Cleaning and servicing technology for turbine blade basal body surface by strong current pulsed ionizing beam

A high-current pulse, turbine blade technology, used in blade support elements, engine elements, machines/engines, etc., can solve problems such as coating fracture failure, environmental pollution, and blade coating performance degradation, and achieve smooth and smooth processing surfaces. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

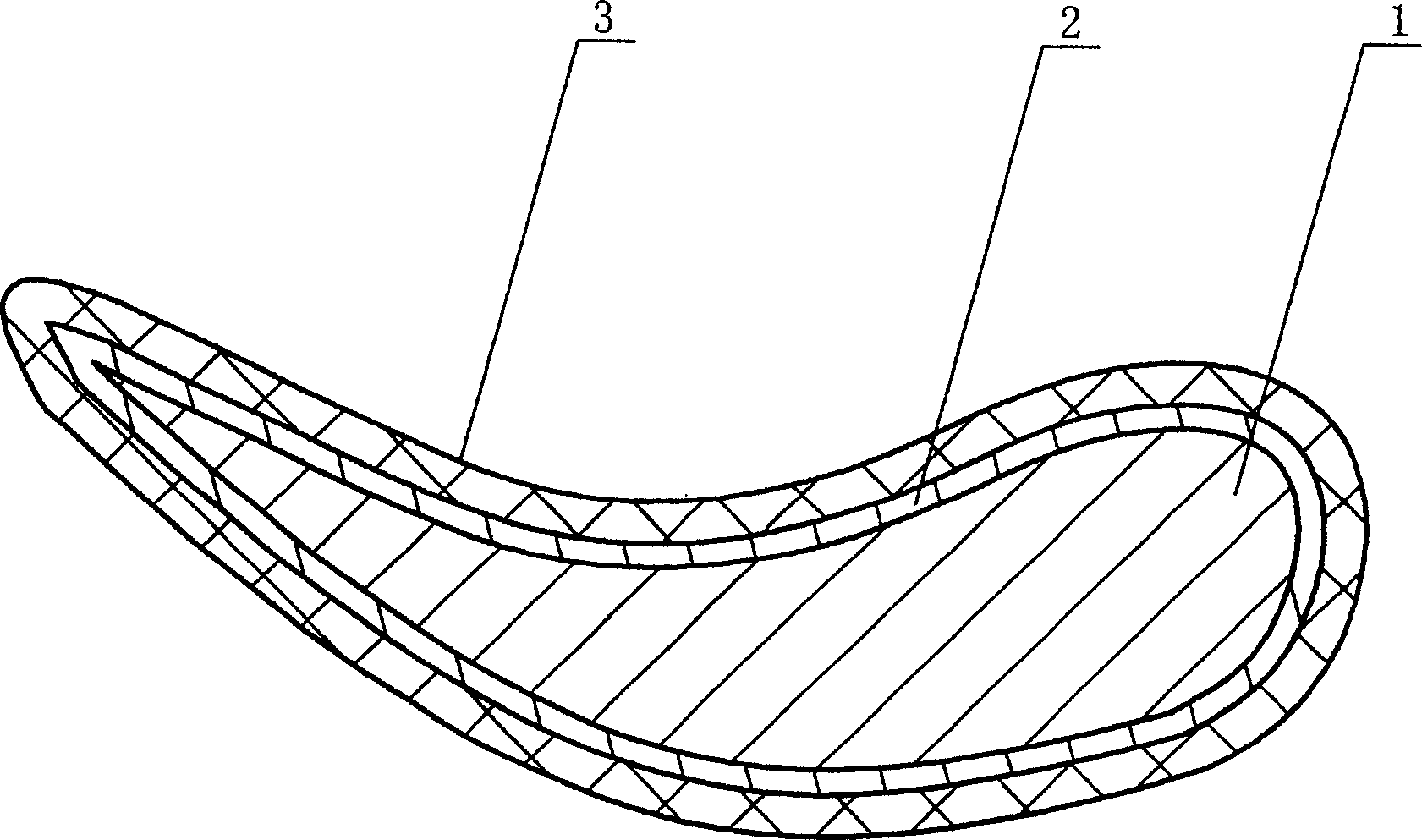

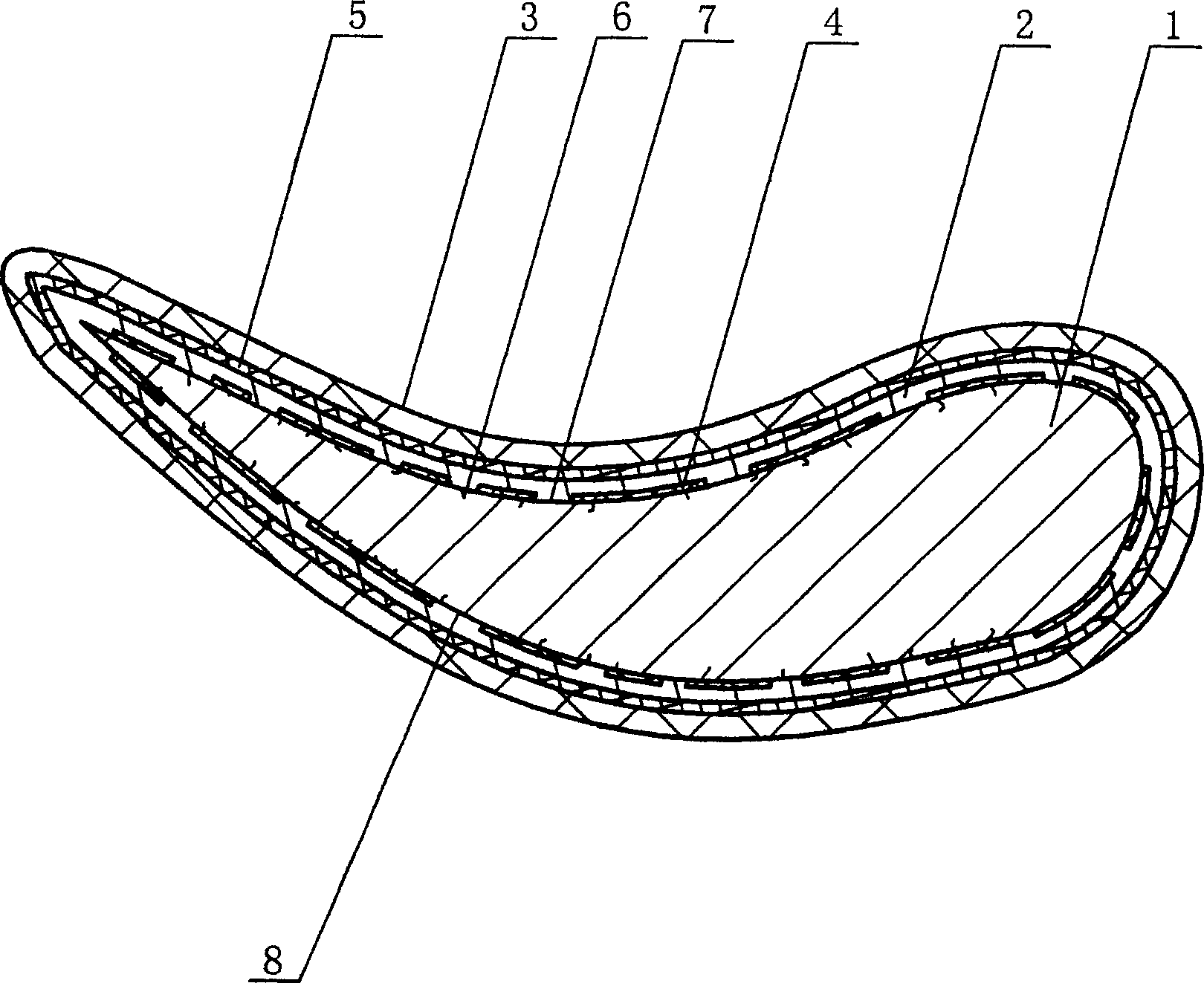

[0027] A company requires to clean the 0.1μm thick oxide [4] formed on the surface of the turbine blade matrix [1] that has been in service, and the removal thickness accuracy is required to reach ±0.02μm, and the blade processing surface is required to be smooth and the matrix does not produce deformation. The cleaning and maintenance technology for the surface of the turbine blade substrate with a high-current pulsed ion beam of the present invention has the following cleaning and maintenance process steps:

[0028] In the first step, place the blade with the ceramic heat-insulating top layer [3] and the metal bonded bottom layer [2] removed, and the oxide [5] formed therebetween, on the sample stage of the high-current pulsed ion beam device,

