Prepn of submicron/micron micro lens array on polymer surface

A microlens array, polymer technology, applied in the application, home appliances, other home appliances and other directions, can solve the problems of long production cycle, cost reduction, complex equipment, etc., and achieve low cost, low equipment requirements, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

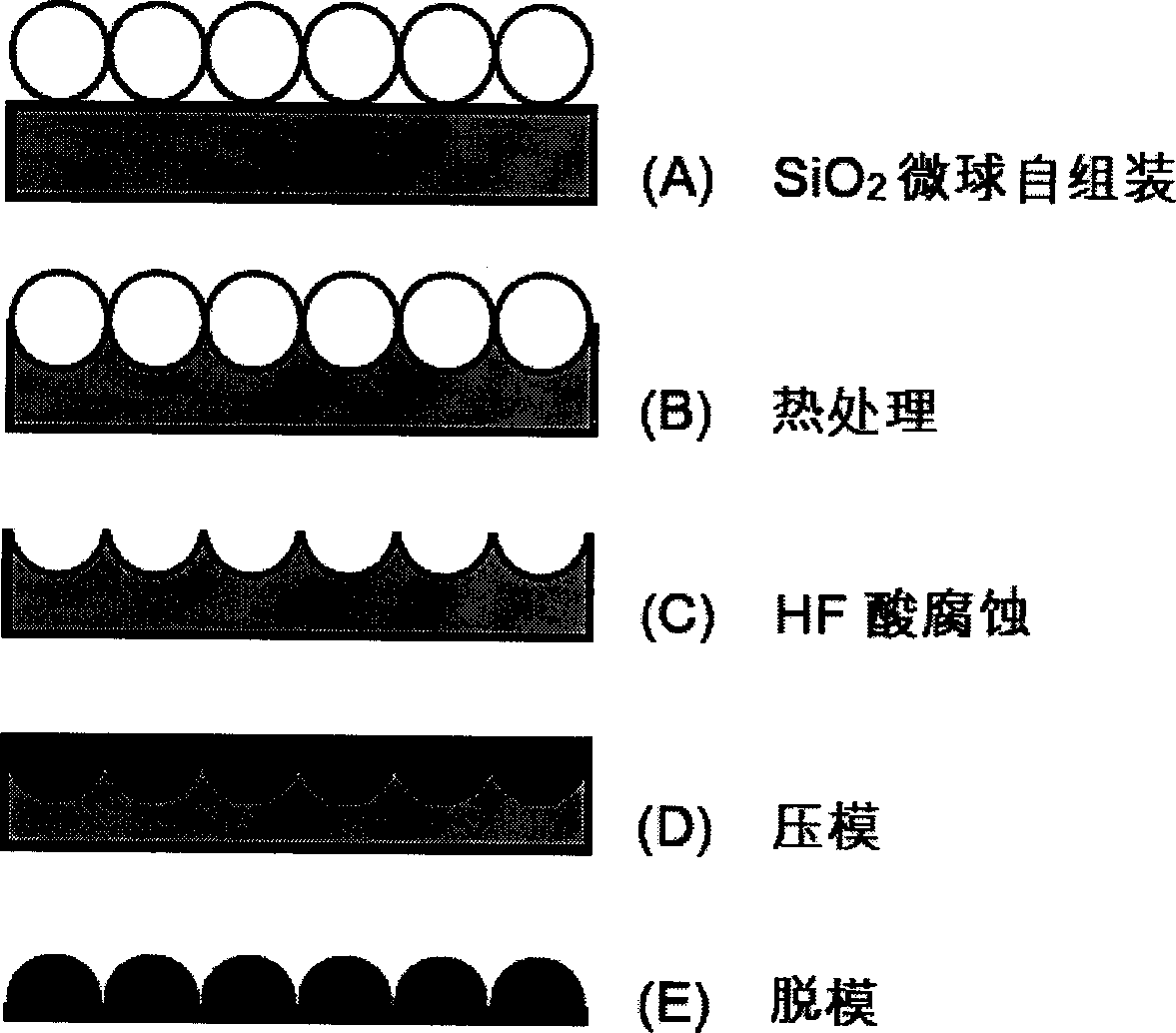

[0018] Example 1: Arranging submicron / micron SiO on the surface of polycarbonate polymer with high softening point and low elasticity by self-assembly technology 2 Microspheres, to obtain a large-area highly ordered two-dimensional single-layer microsphere array; then put it in an incubator for heat treatment at 140 ° C for 1 min; use HF acid solution to remove SiO 2 After microspheres, a