Microcomputer-controlled high-power all-solid-state middle and high frequency induction heating equipment

A technology of high-frequency induction heating and microcomputer control, applied in induction heating, induction heating control, etc., can solve the problems of radiation damage, bulky, uneven heating, etc., and achieve rapid monitoring and protection, low intelligence, and reliability high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

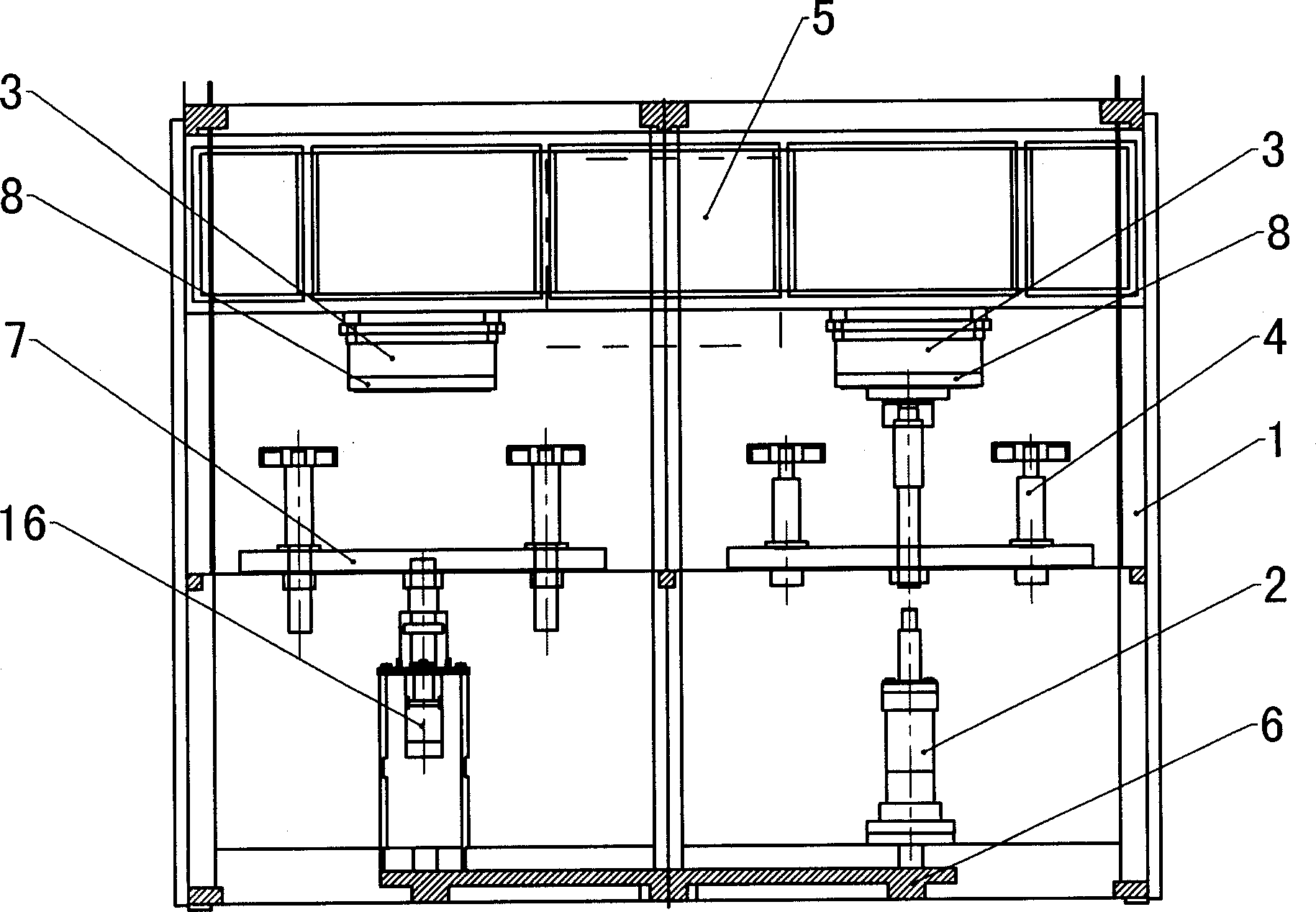

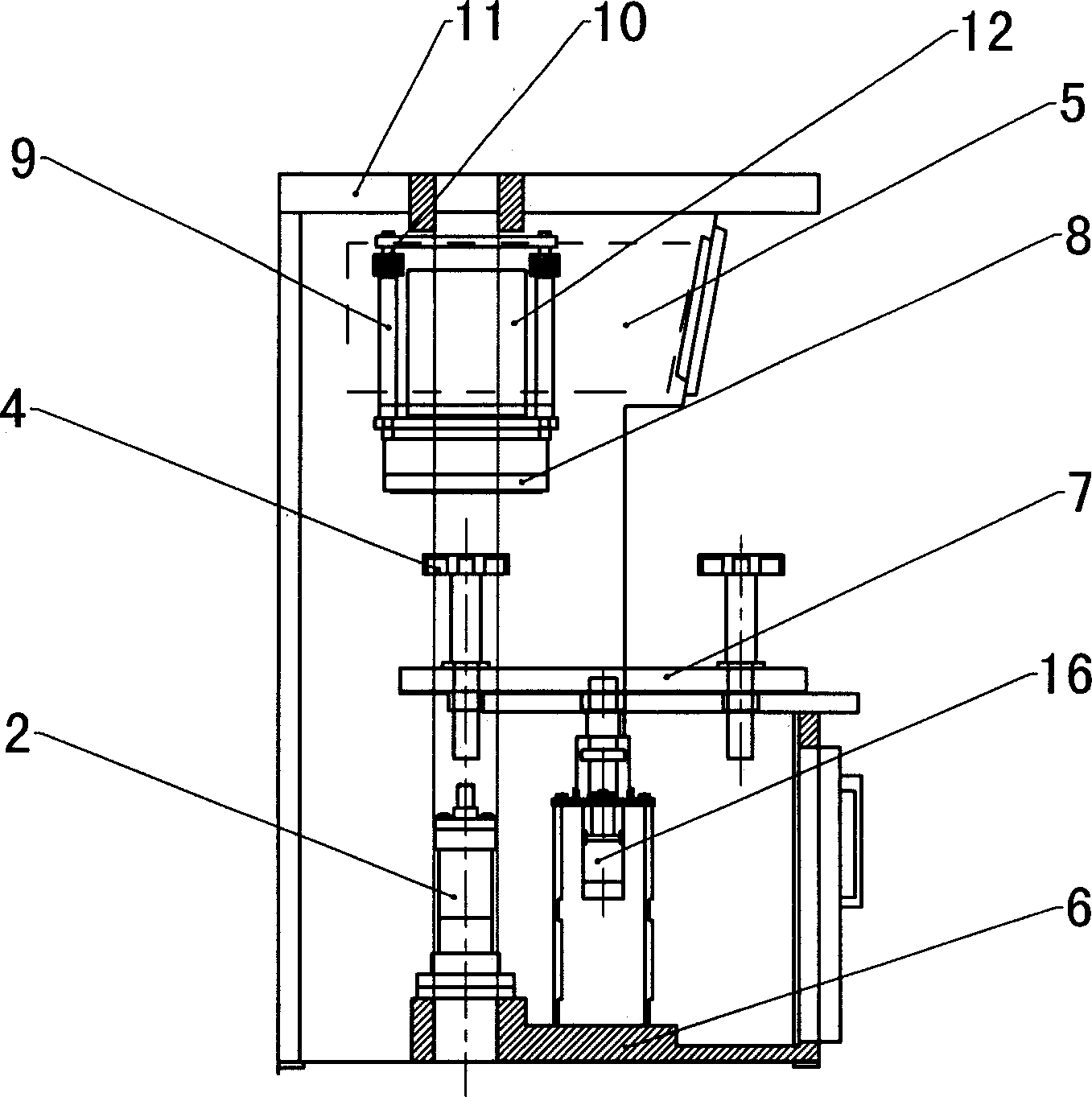

