Electrochromism device with polyaniline-polyvinyl alcohol compound film and preparation method thereof

An electrochromic device and polyvinyl alcohol technology, applied in the field of color-changing materials, can solve problems such as no electrochromic properties, and achieve the effects of good electrochromic properties and electrochemical activity, improved mechanical properties, and good performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

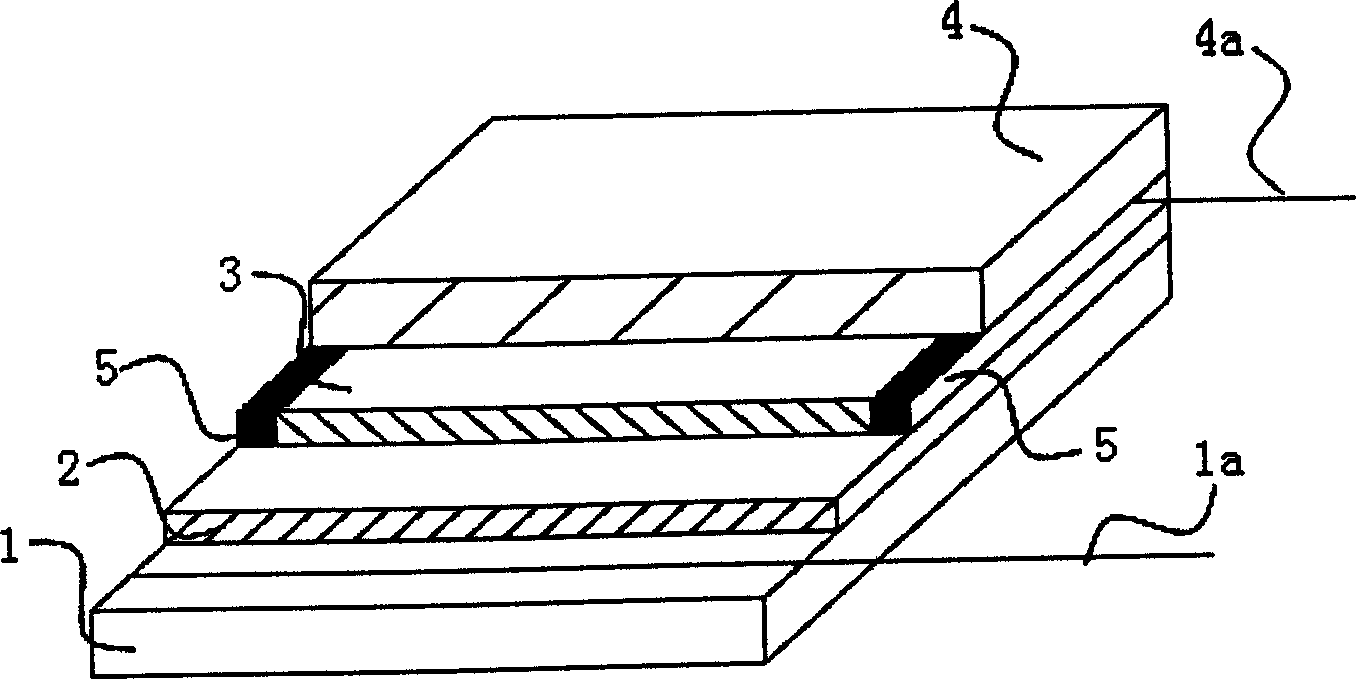

Image

Examples

Embodiment 1

[0039] The equipment used is: platinum sheet electrode, 1×1cm 2 , type 213; saturated calomel electrode, type 232; platinum wire electrode, Ag / AgCl reference electrode; ITO glass, square resistance 15Ω / □; electrochemical analyzer, CHI-830 type; Agilent 8453 ultraviolet spectrum analyzer; ZF -Type 3 potentiostat; two-compartment glass electrolytic cell.

[0040] Divide the area into 3.5×2.0cm 2 The ITO conductive glass is cleaned and dried with acetone, placed horizontally, and a polyvinyl alcohol aqueous solution with a concentration of 1wt% is cast on it, and dried at room temperature for 36 hours to obtain an indium tin oxide electrode covered with a polyvinyl alcohol film; The ITO conductive glass with polyvinyl alcohol film is used as the working electrode, the saturated calomel electrode is used as the reference electrode, and the 213-type platinum electrode is used as the counter electrode to form a three-electrode system. The electropolymerization solution is 1mol / L p...

Embodiment 2

[0045] The equipment used is: platinum sheet electrode, 1×1cm 2 , type 213; saturated calomel electrode, type 232; platinum wire electrode, Ag / AgCl reference electrode; ITO glass, square resistance 15Ω / □; electrochemical analyzer, CHI-830 type; Agilent 8453 ultraviolet spectrum analyzer; ZF -Type 3 potentiostat; two-compartment glass electrolytic cell.

[0046] Divide the area into 3.5×2.0cm 2 The ITO conductive glass is cleaned and dried with acetone, placed horizontally, and a polyvinyl alcohol aqueous solution with a concentration of 1wt% is cast on it, and dried at room temperature for 48 hours to obtain an indium tin oxide electrode covered with a polyvinyl alcohol film; The ITO conductive glass with polyvinyl alcohol film is used as the working electrode, the saturated calomel electrode is used as the reference electrode, and the 213-type platinum electrode is used as the counter electrode to form a three-electrode system. The electropolymerization solution is hydrochl...

Embodiment 3

[0050] The equipment used is: platinum sheet electrode, 1×1cm 2 , type 213; saturated calomel electrode, type 232; platinum wire electrode, Ag / AgCl reference electrode; ITO glass, square resistance 15Ω / □; electrochemical analyzer, CHI-830 type; Agilent 8453 ultraviolet spectrum analyzer; ZF -Type 3 potentiostat; two-compartment glass electrolytic cell.

[0051] Divide the area into 3.5×2.0cm 2 The ITO conductive glass is cleaned and dried with acetone, placed horizontally, and a polyvinyl alcohol aqueous solution with a concentration of 2.5wt% is cast on it, and dried at room temperature for 60 hours to obtain an indium tin oxide electrode covered with a polyvinyl alcohol film; to cover The ITO conductive glass with polyvinyl alcohol film is used as the working electrode, the saturated calomel electrode is used as the reference electrode, and the 213-type platinum electrode is used as the counter electrode to form a three-electrode system. The electropolymerization solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com