large-area highly ordered two-dimensional concave lens array on the surface of polycarbonate and other polymers can be obtained; the above-mentioned concave lens array is used as a template to press on the surface of polymethyl methacrylate polymer with high light transmittance, and put Heat treatment at 80°C for 5 minutes in an incubator and demoulding to obtain a convex lens array on the surface of polymers such as polymethyl methacrylate or polystyrene;

Embodiment 2

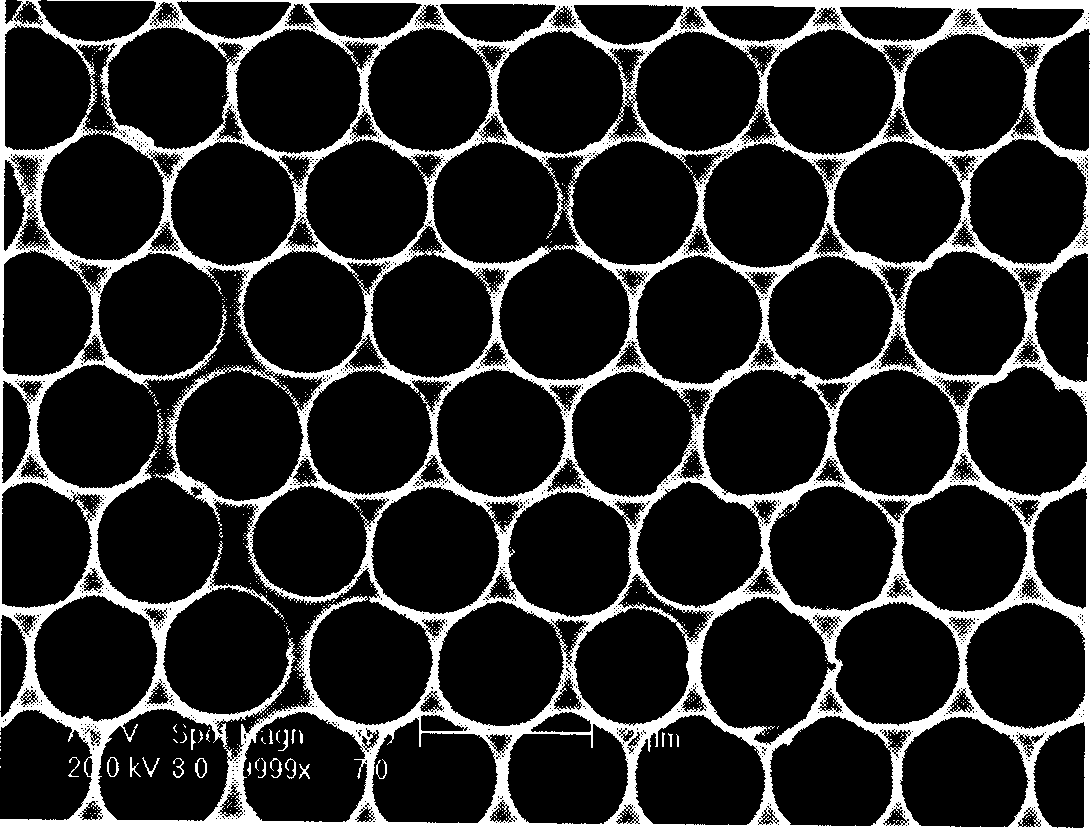

[0019] Embodiment 2: utilize self-assembly technology to SiO 2 The microspheres were arranged on the surface of polycarbonate, and then heat-treated at 180 °C for 24 h, and after natural cooling, the SiO 2 The template is removed to obtain a polycarbonate dimple lens array, see figure 2 .

