Lysostaphin industrial purifying process

A lysostaphin enzyme and process technology, which is applied in the field of enzyme purification process, can solve the problems of unsatisfactory yield and purity, weak rigidity of chromatography medium, and the flow rate of chromatography process cannot be too fast, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

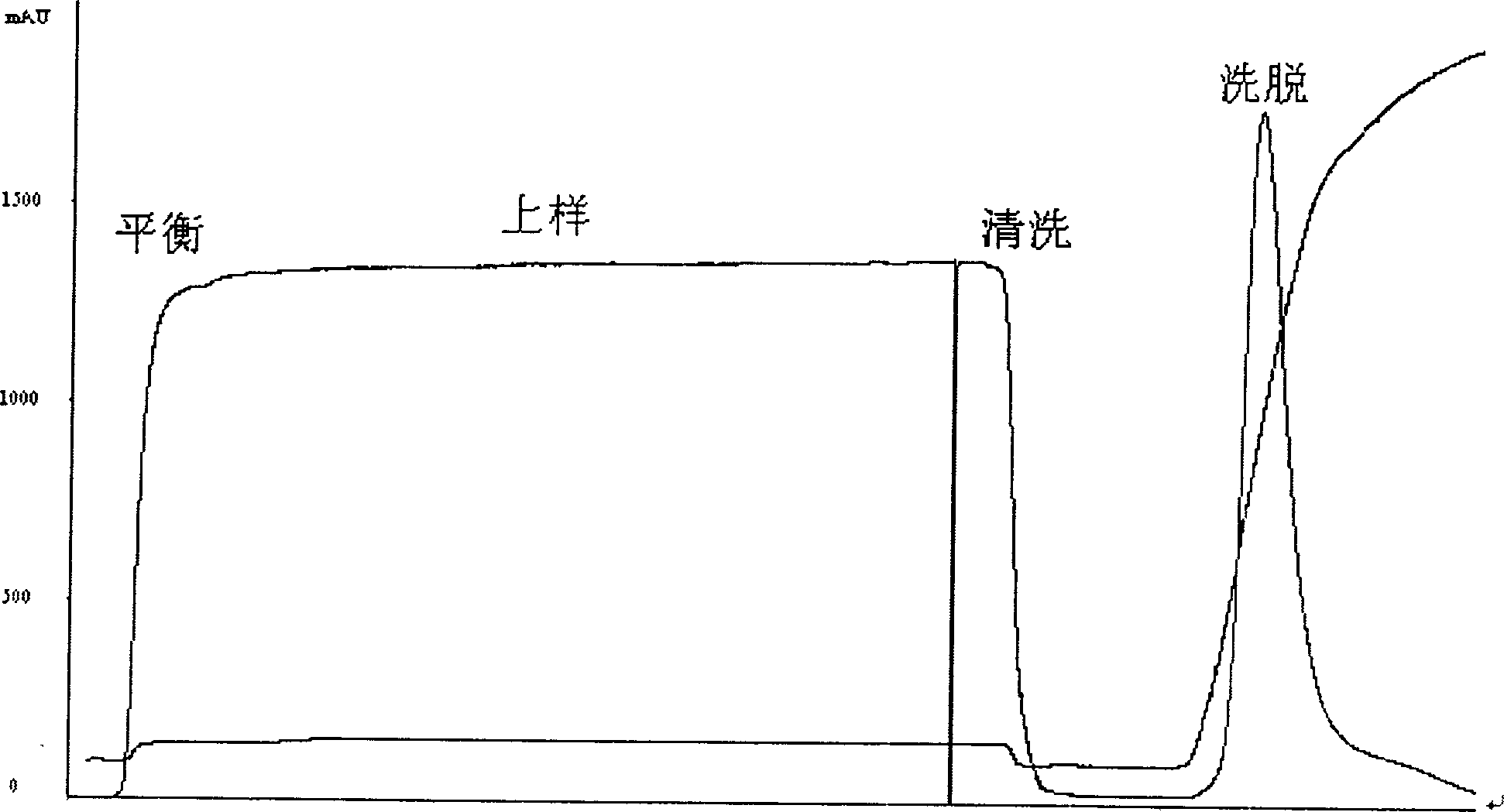

[0027] Ion exchange chromatography:

[0028] A chromatographic column containing 10 ml of strong cationic agarose gel (manufactured by Amersia Biotechnology Co., Ltd., trade name SP Sepharose BigBead (please provide specific standardized chemical name)) medium with a particle size of 100-300 μm, layer The diameter of the analysis column is 2.5 cm.

[0029] Sample: 200 ml culture supernatant of Bacillus sphaericus containing lysostaphin gene; containing 9750 units of lysostaphin.

[0030] Chromatography equipment: AKTA explorer 100 produced by Amersya Biotechnology Co., Ltd.;

[0031] Equilibrium and washing buffer: 15mmol / L phosphate buffer at pH6.5;

[0032] Elution buffer: 15mmol / L pH6.5 phosphate buffer containing 1mol / L NaCl.

