Semiconductor device and manufacturing method thereof

A manufacturing method and semiconductor technology, applied in the direction of semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve problems such as process growth and achieve the effects of suppressing chip area, suppressing increase, and high sheet resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

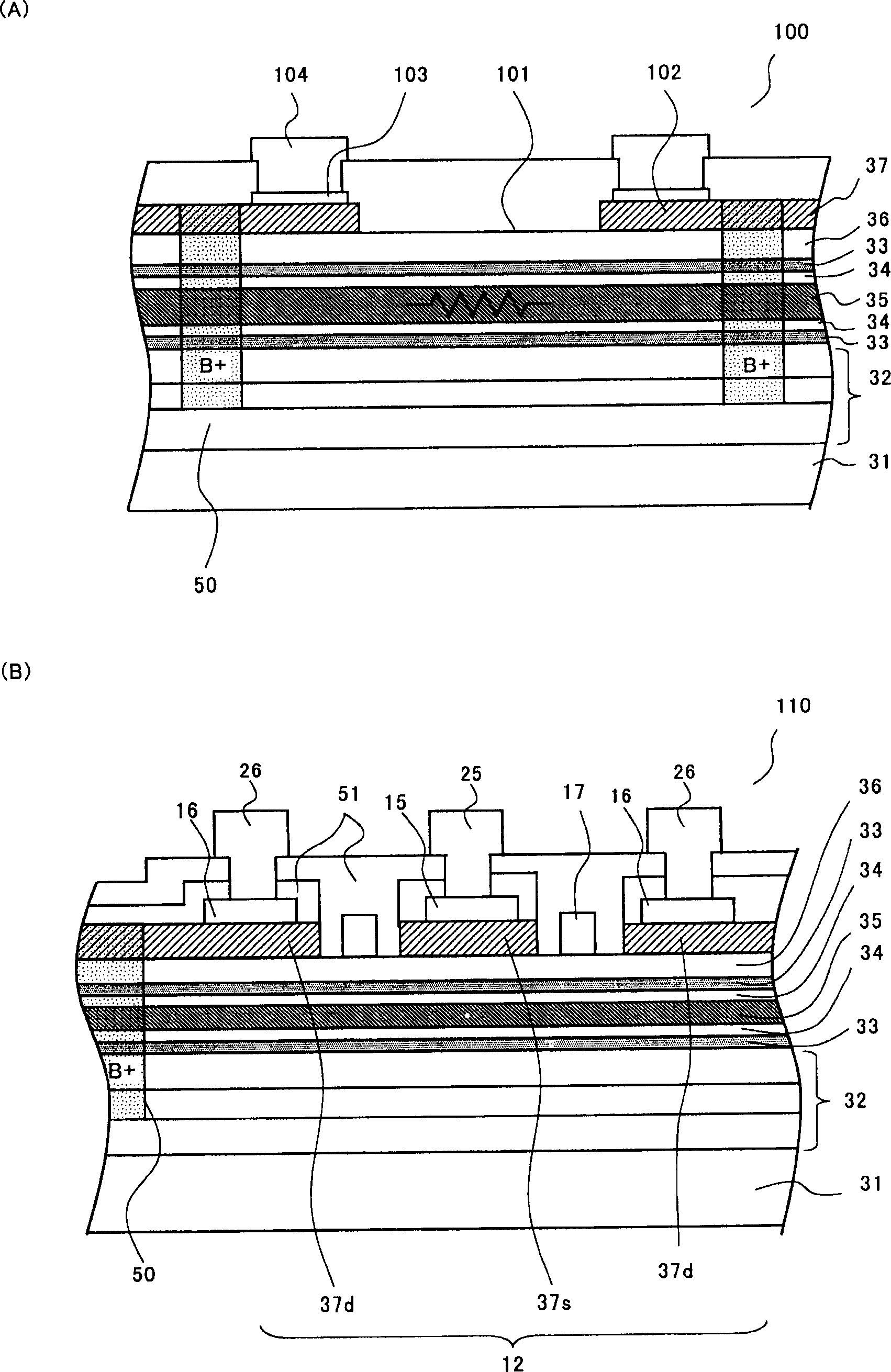

[0103] Embodiments of the present invention will be described in detail below.