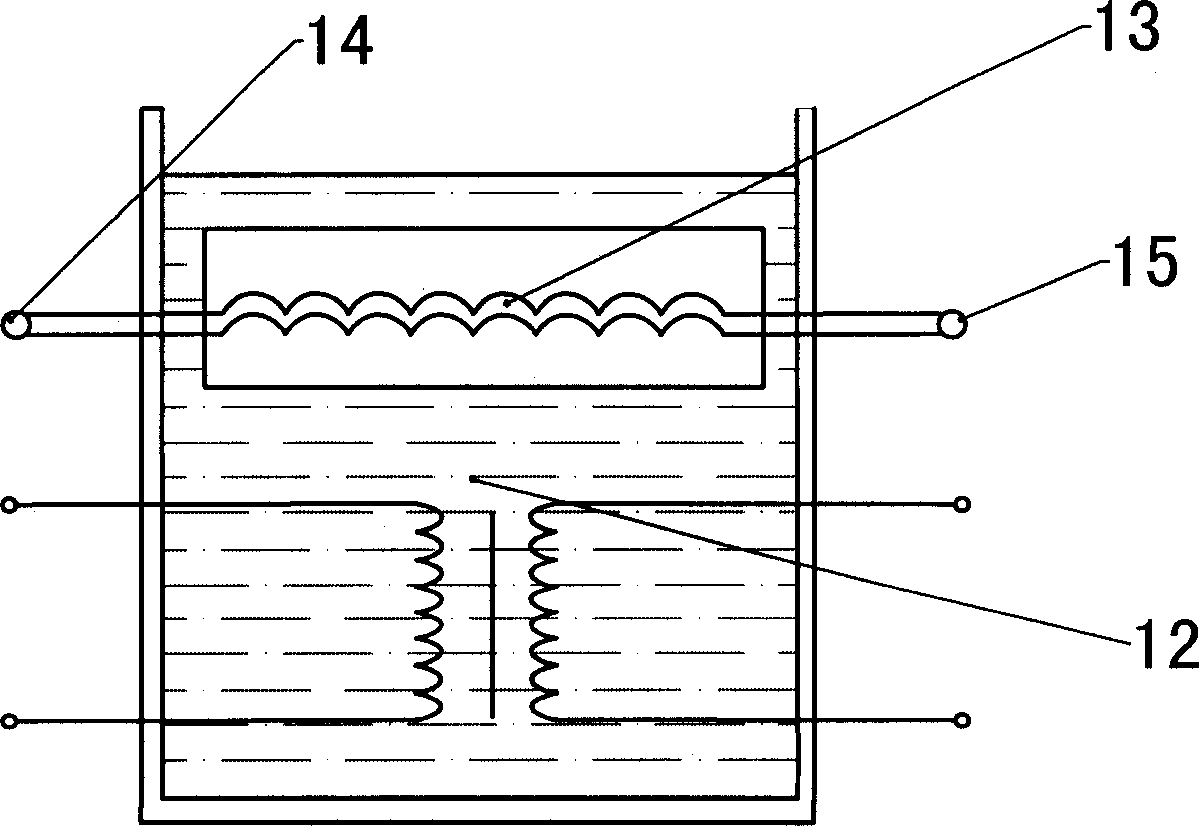

[0025] refer to Figure 1 to Figure 4, this embodiment is a microcomputer-controlled high-power all-solid medium and high-frequency induction heating brazing machine, including a frame 1, a pressure device 2, an upper die 3, a lower die 4, a heating device 5 and a microcomputer control device, and a pressure device 2 Installed on the machine base 6 of the frame 1, the lower mold 4 is installed on the rotating tray 7, the lower end of the upper mold 3 is provided with a heating die head 8, and the heating die head 8 is an elastic force balance device installed through the upper die connecting rod 9 10 is connected to the upper part 11 of the frame, and the elastic force is provided by the elastic force balance device, so that the heated workpiece is stressed and heated evenly; the heating device 5 is installed in the upper mold 3 on the upper side of the heating die head; the heating device 5 adopts a cooling oil-immersed transformer 12 , a cooler 13 is installed in the cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com