Boitrickling filter deodourization system of sewage chemical off odour and its deodour method

A biological trickling filtration and deodorization technology is applied in the biological treatment system of chemical odor and in the field of sewage, which can solve the problems of device packing blockage, low treatment efficiency, and large device volume, and achieves the effects of low cost, simple process and small volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

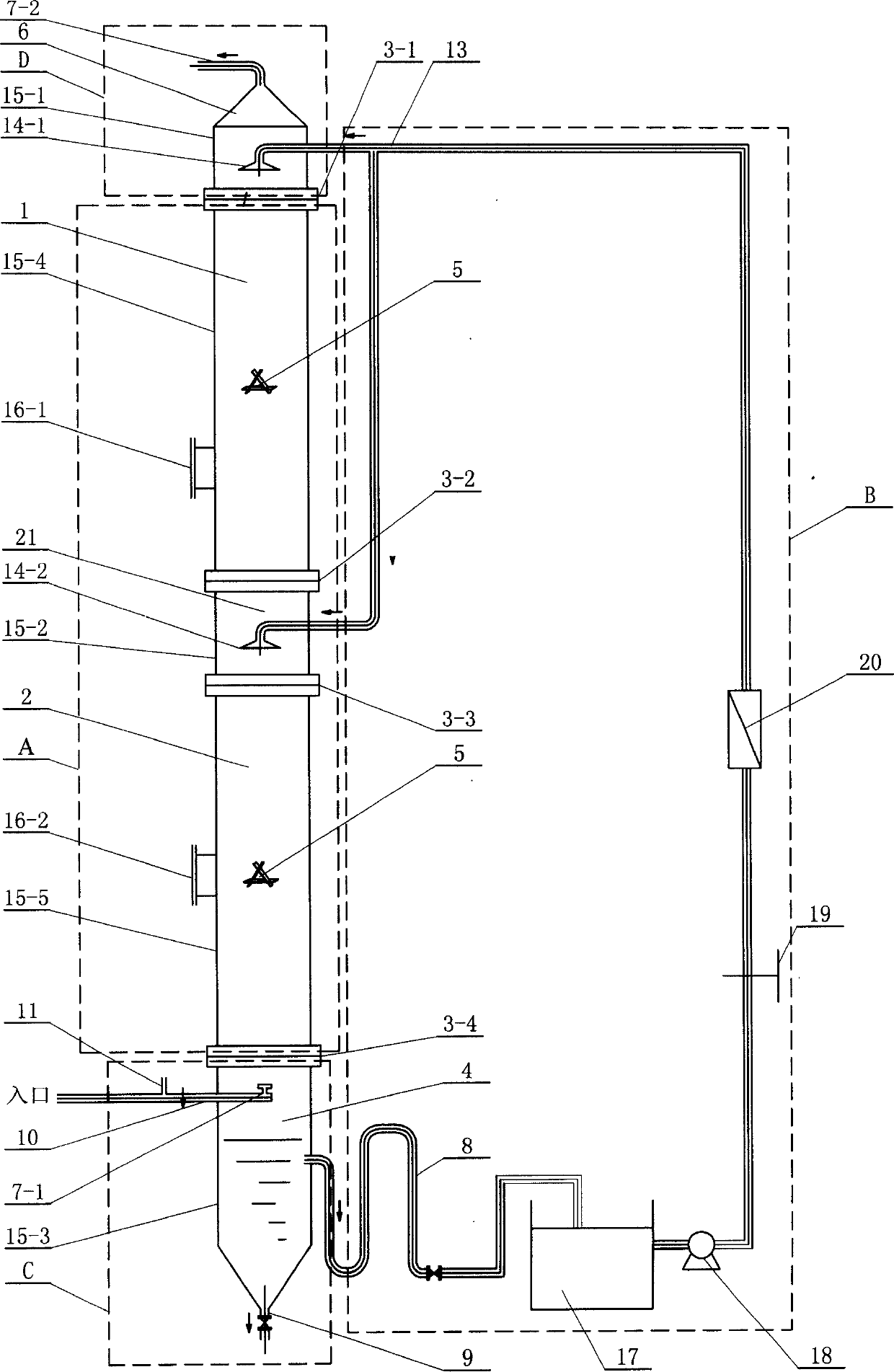

[0012] Specific embodiment one: the deodorization system of this embodiment is made up of biological dripping filtration deodorization reaction device A, water circulation device B, gas input and discharge device C, gas output device D, the lower end of biological trickle filtration deodorization reaction device A and gas input It is connected with the upper end of the discharge device C, the upper end of the biological trickling filter deodorization reaction device A is connected with the lower end of the gas output device D, the upper end of the water circulation device B is connected with the inside of the gas output device D, and the middle part of the water circulation device B is connected with the biological trickling filter. The middle part of the deodorization reaction device A is connected, and the lower end of the water circulation device B is connected with the middle part of the gas input and discharge device C. The bio-trickling deodorization reaction device A inc...

specific Embodiment approach 2

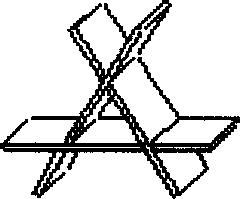

[0013] Specific embodiment two: the biological trickle filtration deodorization reaction device A of the present embodiment is made up of upper reactor 1, lower reactor 2, spray tank 21, isolation layer 3, filler 5, pipe wall 15-2, sampling port 16, The upper reactor 1 has a built-in filler 5, which is made of glass fiber reinforced plastic with a cross-flow structure, each piece is 30-40mm long, 10-15mm wide, and 0.4-0.8mm thick, and the specific surface area of the filler is 225m 2 / m 3 , the filler 5 has a rough surface, is easy to hang a film, and has a large specific surface area, which can avoid short flow and blockage. The lower part is connected, an upper isolation layer 3-1 is fixed in the middle of the connection between the upper reactor 1 and the gas collector 6, and the upper reactor 1 and the lower reactor 2 are connected by a spray barrel 21, and the lower part of the upper reactor 1 is connected to the gas collector 6. The upper part of the pipe wall 15-2 of...

specific Embodiment approach 3

[0014] Specific embodiment three: the water circulation device B of this embodiment is composed of an upper shower 14-1, a lower shower 14-2, a U-shaped drain pipe 8, a water tank 17, a circulating pump 18, a gate valve 19, and a flow meter 20. On the pipe wall 15-3 of the gas input and discharge system C, there is a hole connected to one end of the U-shaped drain pipe 8, the other end of the U-shaped drain pipe 8 is connected to the input end of the circulating water tank 17, and the output of the circulating water tank 17 The end is connected to the input end of the circulation pump 18, the output end of the circulation pump 18 is connected to one end of the gate valve 19, the other end of the gate valve 19 is connected to the input end of the flowmeter 20, the output end of the flowmeter 20 is connected to one end of the water pipe 13, The other end of the water pipe 13 is connected with the inlets of the upper shower 14-1 and the lower shower 14-2. The other components and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com