Synthesis of solvent heat method nano strontium titanate powder

A technology of nano strontium titanate and strontium titanate, which is applied in the fields of titanium compounds, chemical instruments and methods, inorganic chemistry, etc., to achieve the effects of reducing equipment requirements, simple process, and cheap reaction raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A three-necked flask of 50 ml is fixed on a heat-collecting constant temperature magnetic stirrer, and a condenser, a thermometer, and a constant-pressure dropping funnel are installed on the three-necked flask. Under normal pressure, put 0.08mol of strontium chloride and 25ml of ethanol into a three-necked flask for mixing and stirring at 60°C, and adjust the pH to 8 with ammonia water to obtain suspension A, and beat 0.1mol of metatitanic acid in 15ml of ethanol to obtain a suspension For turbid solution B, inject B into a constant pressure dropping funnel, slowly drop into suspension A, and heat the oil bath with magnetic stirring. Timed reaction 4h.

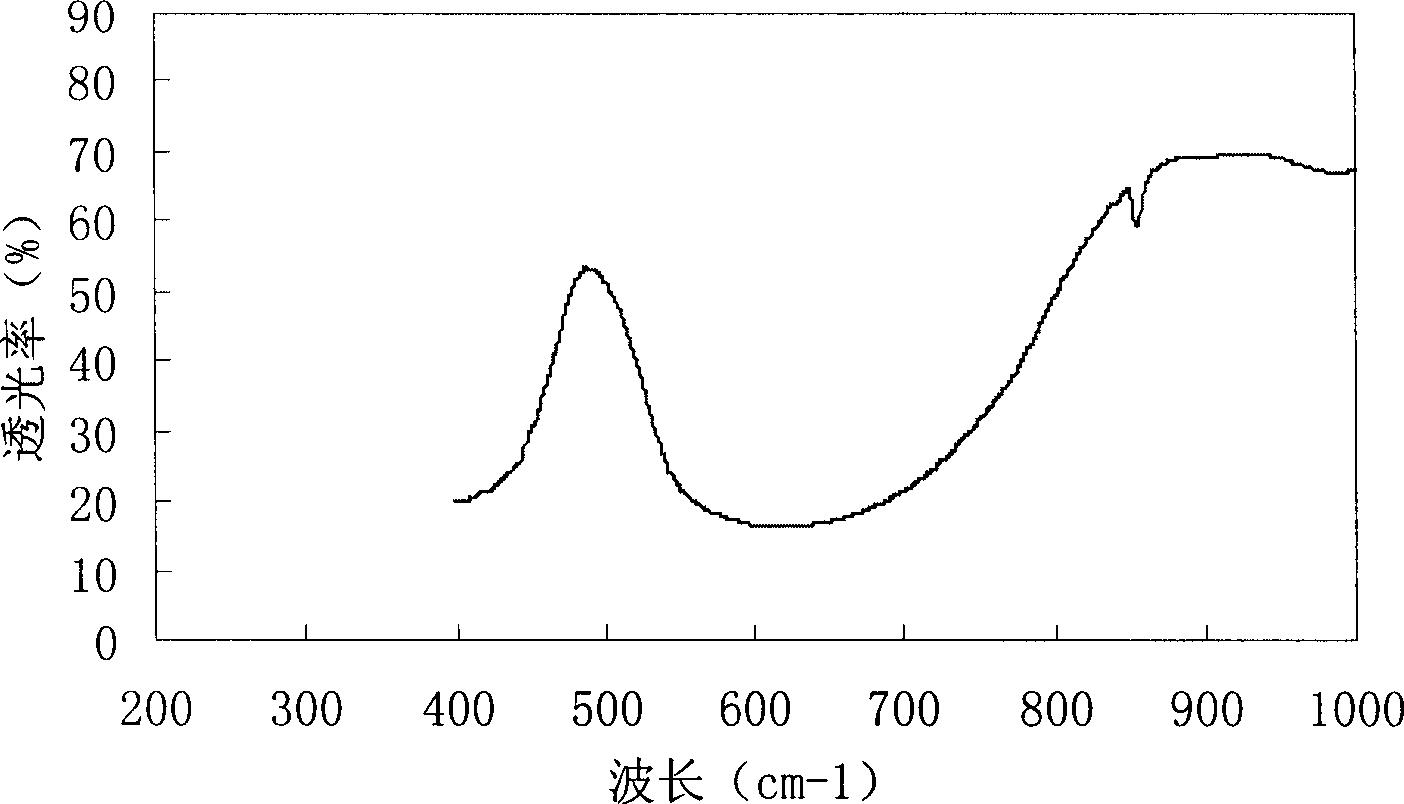

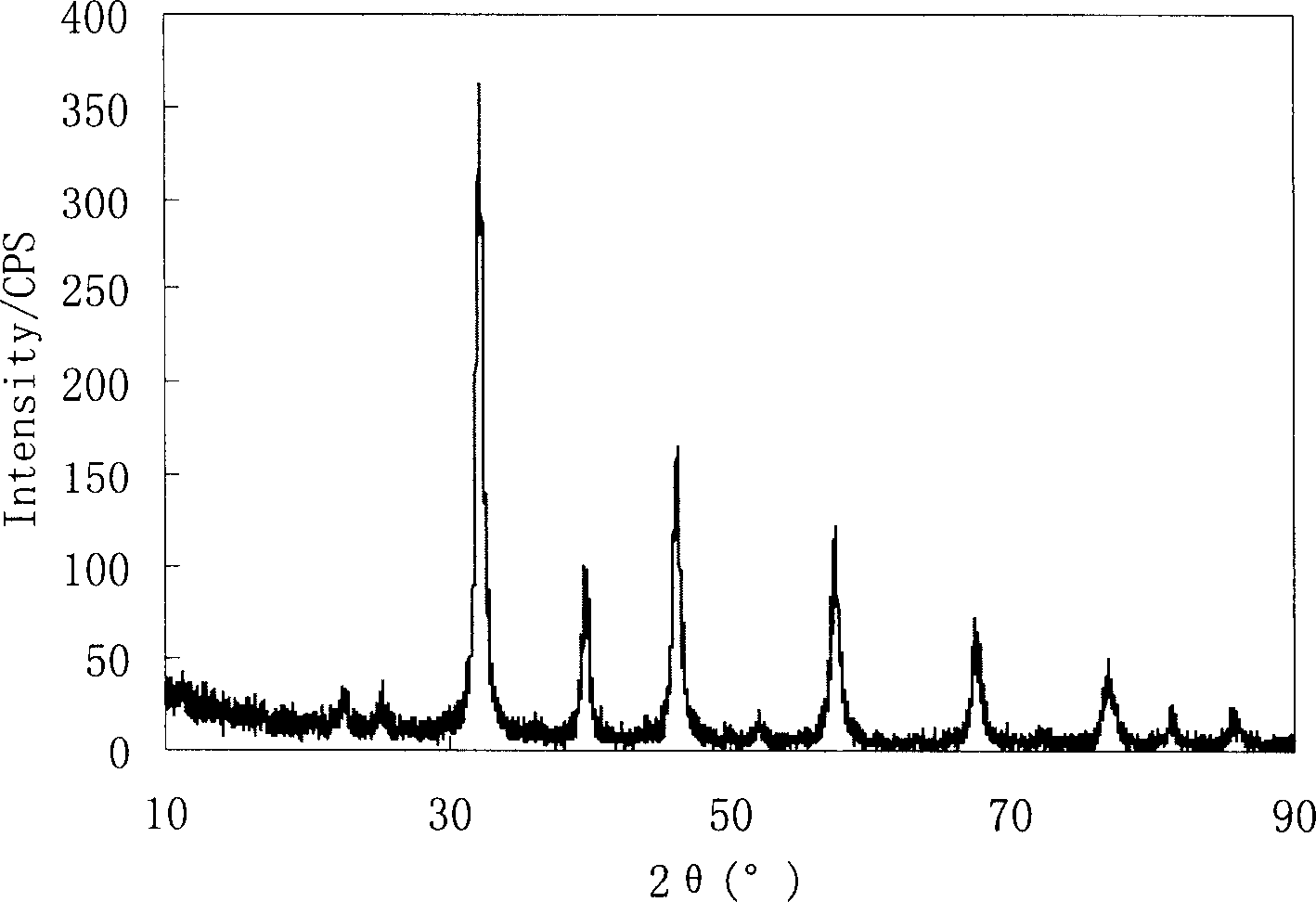

[0021] After the reaction is finished, the reaction liquid is filtered and processed to obtain the product. The titanium-strontium ratio of the product was 1.12 by chemical analysis. XRD analysis product is cubic phase. According to Scherrer's formula, the average primary particle diameter of strontium titanate was ...

Embodiment 2

[0023] A three-necked flask of 50 ml is fixed on a heat-collecting constant temperature magnetic stirrer, and a condenser, a thermometer, and a constant-pressure dropping funnel are installed on the three-necked flask. Under normal pressure, put 0.1mol strontium chloride and 15ml distilled