isooctan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com