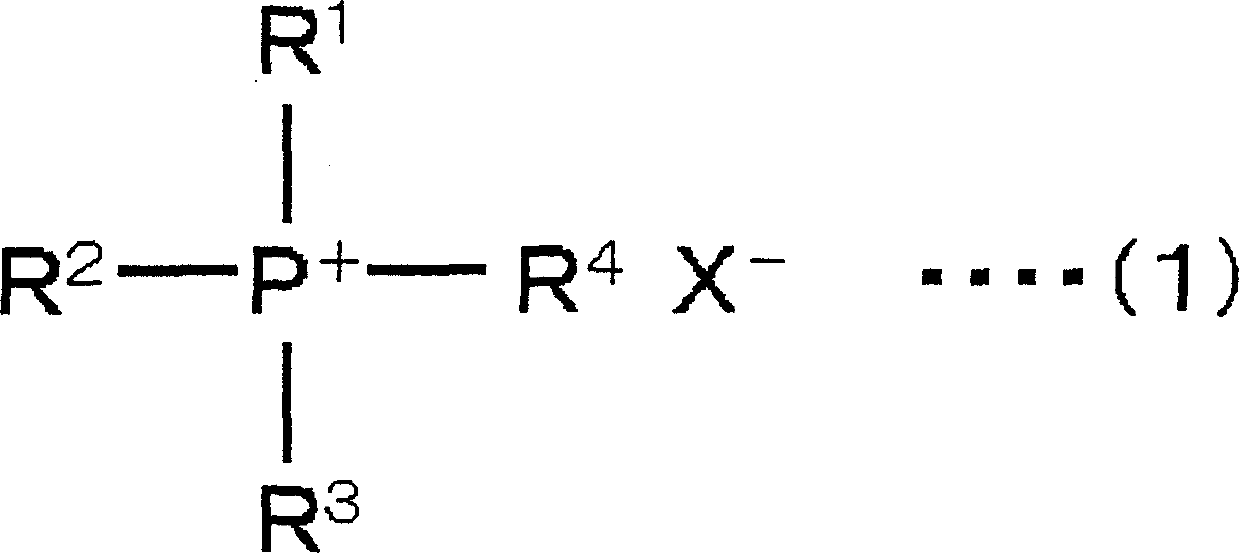

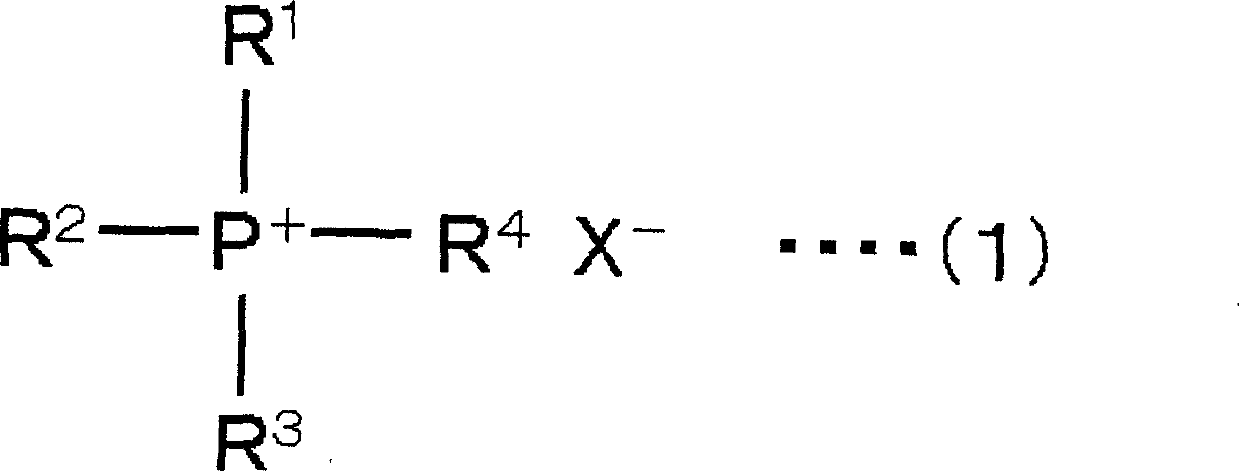

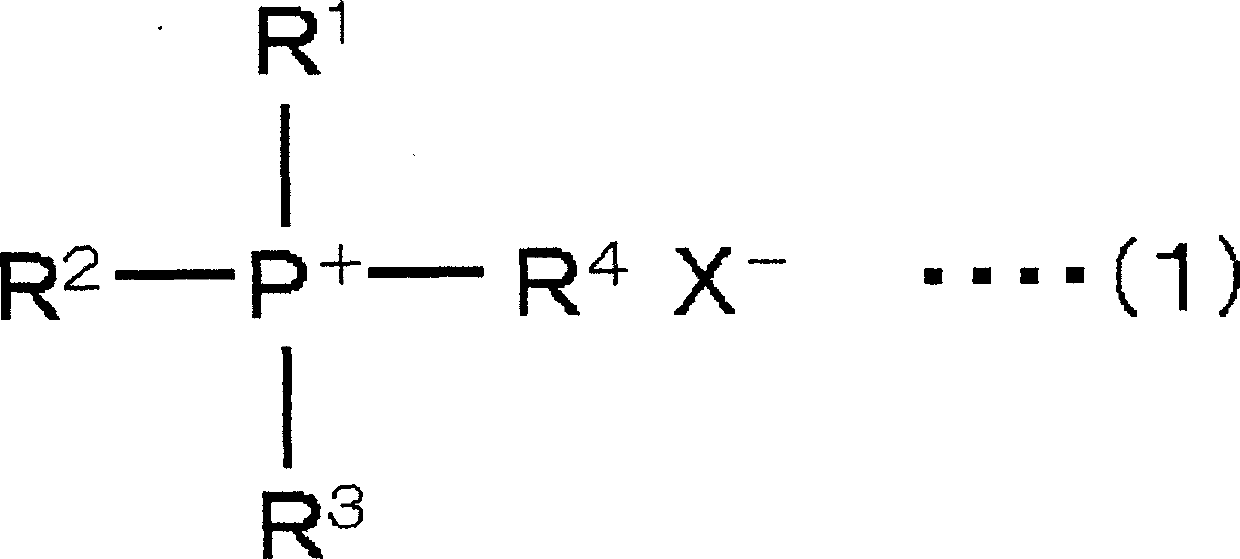

Antistatic agents for resins, antistatic resin compositions, and moldings of antistatic resins

A technology of resin composition and antistatic agent, applied in the field of phosphonium salt antistatic agent, can solve problems such as inability to use, and achieve the effect of excellent antistatic property and excellent antistatic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0102]

[0103] A 50% aqueous solution (manufactured by Nippon Chemical Industry Co., Ltd.) of tri-n-butyl-n-hexadecylphosphonium chloride (1,783 g (1.924 mol)) was diluted with 9 L of ion-exchanged water. 222.0 g (2.024 mol) of sodium borofluoride (manufactured by Morita Chemical Industry Co., Ltd.) was dissolved in 1 L of ion-exchanged water. After filtering the insoluble matter with filter paper, it added dropwise at room temperature (15 degreeC) to the phosphonium salt aqueous solution. After the dropwise addition was completed, it was aged at room temperature (25° C.) for 60 minutes.

[0104] Next, the resulting slurry was filtered with a centrifuge. 6 L of ion-exchanged water was added to the filtered crystals, stirred at room temperature for 15 minutes, and then filtered with a centrifuge. The filtrate was titrated with an aqueous silver nitrate solution, and the slurry was washed and refiltered repeatedly until the halogen was negative.

