Epitaxial growing technology of III class nitride semiconductor on silicon substrate

A nitride semiconductor and epitaxial growth technology, which is applied in the manufacture of semiconductor devices, semiconductor lasers, semiconductor/solid-state devices, etc., can solve problems such as high defect density and cracks in thick epitaxial layers, and achieve low dislocation density and easy operation. Effect of controlling and improving luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] 1. Use the following cleaning solution H for the single-sided or double-sided polished silicon wafer 2 SO 4 :H 2 o 2 , NH 4 OH:H 2 o 2 :H 2 O, HCl:H 2 o 2 :H 2 O, HF:H 2 O and rinse with copious amounts of cold and hot deionized water; spin dry.

[0019] 2. Put the cleaned and dried silicon wafer into the PECVD reaction chamber to deposit SiO 2 ; Or put it into an oxidation furnace to oxidize to the required thickness of the oxide layer.

[0020] 3. Deposit SiO 2 Or put the oxidized silicon wafer into the MOCVD reaction chamber immediately after taking it out.

[0021] 4. Rapidly raise the temperature of MOCVD to 1000°C ~ 1150°C, while passing H 2 .

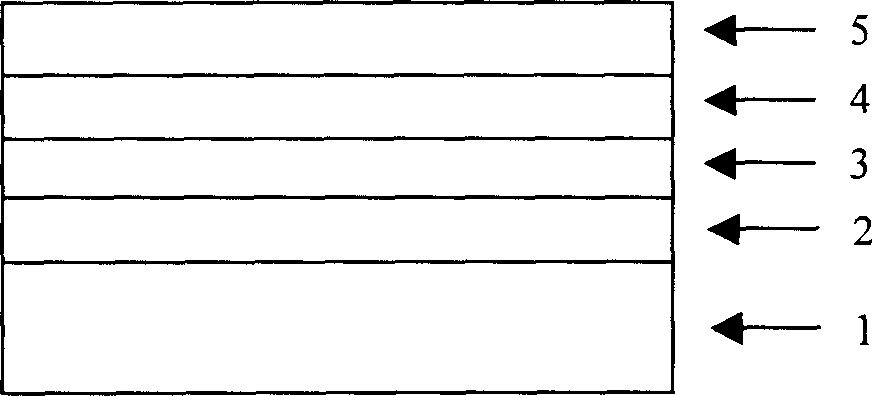

[0022] 5. Grow the buffer layer 3AlN, the growth time is 200 seconds to 450 seconds, and pass NH at the same time 3 and trimethylaluminum (TMAl).

[0023] 6. Grow the gradient layer 4 rich in Ga-GaN, the growth time is about 200 seconds to 800 seconds, pass NH 3 and trimethylgallium (TMG); the flux of tri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com