ZSM-23/ZSM-22 composite molecular sieve and its preparation method

A composite molecular sieve, ZSM-23 technology, applied in molecular sieves and alkali exchange compounds, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as ineffectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

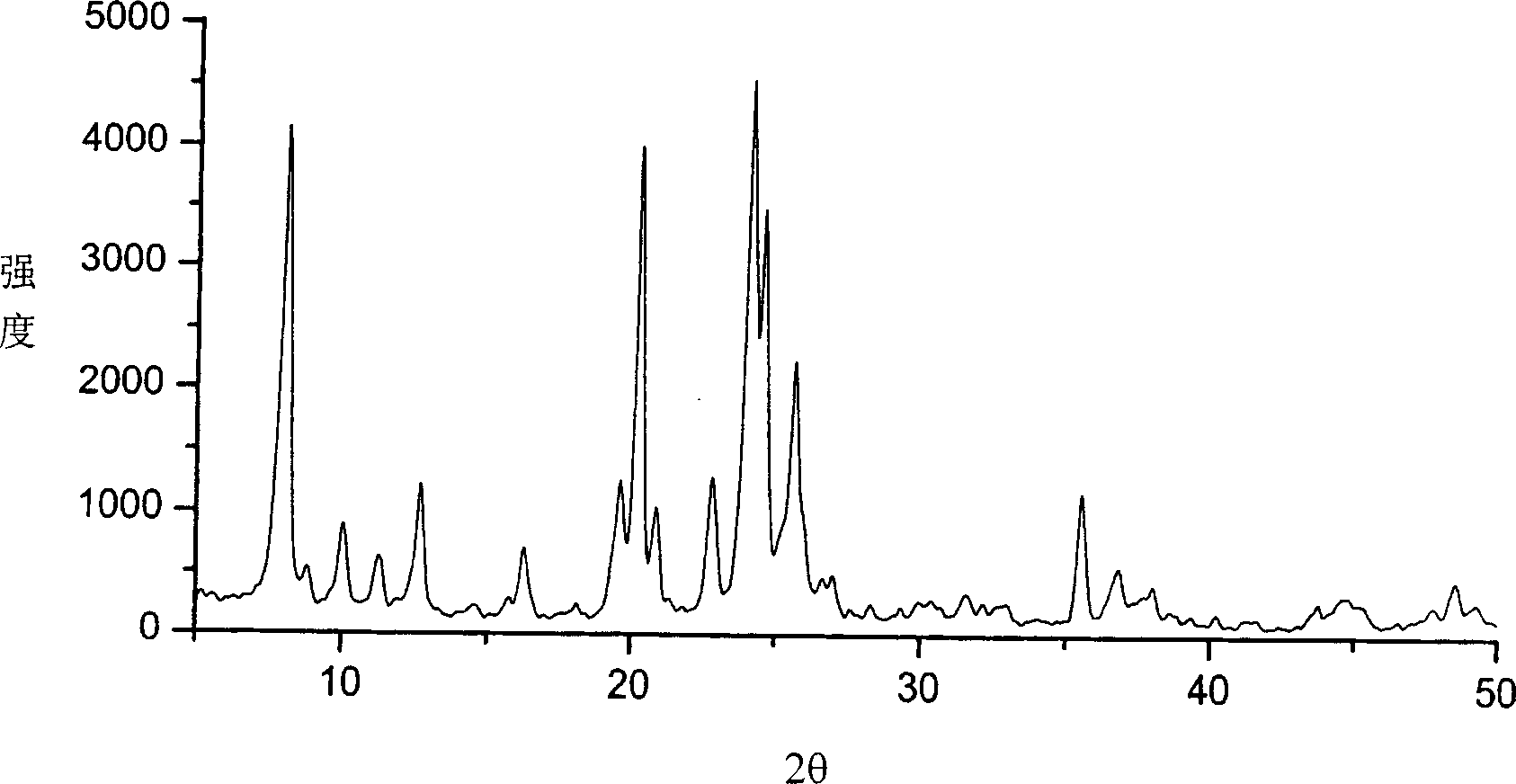

Image

Examples

Embodiment 1

[0034] 13.2 grams of sodium hydroxide was dissolved in 662 grams of water, 176.2 grams of silica sol (30% silicon dioxide) was added thereto, stirred for 5 hours, 15.0 grams of sodium ZSM-23 molecular sieve was added, and A was obtained after uniform stirring. 57.6 gram of diethylamine, add in the solution of 5.4 gram of aluminum sulfate and 244 gram of water, obtain B after stirring. Add B to A, stir vigorously for 24 hours, adjust the acidity and alkalinity of the system with 15.1 g of 98% concentrated sulfuric acid, and then continue vigorously stirring for 12 hours to obtain the initial colloid. The molar composition of the initial colloid is: SiO 2 / Al 2 o 3 = 108.6, R / SiO2 =0.9,OH - / SiO 2 =0.08, Na / SiO 2 =0.4,H 2 O / SiO 2 =65, the addition of ZSM-23 molecular sieve is 0.28 of the silica weight. Transfer the initial colloid to a 2-liter stainless steel autoclave lined with a polytetrafluoroethylene cup, put it into a rotating oven, adjust the rotation speed to 30 ...

Embodiment 2

[0036] Dissolve 13.2 grams of sodium hydroxide in 520 grams of water, add 5.0 grams of sodium ZSM-23 molecular sieve, stir for 0.5 hour, add 176.2 grams of silica sol (30% silicon dioxide), and stir to obtain A. 57.6 grams of diethylamine are added to the solution of 2.7 grams of aluminum sulfate and 244 grams of water, and B is obtained after stirring. Add B to A, stir vigorously for 24 hours, adjust the acidity and alkalinity of the system with 15.1 g of 98% concentrated sulfuric acid, and then continue vigorously stirring for 12 hours to obtain the initial colloid. The molar composition of the initial colloid is: SiO 2 / Al 2 o 3 =217, R / SiO 2 =0.9,OH - / SiO 2 =0.08, Na / SiO 2 =0.4,H 2 O / SiO 2 =56, the addition of ZSM-23 molecular sieve is 0.09 of the silica weight. Transfer the initial colloid to a 2-liter stainless steel autoclave lined with a polytetrafluoroethylene cup, put it into a rotating oven, adjust the rotation speed to 30 rpm, raise the temperature to 160...

Embodiment 3

[0038] 13.2 grams of sodium hydroxide were dissolved in 520 grams of water, 176.2 grams of silica sol (30% silicon dioxide) was added thereto, stirred for 5 hours, 15.0 grams of sodium ZSM-23 molecular sieves were added, and A was obtained after uniform stirring. 85 grams of diethyltriamine are added to the solution of 5.4 grams of aluminum sulfate and 244 grams of water, and B is obtained after stirring. Add B to A, stir vigorously for 24 hours, adjust the acidity and alkalinity of the system with 15.1 g of 98% concentrated sulfuric acid, and then continue vigorously stirring for 12 hours to obtain the initial colloid. The molar composition of the initial colloid is: SiO 2 / Al 2 o 3 = 108.6, R / SiO 2 =0.9,OH - / SiO 2 =0.08, Na / SiO 2 =0.4,H 2 O / SiO 2 =56, the addition of ZSM-23 molecular sieve is 0.28 of the silica weight. Transfer the initial colloid to a 2-liter stainless steel autoclave lined with a polytetrafluoroethylene cup, put it into a rotating oven, adjust th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com