Method for preparing ferrous lithium phosphate

A lithium iron phosphate, lithium source technology, applied in chemical instruments and methods, phosphorus compounds, structural parts, etc., can solve the problems of high cost of raw materials, complicated processes, etc., and achieve a simple preparation process, easy doping, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

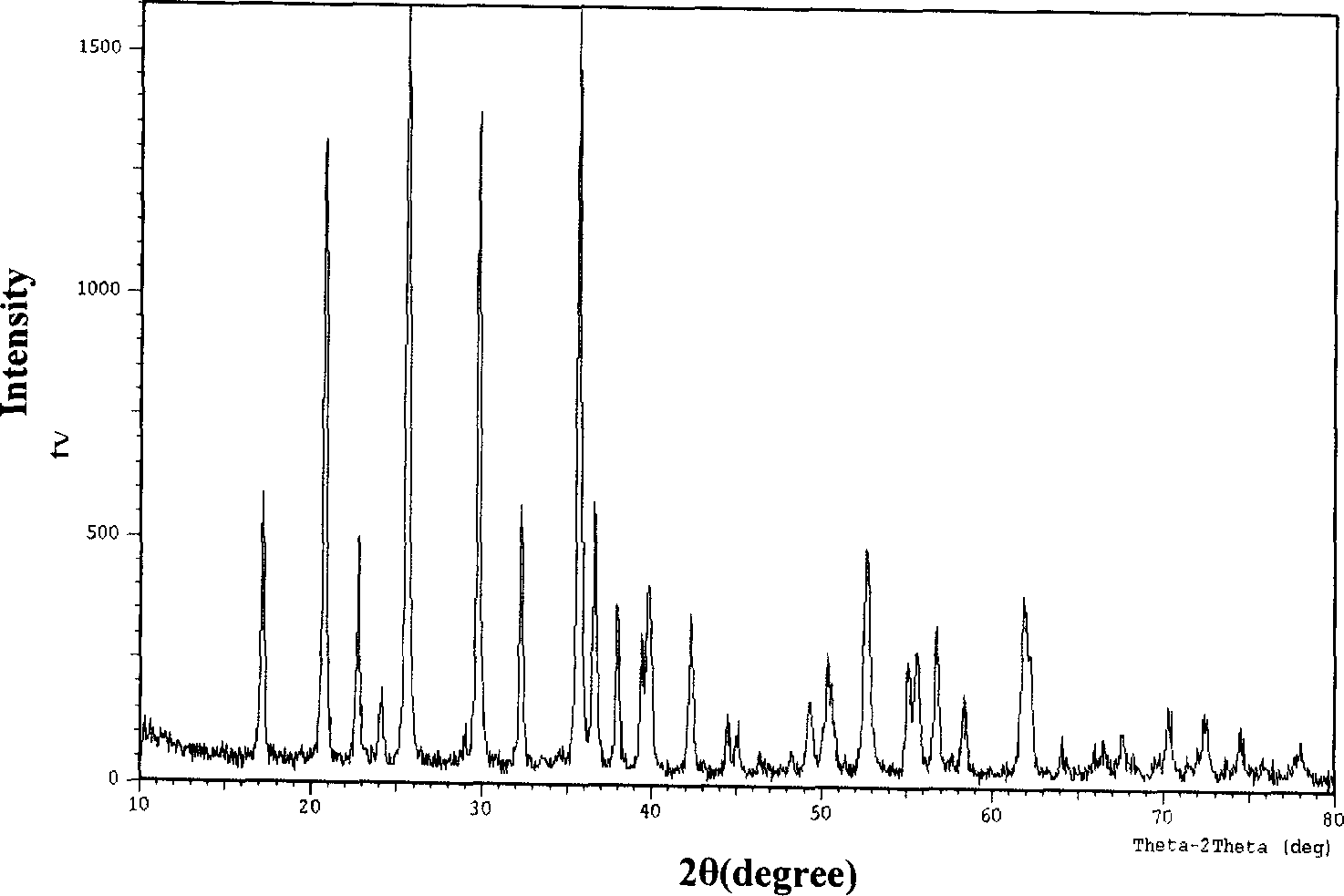

[0018] Example 1: 0.05mol lithium carbonate, 0.05mol ferric oxide, and 0.1mol ammonium dihydrogen phosphate are mixed (the required weight can be calculated by the number of moles × molecular weight), and 1.25 grams of nylon-66 is added, and 15ml of nylon-66 is used Glacial acetic acid was added after heating to dissolve. Then add 10ml of absolute ethanol, ball mill the sample on a ball mill at a speed of 300 / min for 8 hours, and dry to obtain the sample. Under sealed conditions, the sample was quickly heated to 650 °C for 8 hours at a constant temperature for 30-60 minutes, and then naturally cooled to room temperature. The prepared LiFePO 4 Grind into powder in a ball mill. The obtained products were analyzed by X-ray diffraction, showing that they were all olivine-type LiFePO 4 , the crystal structure is complete.