water into a three-necked flask for mixing and stirring at 90°C, adjust the pH to 10 with potassium hydroxide to obtain suspension A; beat 0.1mol metatitanic acid in 15ml water, Obtain suspension B; inject B into a constant pressure dropping funnel, slowly drop into suspension A, and heat with magnetic stirring in an oil bath. Time the reaction for 1 h.

[0024] After the reaction is finished, the reaction liquid is filtered and processed to obtain the product. The titanium-strontium ratio of the product was found to be 1.03 by chemical analysis. XRD analysis product is cubic phase. According to Scherrer's formula, the average primary particle diameter of strontium titanate is calculated ...

Embodiment 3

[0026] A three-necked flask of 100 ml is fixed on a heat-collecting constant temperature magnetic stirrer, and a condenser tube, a thermometer, and a constant-pressure dropping funnel are installed on the three-necked flask. Under normal pressure, put 0.1mol of metatitanic acid and 40ml of propanol into a three-necked flask for slurry at 80°C to obtain a suspension A; mix and stir 0.12mol of strontium nitrate and 15ml of distilled water, adjust the pH to 10 with sodium hydroxide, Suspension B was obtained. Pour B into the constant pressure dropping funnel, slowly drop into the suspension A, and heat the oil bath with magnetic stirring. Timed reaction 6h.

[0027] After the reaction is finished, the reaction liquid is filtered and processed to obtain the product. The titanium-strontium ratio of the product was found to be 0.98 by chemical analysis. XRD analysis product is cubic phase. According to Scherrer's formula, the average primary particle diameter of strontium titana...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com