Biological trickling filter bed for treating odorant pollutant in air

A biological trickling filter bed, pollutant technology, applied in the direction of air quality improvement, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of increased operating costs, decreased removal rate, increased pressure drop, etc., to reduce investment and operation. cost, the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Experimental conditions

[0030] Laboratory test

[0031] Gas composition: hydrogen sulfide + air

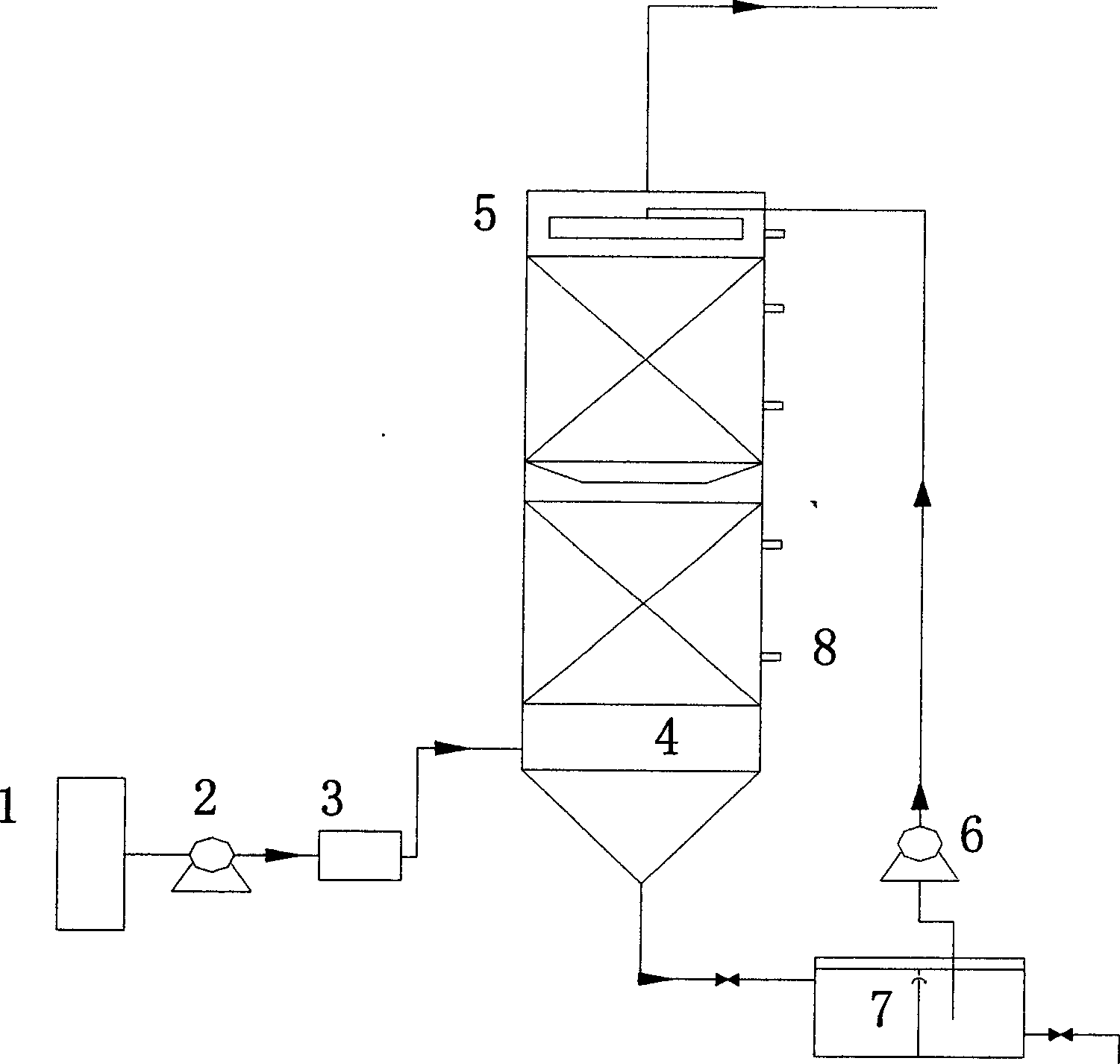

[0032] Reactor: The inner diameter of the packed tower is 150 mm, made of transparent plexiglass. The total height of the packing layer is 600mm, divided into two layers, each layer is 300mm in height, and the layer spacing is 100mm. Aspect ratio: 4

[0033]Filler: see Table 1, the filling volume is 10L, including 5L of large particle filler and 5L of small particle filler.

