High-speed blended fiber-spinning process of nano composite antibacterial dacron POY

A nano-composite, high-speed spinning technology, which is applied in melt spinning, rayon manufacturing, textiles and papermaking, etc., can solve the problem that the polymerization and copolymerization method is not suitable for small batches, multi-variety production, high unevenness of physical performance indicators, dyeing, etc. Poor uniformity and other problems, to achieve the effect of improving clustering, reducing environmental requirements, and simplifying equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Take 5kg of antibacterial polyester masterbatches with a concentration of 15%w, 20-60nm silver, zinc, and silicon-based oxides, put them in an enamel plate, with a stacking thickness of 10cm, put them in a vacuum oven, heat up to 85°C, and keep warm for 2 hours. Slices are pre-crystallized. Continue to heat up to 105°C, keep warm for 5 hours, turn off the power, and cool naturally, with a moisture content of 50ppm.

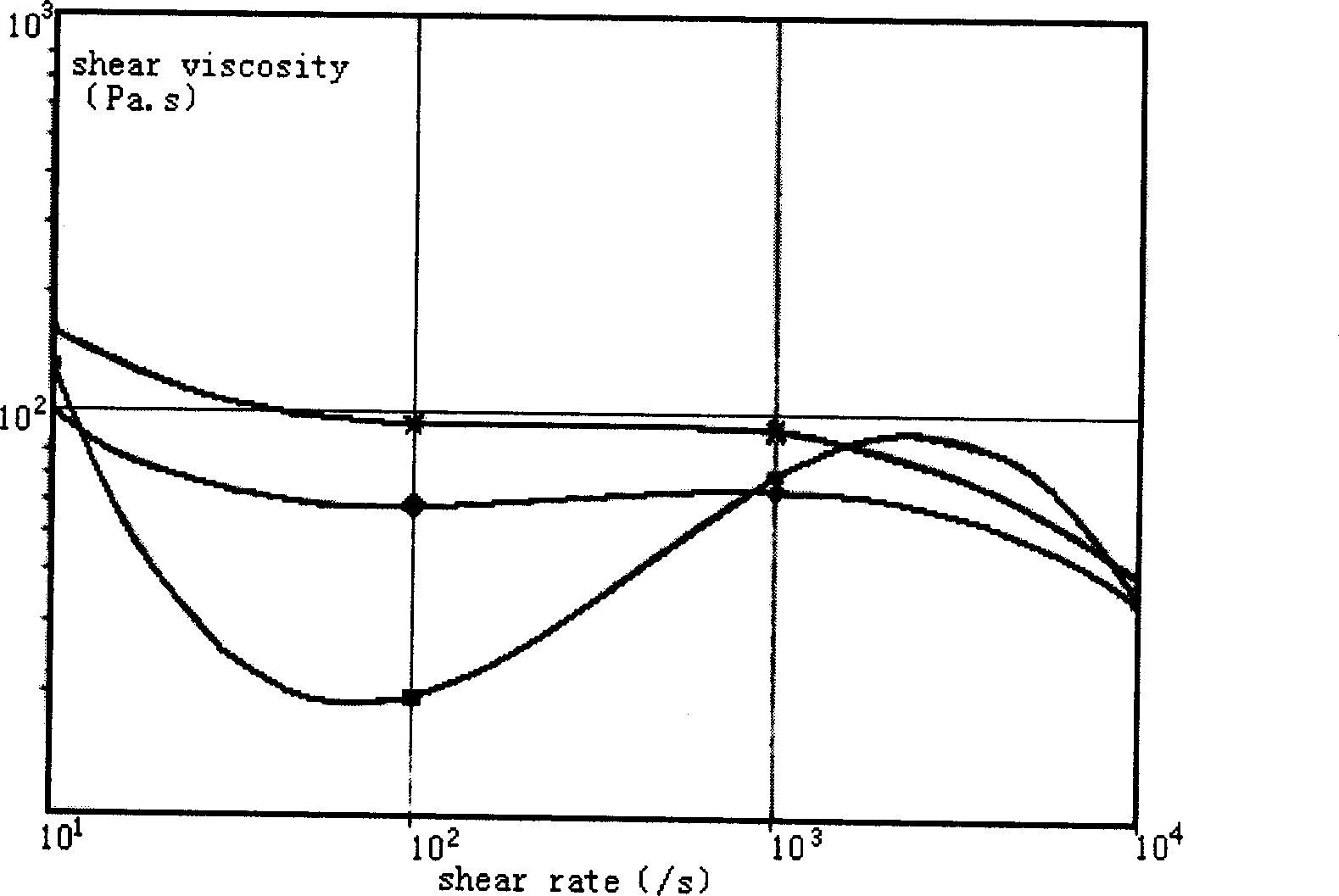

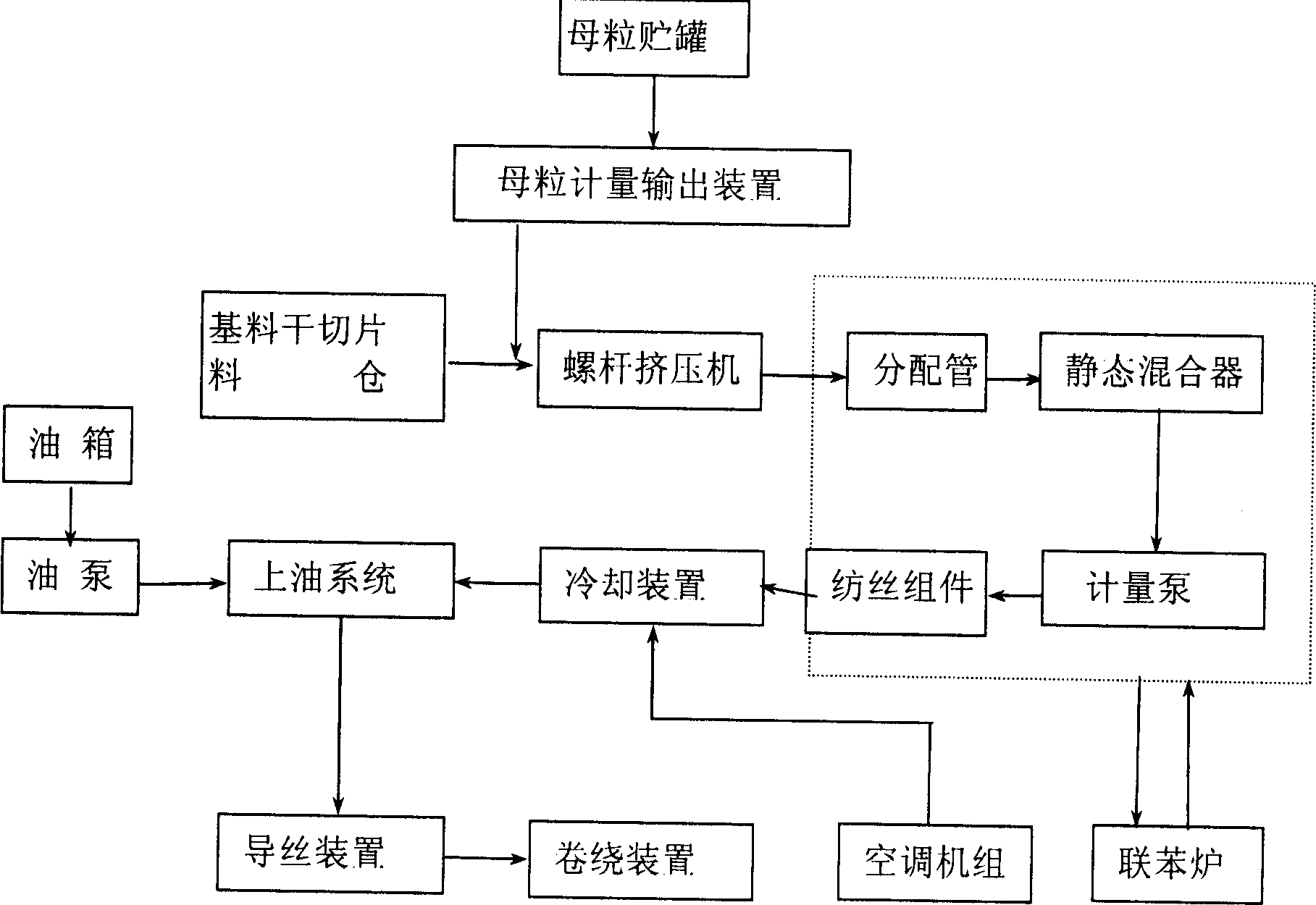

[0045] With the addition of 4.7% nano-antibacterial masterbatch, adjust the frequency of the injection machine to 45.5Hz, evenly transport it to the feed port of the extruder, mix it with polyester dry chips, enter the screw extruder to heat, melt and compress, and control the display table Temperature, zone I 295°C, zone II 302°C, zone III 299°C, zone IV 296°C, zone V 293°C, biphenyl furnace temperature 287°C, head melt temperature 295°C, melt pressure 100bar, by rotating screw The extruded blended melt enters the metering pump through the distribution pipe...

example 2

[0047] With the addition of 5.7% nano-composite antibacterial polyester masterbatch, adjust the frequency of the injection machine to 54Hz, and evenly transport it to the feed port of the extruder to mix with the polyester dry slices, and then enter the screw extruder to heat, melt, compress, and control the display table Temperature zone I is 293°C, zone II is 298°C, zone III is 296°C, zone IV is 294°C, zone V is 291°C. The melt pressure of the machine head is 100bar, the melt temperature is 293°C, and the temperature of the biphenyl furnace is 285°C. The blended melt extruded by the rotating screw enters the metering pump through the distribution pipe and the static mixer, and is delivered to the nozzle at a rate of 55g / min. The silk assembly is filtered, homogenized, and evenly distributed through a 50-mesh and 60-mesh sea sand layer, pressed into a 36f spinneret to form a thin stream of melt, cooled and formed in a 27°C silk room, and then the surface of the tow is coated w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com