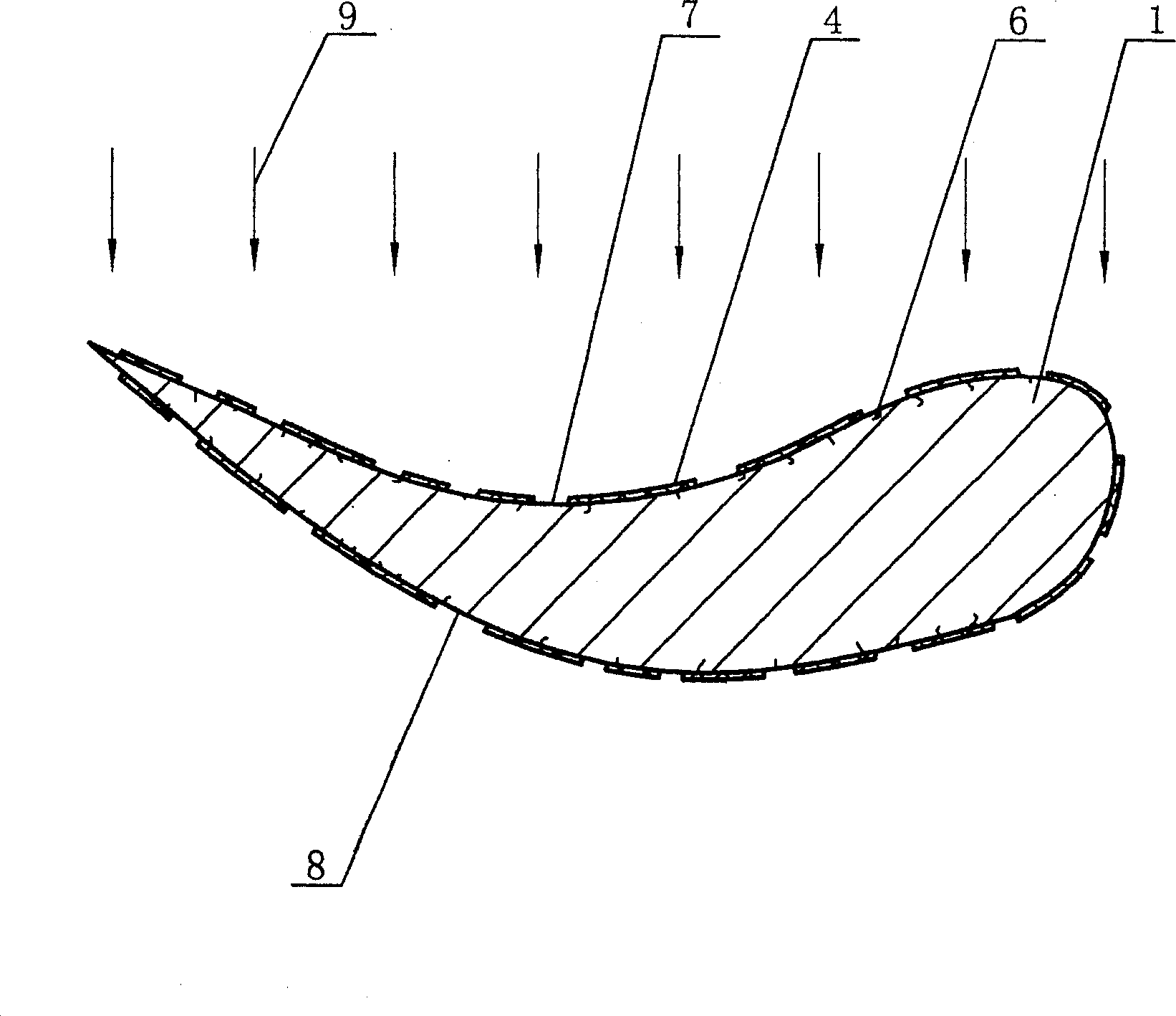

[0029] The blade is placed on the sample stage so that the front curved surface [7] of the blade is completely exposed to the beamline radiation area of the high-current pulsed ion beam [9], the vacuum chamber of the device is close...

Embodiment 2

[0039] An aero-engine company required to clean the 8.2 μm thick oxide [4] formed on the surface of the turbine blade matrix [1] that had been in service, and the removal thickness accuracy was required to reach ±0.1 μm, and the blade processing surface was required to be smooth and flat without deformation of the matrix. Now adopt the cleaning and maintenance technology of the present invention with the high-current pulsed ion beam to the surface of the turbine blade substrate, and its cleaning and maintenance process steps are as follows:

[0040] In the first step, place the blade with the ceramic heat-insulating top layer [3] and the metal bonded bottom layer [2] removed, and the oxide [5] formed therebetween, on the sample stage of the high-current pulsed ion beam device,

[0041] The blade is placed on the sample stage so that the front curved surface [7] of the blade is completely exposed to the beamline radiation area of the high-current pulsed ion beam [9], the vacuu...

Embodiment 3

[0051] A company requires to clean the 10μm thick oxide [4] formed on the surface of the turbine blade matrix [1] that has been in service. The removal thickness accuracy is required to reach ±0.1μm, and the blade processing surface is required to be smooth and flat without deformation of the matrix. Now this The cleaning and maintenance technology for the surface of the turbine blade substrate with the high-current pulsed ion beam invented, the cleaning and maintenance process steps are as follows:

[0052] In the first step, place the blade with the ceramic heat-insulating top layer [3] and the metal bonded bottom layer [2] removed, and the oxide [5] formed therebetween, on the sample stage of the high-current pulsed ion beam device,

[0053] The blade is placed on the sample stage so that the front curved surface [7] of the blade is completely exposed to the beamline radiation area of the high-current pulsed ion beam [9], the vacuum chamber of the device is closed and vacu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com