[0033] Equilibration: Use 15mmol / L phosphate buffer solution with a pH of 6.5 to equilibrate the chromatographic column containing 10ml volume of SPSepharose BigBead medium, equilibrate 8 column volumes at a flow rate of 120cm per hour, and ensur...

Embodiment 2

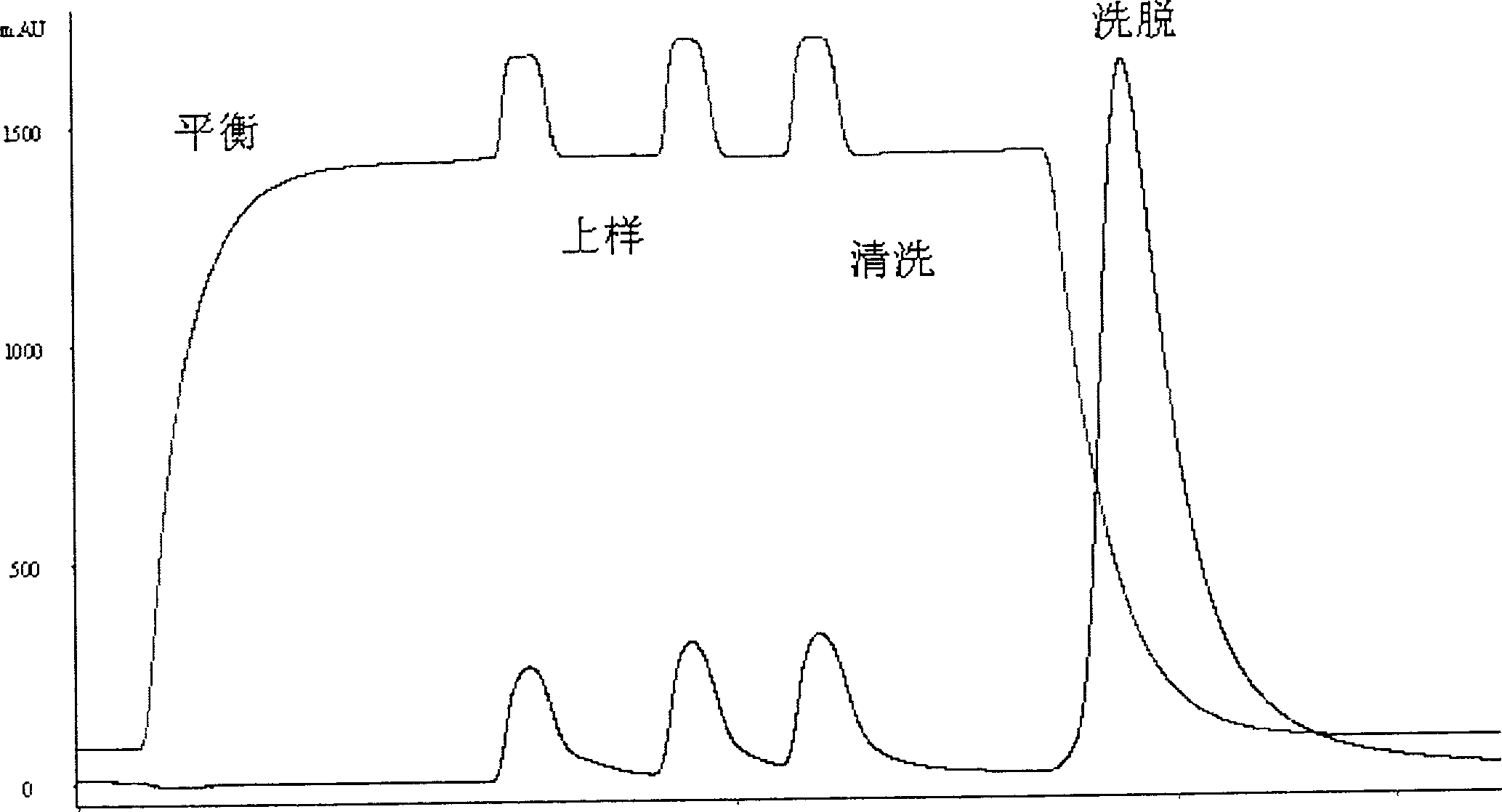

[0042] Hydrophobic chromatography

[0043] A chromatographic column with 1 ml of agarose gel (produced by Amersia Biotechnology Co., Ltd., trade name Phenyl Sepharose 6 fast flow) medium with a particle size of 20-165 μm and a phenyl group, the diameter of the chromatographic column is 0.6 cm.

[0044] Sample: Treat 10 ml of eluate from ion exchange chromatography; contains 8550 units of lysostaphin.

[0045] Chromatography equipment: AKTA explorer 100 produced by Amersya Biotechnology Co., Ltd.;

[0046] Equilibrium buffer: a phosphate buffer containing 1.5mol / L sodium chloride and 50mmol / L glycerol with a pH of 6.5;

[0047] Washing buffer: phosphate buffer containing 1.8mol / L sodium chloride and 50mmol / L glycerol with a pH of 6.5;

[0048] Elution buffer: phosphate buffer containing 50mmol / L glycerol and pH 6.5;

[0049] Equilibration: equilibrate the chromatography column with 1ml volume of Phenyl Sepharose 6 fast flow medium with equilibration buffer, equilibrate 5 co...

