Formula of a glass ceramic material and preparation method

A technology of glass ceramics and substrates, which is applied in the formulation and preparation of multilayer wiring substrate materials, and can solve the problems of low firing temperature, high insulation resistance, easy softening and deformation of glass, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0060] SiO in BSG materials 2 , B 2 o 3 、K 2 O, Na 2 The content of each component of O is: SiO 2 62wt%, B 2 o 3 34wt%, K 2 O 2wt%, Na 2 O 2wt%; final substrate materials BSG and SiO 2 The content of each component is: BSG55wt%, SiO 2 45% by weight.

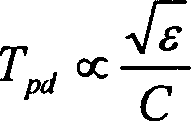

[0061] The glass-ceramic substrate material prepared according to the above formula ratio and the above-mentioned preparation steps has various performance indicators: at a working frequency of 1MHz, the dielectric constant ε-3 ;Insulation resistivity ρ≥1.3×10 13 Ω·cm, compressive strength E≥7×10 7 V / m, flexural strength ≥ 200Mpa, thermal expansion coefficient α≈3.6×10 -6 / ℃, thermal conductivity k≥1W / m·K.

Embodiment approach 2

[0063] SiO in BSG material 2 , B 2 o 3 、K 2 O, Na 2 The content of each component of O is: SiO 2 62wt%, B 2 o 3 34wt%, K 2 O 2wt%, Na 2 O 2wt%; final substrate materials BSG and SiO 2 The content of each component is: BSG70wt%, SiO 2 30 wt%.

[0064] The glass-ceramic substrate material prepared according to the above formula ratio and the above-mentioned preparation steps has various performance indicators: at a working frequency of 1MHz, the dielectric constant ε-3 ;Insulation resistivity ρ≥1.6×10 13 Ω·cm, compressive strength E≥7×10 7 V / m, flexural strength ≥ 200Mpa, thermal expansion coefficient α≈3.6×10 -6 / ℃, thermal conductivity k≥1W / m·K.

Embodiment approach 3

[0066] SiO in BSG materials 2 , B 2 o 3 、K 2 O, Na 2 The content of each component of O is: SiO 2 62wt%, B 2 o 3 34wt%, K 2 O 2wt%, Na 2 O 2wt%; final substrate materials BSG and SiO 2 The content of each component is: BSG90wt%, SiO 2 10 wt%.

[0067] The glass-ceramic substrate material prepared according to the above formula ratio and the above-mentioned preparation steps has various performance indicators: at a working frequency of 1MHz, the dielectric constant ε-3 ;Insulation resistivity ρ≥1.8×10 13 Ω·cm, compressive strength E≥7×10 7 V / m, flexural strength ≥ 200Mpa, thermal expansion coefficient α≈3.6×10 -6 / ℃, thermal conductivity k≥1W / m·K.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com