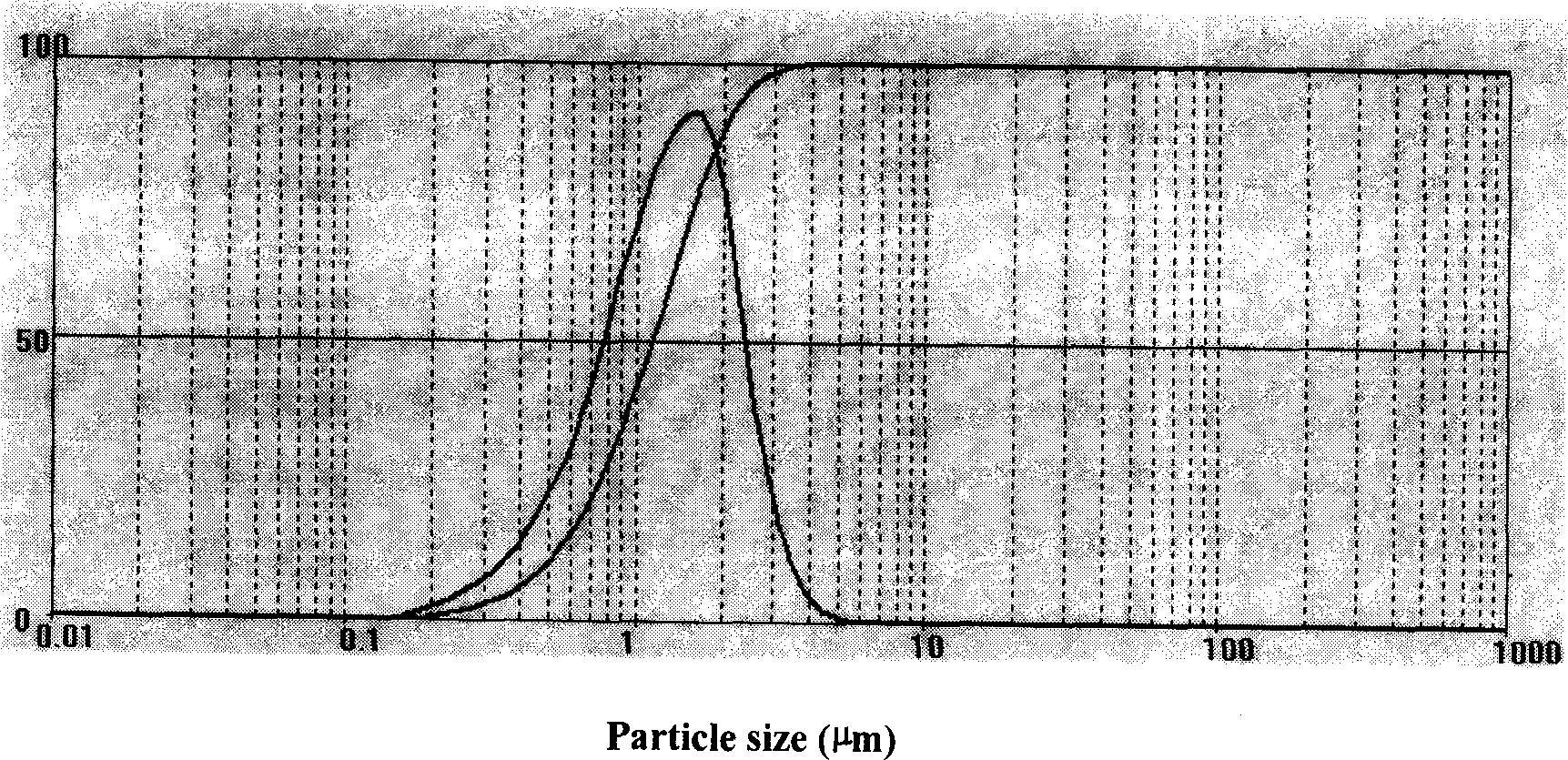

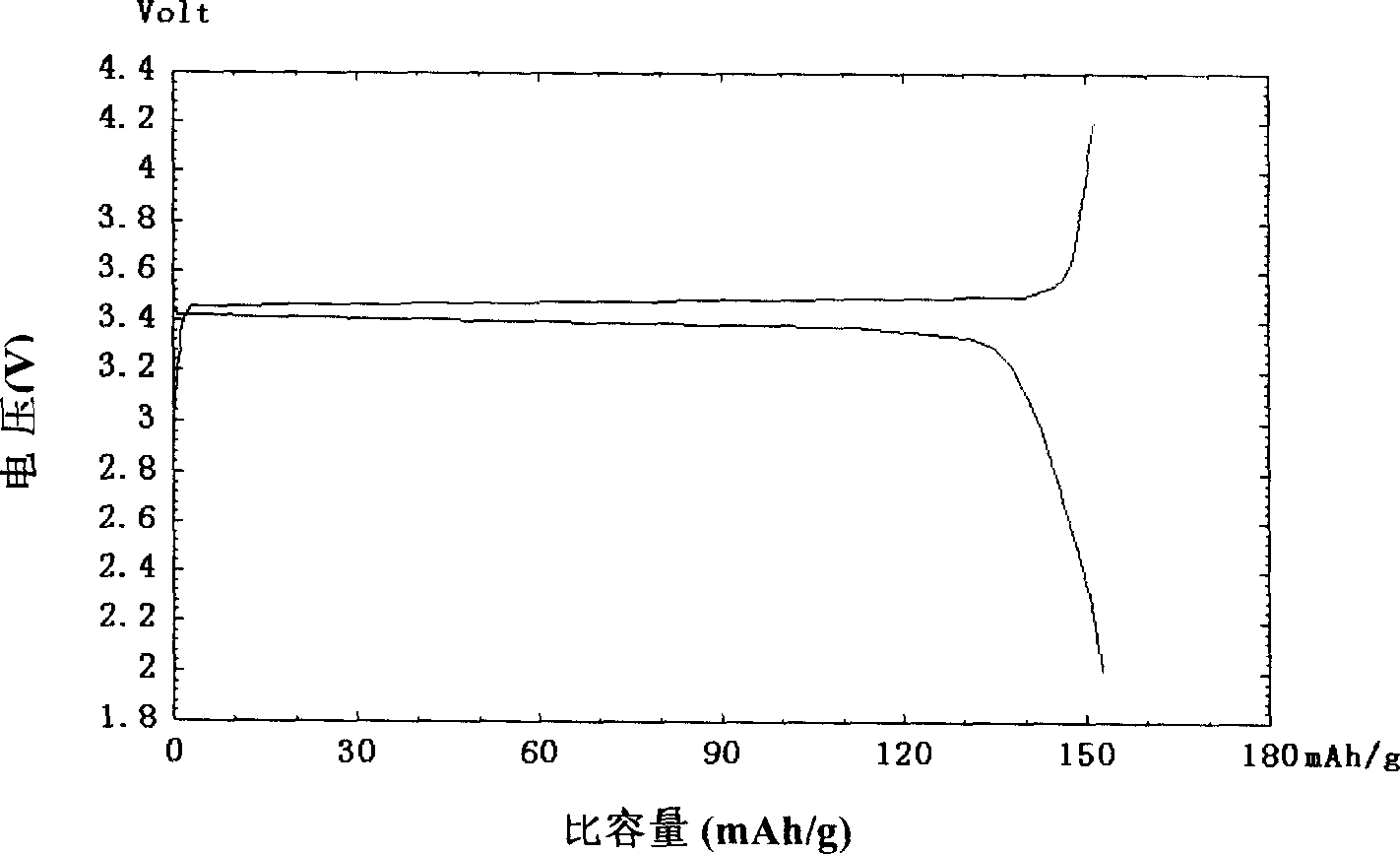

[0019] The average particle size of the powder is 1-3 μm after particle size analysis. The obtained product was assembled into an experimental battery, mixe...

Embodiment 2

[0020] Example 2: Mix 0.15mol lithium nitrate, 0.05mol ferric oxide, 0.15mol ammonium dihydrogen phosphate and 4.00 grams of lactose, add 30ml of 95% ethanol, ball mill for 2 hours at a speed of 300 / min on a ball mill, and dry to obtain a sample . Under sealed conditions, the sample was quickly heated to 650 ° C for 6 hours at a constant temperature for 30-60 minutes, and then naturally cooled to room temperature. The prepared LiFePO 4 Grind into powder in a ball mill. The obtained products were analyzed by X-ray diffraction, showing that they were all olivine-type LiFePO 4 , the crystal structure is complete.

[0021] The average particle size of the powder is 1-3 μm after particle size analysis. The resulting product was assembled into an experimental battery, as in Example 1. Use a constant current discharge meter to measure the charge and discharge specific capacity at 0.3mA / cm 2 Constant current discharge, the first discharge specific capacity is 150mAh / g.

Embodiment 3

[0022] Embodiment 3: with 0.05mol lithium carbonate, 0.05mol ferric oxide, 0.1mol ammonium dihydrogen phosphate, 3.00 gram lactose, add 1% Dy by the weight ratio of iron 2 o 3 Mix, add 20ml of absolute ethanol, ball mill on a ball mill at a speed of 300 / min for 4 hours, and dry to obtain a sample. Under sealed conditions, the sample was quickly heated to 650 °C for 12 hours at a constant temperature for 30-60 minutes, and then naturally cooled to room temperature. The prepared LiFePO 4 Pulverize into powder in a ball mill.

[0023] The resulting products were analyzed by X-ray diffraction, showing that they were all olivine LiFePO 4 , the crystal structure is complete. The average particle size of the powder is 1-3 μm after particle size analysis. The resulting product was assembled into an experimental battery, as in Example 1. Use a constant current discharge meter to measure the charge and discharge specific capacity at 0.3mA / cm 2 Constant current discharge, the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com