[0105] Then, it dried at ...

preparation example 2

[0110]

[0111] In addition to using 178.3g (0.192 moles) of a 50% aqueous solution of tri-n-butyl-n-tetradecylphosphonium chloride (Nippon Kagaku Kogyo Co., Ltd.) and 22.20 g (0.202 moles) of sodium borofluoride (manufactured by Morita Chemical Industry Co., Ltd.) , Carried out the same operation as Preparation Example 1 to obtain tri-n-butyl n-tetradecylphosphonium 4 boron fluoride.

[0112] Melting point: 53°C (light transmission melting point measuring device)

[0113] Decomposition temperature: 423°C (TG-DTA)

[0114] Halogen content: 78ppm (silver nitrate titration)

[0115] Residual moisture content: 0.18% (Karl Fischer moisture meter)

preparation example 3

[0116]

[0117] Except using 50% aqueous solution of 2779.3 g (3.0 moles) of tri-n-butyl-n-hexadecylphosphonium chloride and replacing sodium borofluoride with 579.8 g (3.15 moles) of potassium fluoride phosphate, the same procedure as in Preparation Example 1 was carried out. The operation obtained tri-n-butyl n-hexadecylphosphonium 6 phosphorus fluoride.

[0118] Melting point: 50.0°C (light transmission melting point measuring device)

[0119] Decomposition temperature: 369.7°C (TG-DTA)

[0120] Halogen content: 89ppm (silver nitrate titration)

[0121] Residual moisture content: 0.21% (Karl Fischer moisture meter)

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com