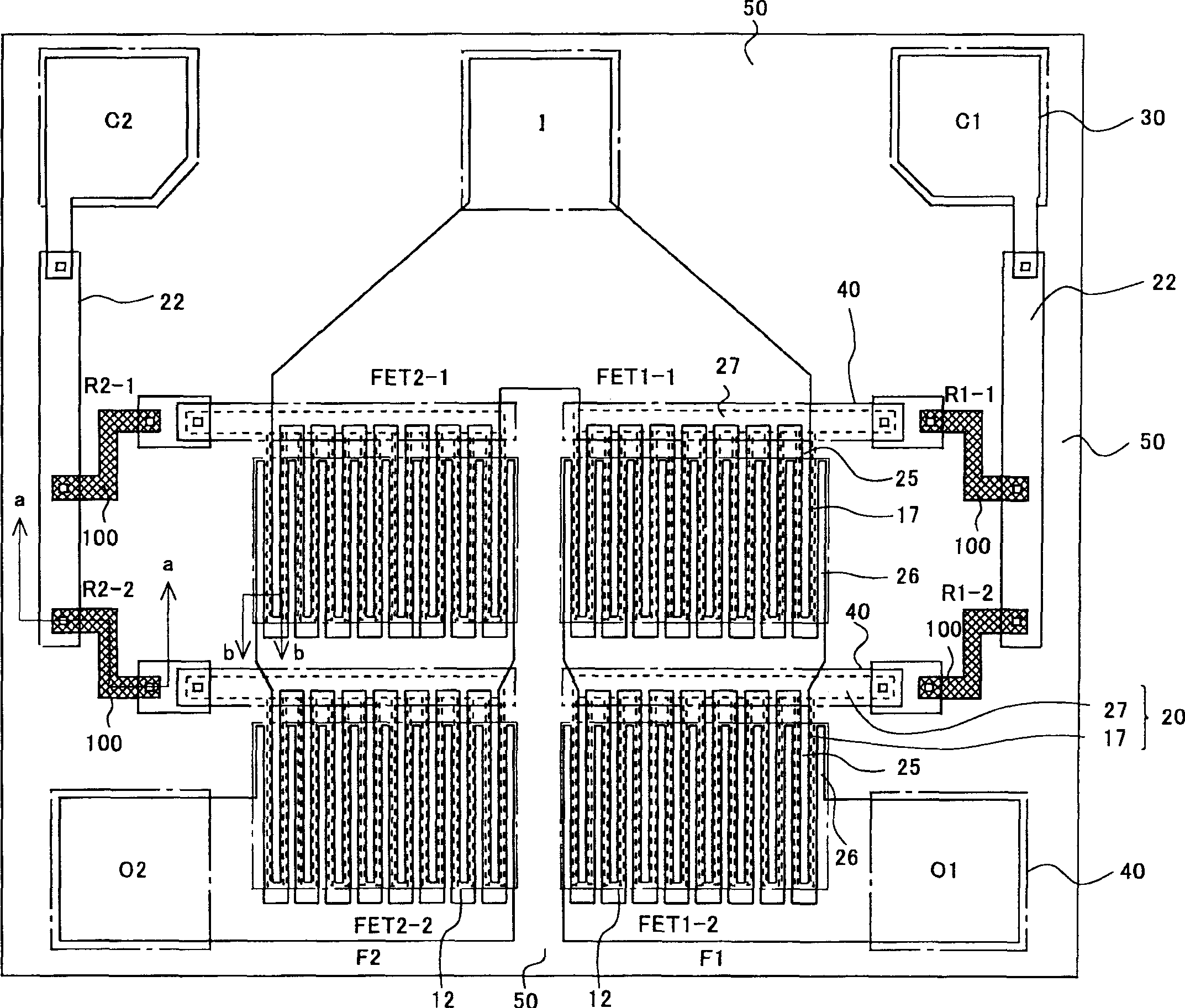

[0104] First, refer to figure 1 and figure 2 A first embodiment of the present invention will be described.

