Rowing with superfine fibre and its formation

A technology of super fiber and rowing boats, which is applied in the direction of warships, non-magnetic metal hulls, hulls, etc. It can solve the problems of reducing the rigidity of the hull, poor impact resistance of the hull, discounts on the service life of the rowing boat, etc., and improve the bonding strength. and impact toughness, avoiding high labor intensity and substantial rigidity of the hull

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

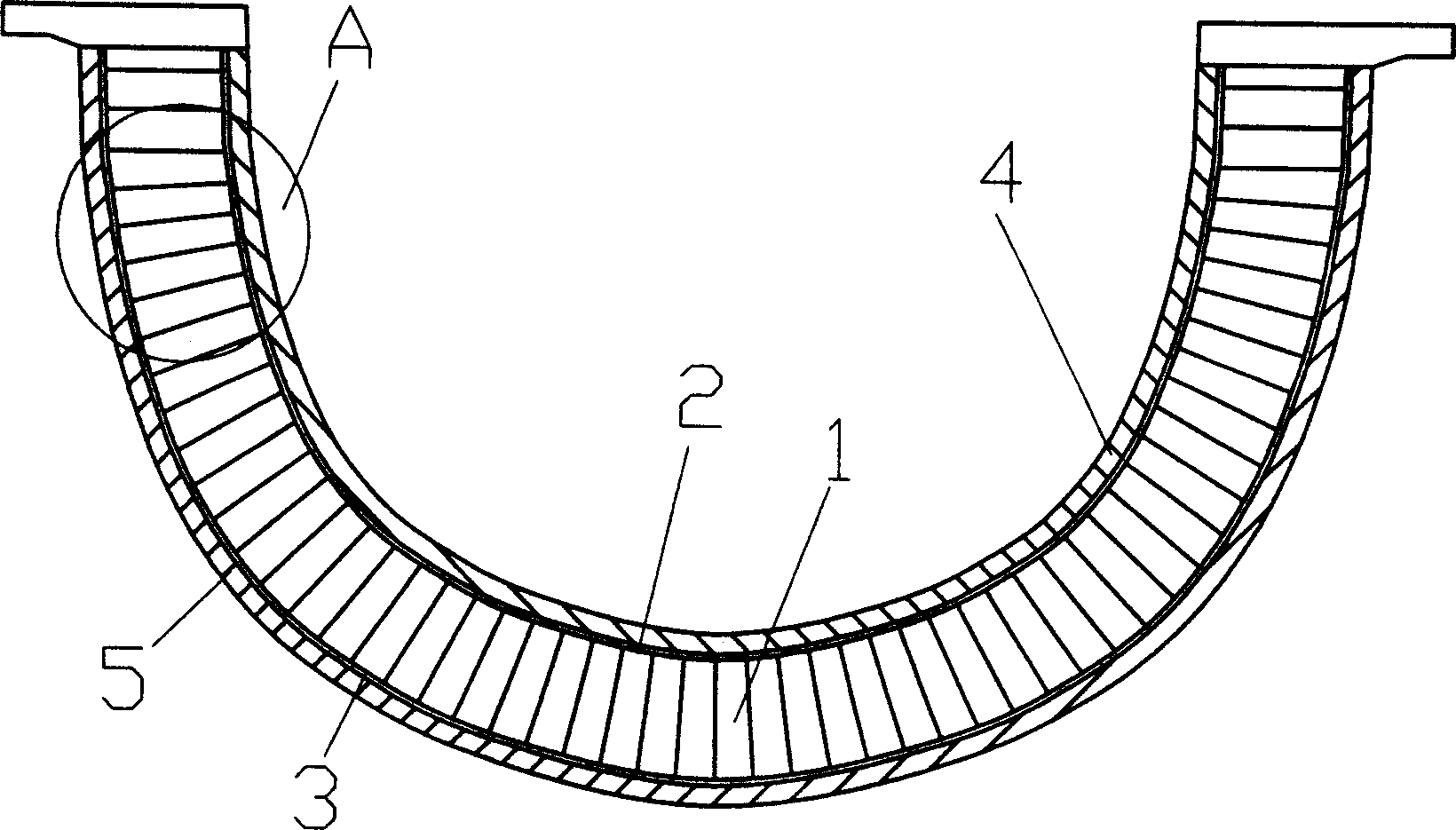

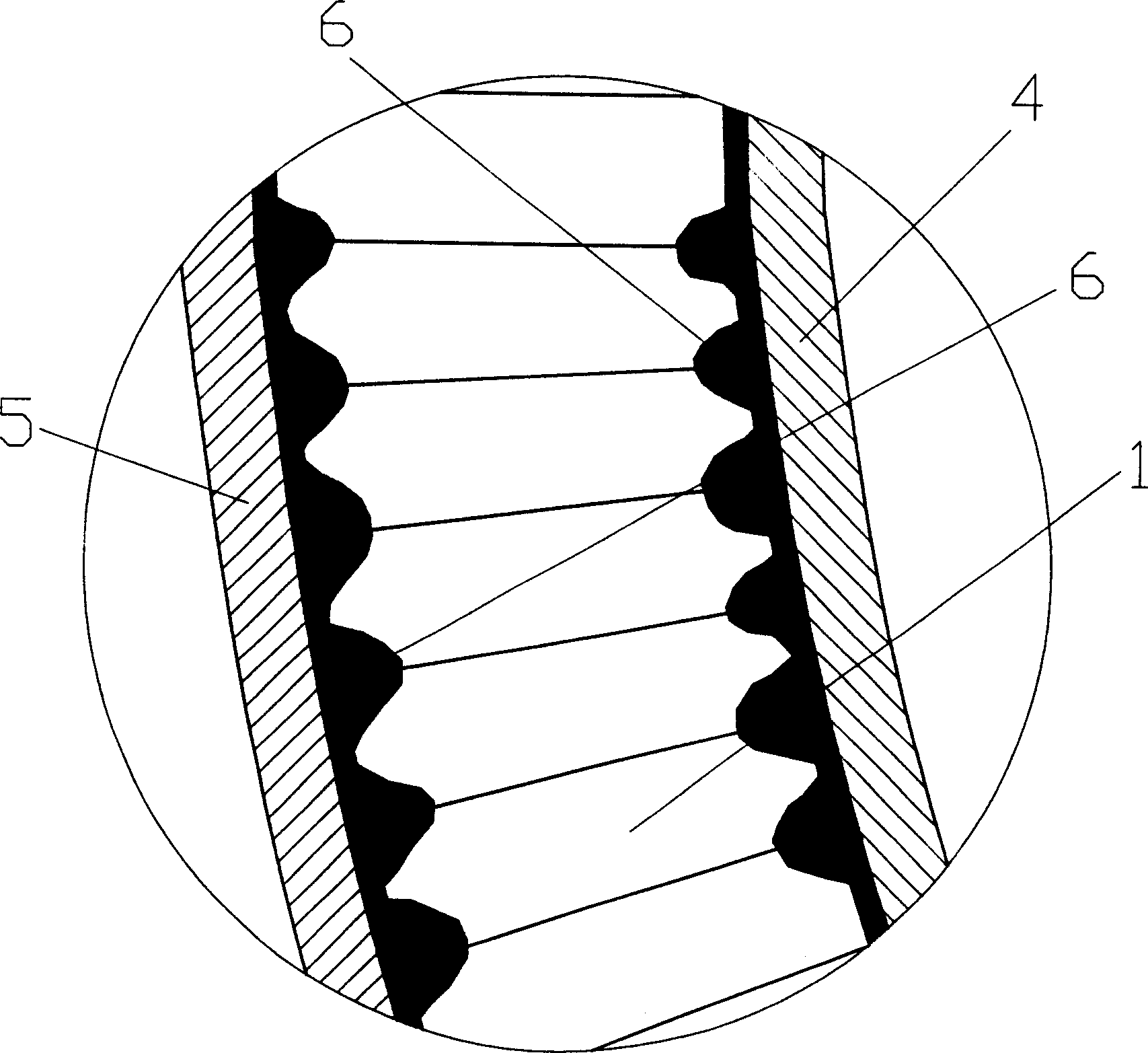

[0021] see figure 1 , the structure of the present invention is that the inner end face 2 and the outer end face 3 of the Nomex honeycomb sandwich core 1 are respectively bonded with an inner skin 4 and an outer skin 5, and the inner and outer skins are all made of special PBO super fiber prepreg, and the Nomex Glue bumps 6 are formed at the bonding parts of the honeycomb sandwich to improve the bonding strength and impact resistance toughness between the honeycomb sandwich and the skin.

[0022] The present invention adopts the dry molding process, which not only realizes relatively accurate calculation in design, but also can effectively control the quality of various raw materials in the process of blanking and molding construction, and then achieve the control of the standard quality of the final product; and in blanking, There is basically no pollution in the process of layer laying and curing. The overall structure of the rowing boat has been solidified into one piece, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com