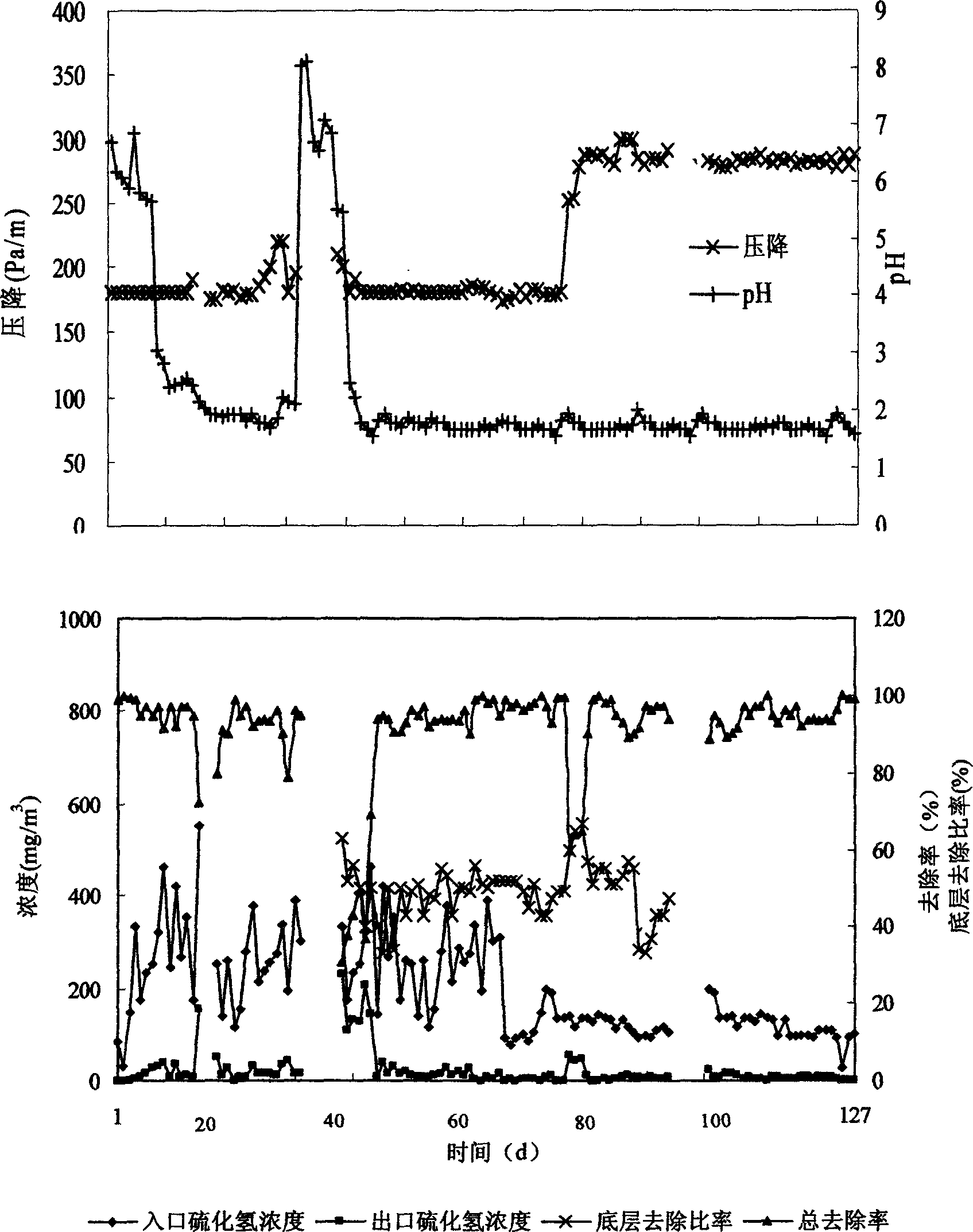

[0034] 2. See the attached figure 2 , Biological inoculation of Thiobacillus or mixed species including Thiobacillus.

Embodiment 2

[0036] 1. Experimental conditions

[0037] Actual malodorous gas treatment in sewage lifting pumping station

[0038] Gas composition: actual malodorous gas

[0039] Reactor: The inner diameter of the packed tower is 1500mm, reinforced concrete structure. The total height of the packing layer is 3500mm, divided into two layers, each layer is 1600mm, and the layer spacing is 300mm.

[0040] It is also possible to fill the bottom of each layer with large particle fillers and the top with small particle fillers. The size of the particle packing in the lower layer is correspondingly larger than the size of the particle packing in the upper tower.

[0041] Packing: See Table 1, filling volume is 5.6m 3 Among them, the large particle and small particle filler are each 2.8m 3 .

[0042] 2. Operation effect:

[0043] Biological inoculation of Thiobacillus or mixed species including Thiobacillus. The entire continuous operation time is 180 days, and the peak concentration of hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com