Method for preparing carbon nano tube/polymer nano composite material

A technology of nanocomposite materials and carbon nanotubes, which is applied in the field of nanometers, can solve problems such as carbon nanotube structure damage and complex processes, and achieve the effect of simple and practical preparation methods and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

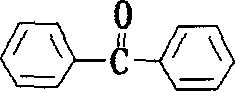

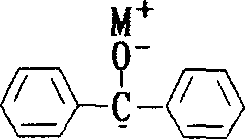

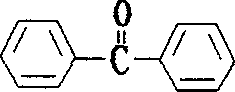

[0023] Take 1.22g of sodium metal, add it to 100ml of toluene, heat it to boil and vibrate vigorously to make the massive sodium metal into small particles with a diameter of less than 1mm, cool to room temperature, add dry tetrahydrofuran, add 3.5g of benzophenone, add 0.13 g of single-walled carbon nanotubes were stirred and reacted for 100 minutes. Take out the unreacted sodium metal, add styrene / methylstyrene (9:1), react at 20°C for 100 h, add ethanol to terminate the polymerization, collect the product, and dry it in vacuum to obtain 5.3 g of the product. Nano material properties: tensile strength 53.2MPa MPa, tensile modulus 3180MPa.

Embodiment 2

[0025] Take 1.8g of metal potassium and 1.2g of metal sodium, and add them to 100ml of dry tetrahydrofuran / toluene mixture (V / V=1:1), then add 9.1g of benzophenone and 0.11g of multi-walled carbon nanotubes, and stir After 30 hours, add 30ml of styrene, react at 100°C for 10min, add 10ml of methanol and 5ml of ethanol to terminate the reaction, filter, collect the product, and dry it in vacuum to obtain 4.6g of product. Nanomaterial properties: tensile strength 53.2MPa, tensile modulus 3510MPa.

Embodiment 3

[0027] Take 1.3g of potassium metal, add it to 100ml of toluene / tetrahydrofuran mixture (V / V=3:1), add 1.2g of benzophenone, add 0.1g of single-walled carbon nanotubes, stir at 25°C for 120h, add Methyl methacrylate / methyl acrylate / butyl acrylate 30ml (8:1:1), react at 50°C for 100h, add 10m of butanol to terminate the reaction, filter, collect the product, and dry it in vacuum to obtain 4.3g of product. Nanomaterial properties: tensile strength 62.2MPa, tensile modulus 3310MPa,

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com