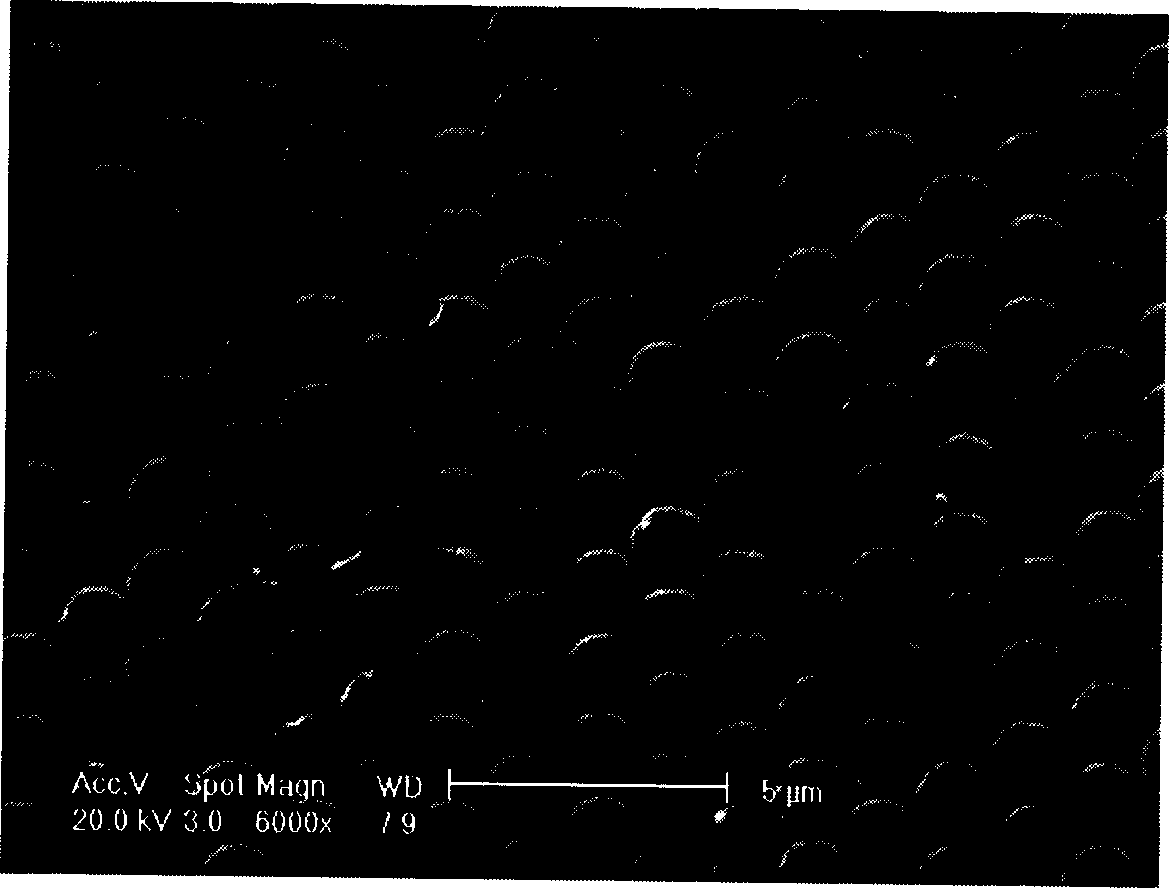

[0020] Place the above-mentioned micro-convex lens as a stamp on the surface of polymethyl methacrylate film, treat it at 130°C for 1 hour, and obtain a polymethyl methacrylate micro-convex lens array after demoulding, see image 3 .

Embodiment 3

[0021] Embodiment 3: the preparation process is the same as the embodiment, the difference is that the high softening point and low elasticity polymer is selected polyamide (or polyoxymethylene), and another polymer material with high light transmittance is polystyrene, the first heat treatment The temperature is 150°C, and the time is 10h; the second heat treatment temperature is 100°C, and the time is 30min. The result is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com