Embodiment 3

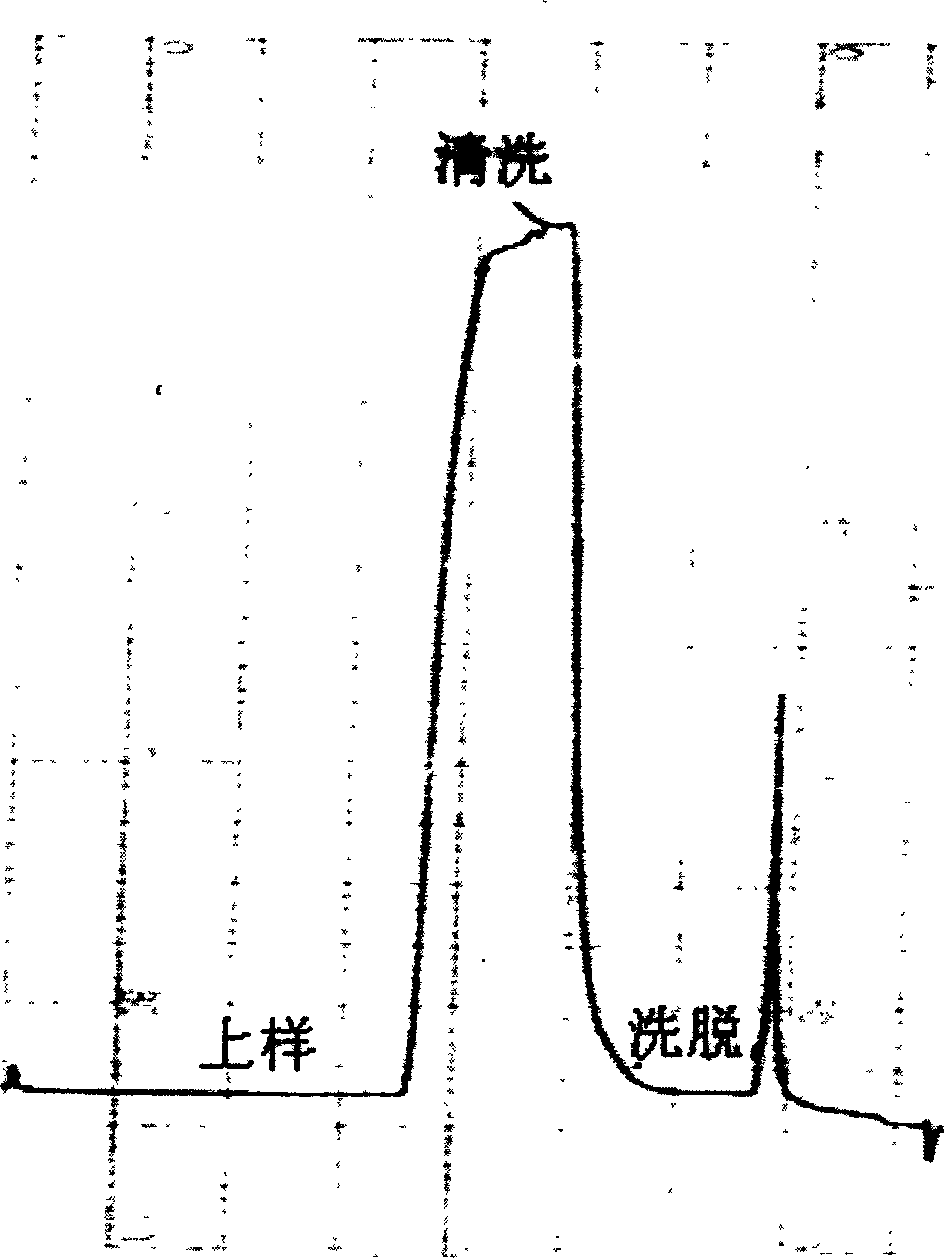

[0058] Ion exchange chromatography:

[0059] A chromatographic column with 3000ml of SP Sepharose BigBead medium is installed, and the diameter of the chromatographic column is 15 cm.

[0060] Sample: 45 liters of culture supernatant of Bacillus sphaericus containing lysostaphin gene; containing 4.95 million units of lysostaphin.

[0061] Chromatography equipment: 6mm Manual Process SystemTC from Amersya Biotechnology Co., Ltd.;

[0062] Equilibrium and washing buffer: 15mmol / L phosphate buffer at pH6.5;

[0063] Elution buffer: 15mmol / L pH6.5 phosphate buffer containing 1mol / L NaCl.

[0064] Balance: Use 15mmol / L pH 6.5 phosphate buffer to balance the chromatographic column equipped with 3000 ml volume of SP Sepharose BigBead medium, balance 6 column volumes at a flow rate of 120 cm per hour, and ensure that the chromatographic column is complete by ultraviolet detection. Equilibrate to baseline.

[0065] Sample pretreatment: Dilute 45 liters of sample (culture supernatan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com