Microwave absorbing composite material with silicon carbide-carbon and preparation process thereof

A composite material and microwave absorption technology, applied in the field of ceramic matrix composite materials, can solve problems such as complex process, high density, and limited application range, and achieve the effects of low preparation cost, good high temperature performance, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The process steps are:

[0027] (1) The matrix powder is selected as D 50 = 0.2-2μm β-SiC particle powder, its purity should be greater than 95wt%, and D 50 =0.5-5μm graphite C particle powder, and add 0.5-2wt% sintering aid. such as BAC or Al 2 o 3 , the addition amount is 0.5-2wt% of the silicon carbide-carbon matrix, that is, an additional row λ plus λ. Wherein the content of C or graphite is 1-20wt% of the total content of the composite powder.

[0028] (2) After mixing the prepared powder on a ball mill with alcohol as a solvent for 24 hours, add 5-15vol% phenolic resin solution as a binder, and after mixing for another 5 hours, take it out, dry it, grind it, and pass it through 60 mesh Sieve and set aside.

[0029] (3) The composite powder is pressed and formed on a flat vulcanizing machine, the forming pressure is about 20MPa, the pressure is kept for 20s, and sintered at 1800-2250°C under the protection of Ar in a high-temperature sintering furnace.

[00...

Embodiment 2

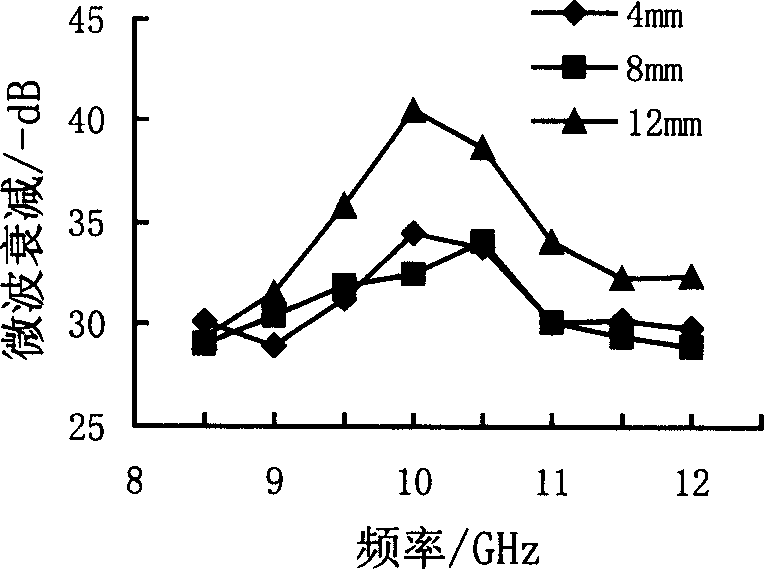

[0035] Adopt hot pressing mode to carry out sintering, and sintering temperature is 1700-2050 ℃, and pressure is 20-40MPa, and other is as embodiment 1, and its microwave performance is as follows: figure 1 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com