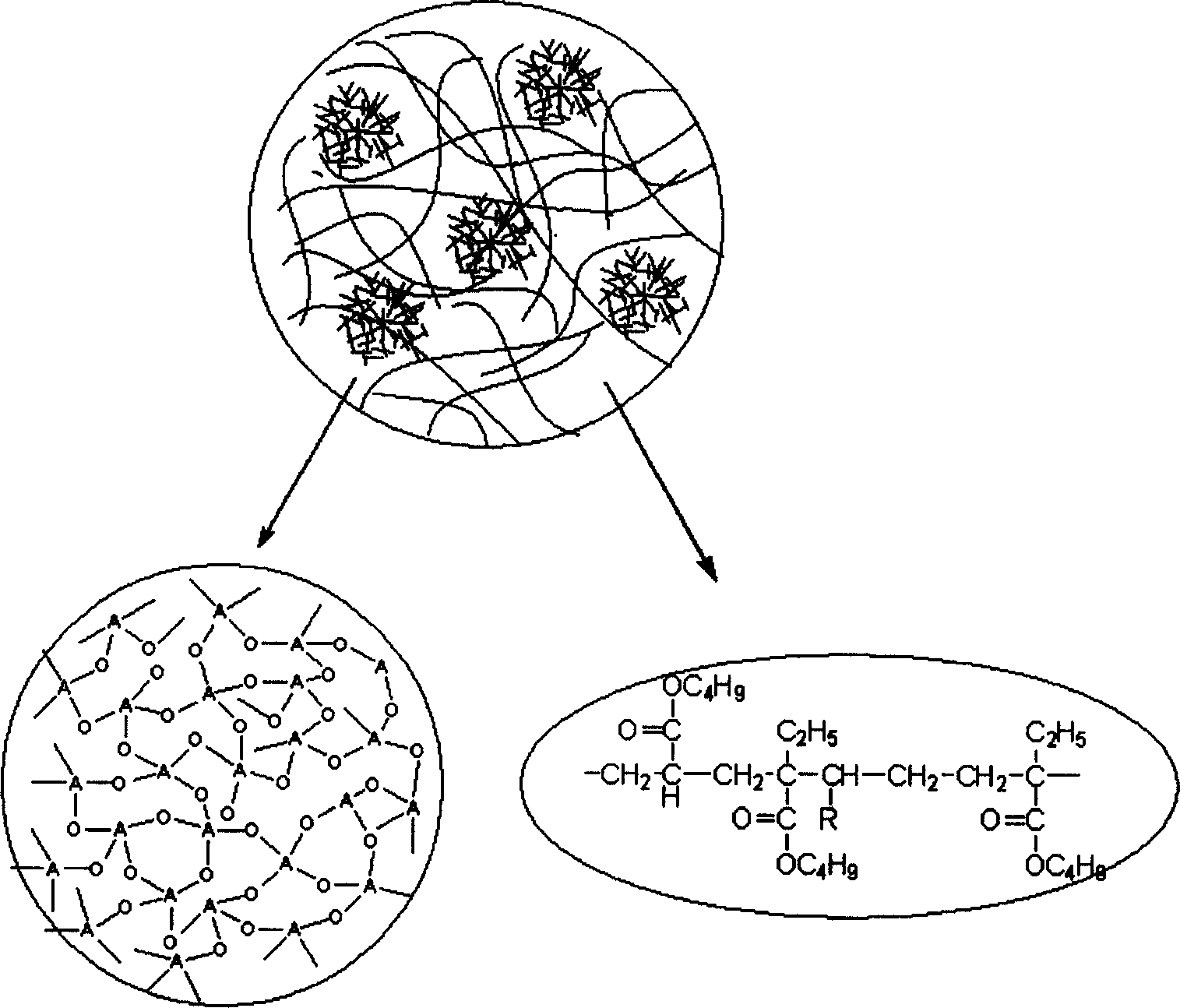

High-performance organic-inorganic resin coating material with hybrid acrylic ester and production thereof

An acrylate, coating material technology, applied in the direction of coating, devices for coating liquid on the surface, textiles and papermaking, etc., to achieve the effect of avoiding phase separation, good transparency and high gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Organic-inorganic hybrid acrylate resin coating material formula 1 is as follows:

[0029] Composition Weight (g)

[0030] 30% nano-titanium oxide sol 20

[0031] 30% nano-alumina sol 10

[0032] 50% carboxyacrylate resin 200

[0033] 30% alkoxy acrylate resin 20

[0034] Butyl acetate 20

[0035] Isophorone 5

[0036] Propylene glycol methyl ether acetate 3

[0037] Xylene 20

[0038] 200# solvent oil 2

[0039]In the dispersion kettle, add 20 grams of butyl acetate, 5 grams of isophorone, 3 grams of propylene glycol methyl ether acetate, 20 grams of xylene, 2 grams of 200# solvent oil, and 200 grams of carboxyl acrylate resin with a solid content of 50%. , 20 grams of alkoxy acrylate resins with a solid content of 30%, slowly add 20 grams of 30% nano-titanium oxide sol, 10 grams of 30% nano-alumina sol at a speed of 500 rpm, add in 30 minutes, and continue to stir for 20 minutes The organic-inorganic hybrid acrylate coating material can be prepared in minutes...

Embodiment 2

[0042] Organic-inorganic hybrid acrylate resin coating material formulation 2 is as follows:

[0043] Composition Weight (g)

[0044] 50% nano silica sol 170

[0045] 80% hydroxy acrylate resin 120

[0046] 50% polyurethane resin 10

[0047] Dispersant 0.5

[0048] Wetting agent 0.6

[0049] Leveling agent 0.2

[0050] In the dispersion kettle, add 120 grams of hydroxyacrylate resin with a solid content of 80%, 10 grams of 50% polyurethane resin, 0.5 grams of dispersant, 0.6 grams of wetting agent, 0.2 grams of leveling agent, and slowly add 170 grams of it at 1000 rpm Add 50% nano-silica sol within 60 minutes and continue to stir for 30 minutes to prepare the organic-inorganic hybrid acrylate coating material. The coating film is cured at 70°C for 1 hour to obtain an organic-inorganic hybrid Acrylic resin coating.

[0051] The nano-oxide content in the coating is 28wt%, the gloss (Gloss 20°) is 96, the pencil hardness is 5H, the flexibility is 1mm, the impact strength ...

Embodiment 3

[0053] Organic-inorganic hybrid acrylate resin coating material formulation 3 is as follows:

[0054] Composition Weight (g)

[0055] 30% nano silica sol 50

[0056] 30% nano zirconia sol 20

[0057] 30% nano-alumina sol 10

[0058] 40% epoxy acrylate resin 20

[0059] 40% hydroxy acrylate resin 100

[0060] Acetone 45

[0061] Butyl acetate 25

[0062] Isopropanol 5

[0063] Titanium dioxide 12

[0064] Aluminum powder 10

[0065] Aluminum powder directional agent 2

[0066] Dispersant 0.1

[0067] Defoamer 0.2

[0068] Anti-settling agent 0.3

[0069] In the dispersion kettle, add 25 grams of acetone, 25 grams of butyl acetate, 5 grams of isopropanol, 12 grams of titanium dioxide, 10 grams of aluminum powder, 2 grams of aluminum powder orientation agent, 0.1 grams of dispersant, 0.2 grams of defoamer, 0.3 gram of anti-settling agent, stirred at a high speed at 2000rpm for 30 minutes, then added 20 grams of epoxy acrylate resin with a solid content of 40%, and 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pencil hardness | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

| Pencil hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com