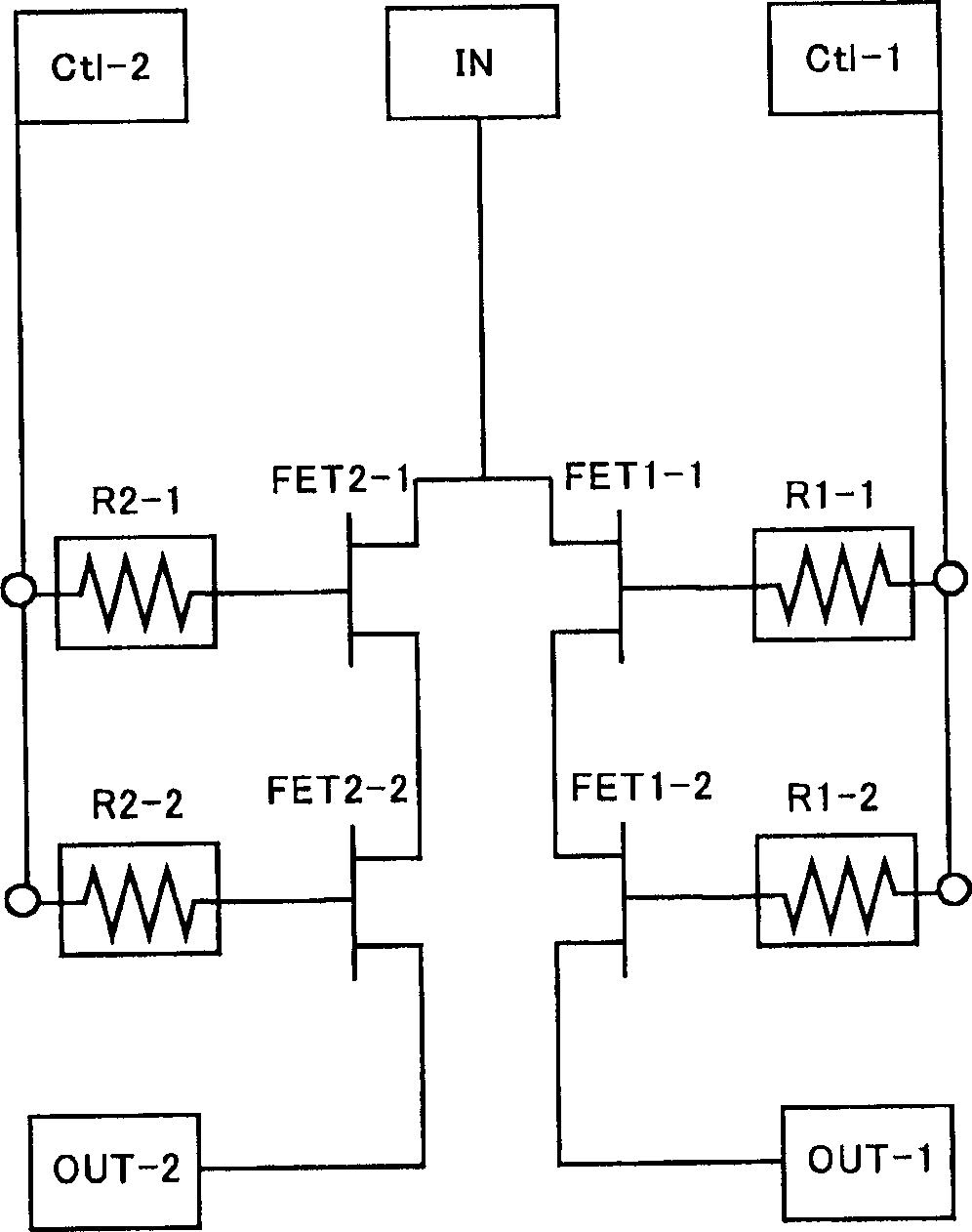

[0105] figure 1 is a diagram showing a semiconductor device in which HEMTs and resistor elements are monolithically integrated. Here, a switching circuit device called SPDT (Single Pole Double Throw) is shown, and a device in which HEMTs (FETs) are connected in series in multiple stages for high-power applications will be described as an example.

[0106] The control signals applied to the first and second control terminals Ctl-1 and Ctl-2 are complementary signals, which turn on the FET group on the side to which the H level signal is applied, and transfer the input signal applied to the common input terminal IN to any output terminal. Resistors are provided to prevent leakage of high-frequency signals from the DC potentials of the control terminals Ctl-1 and Ctl-2 connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com