Amino acid intercalation manganese dioxide and its preparation method

A technology of manganese dioxide and amino acids, applied in chemical instruments and methods, manganese oxide/manganese hydroxide, inorganic chemistry, etc., can solve problems such as intercalation difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 200mL containing 0.6mol / L NaOH and 1.5mol / L H 2 o 2 The mixed solution was quickly added to 100mL containing 0.4mol / L Mn(NO 3 ) 2 solution, stirred vigorously for 30 minutes, filtered, transferred the filter cake to a 100mL polytetrafluoroethylene cup, added 40mL NaOH solution with a concentration of 2mol / L, stirred to form a paste, sealed the polytetrafluoroethylene cup in water In a hot kettle, hydrothermal treatment was carried out at 160°C for 15 hours. After the hydrothermal kettle was naturally cooled to room temperature, the kettle was opened for suction filtration, and the filter cake was washed with deionized water until the pH value of the filtrate was 8. The filter cake was dried in an air atmosphere at 70° C. for 9 hours to obtain layered manganese dioxide.

[0043] Weigh 2.5g of layered manganese dioxide solid powder and add to 300mL of HNO with a concentration of 1.0mol / L 3 solution, stirred at room temperature for 3 days, during which a new 1.0mol / L ...

Embodiment 2

[0048] 200mL containing 0.8mol / L NaOH and 1.2mol / L H 2 o 2 The mixed solution was quickly added to 100mL containing 0.4mol / L Mn(NO 3 ) 2 solution, stirred vigorously for 20 minutes, filtered, transferred the filter cake to a 100mL polytetrafluoroethylene cup, added 50mL NaOH solution with a concentration of 3mol / L, stirred to form a paste, sealed the polytetrafluoroethylene cup in water In a hot kettle, hydrothermal treatment was carried out at 150°C for 20 hours. After the hydrothermal kettle was naturally cooled to room temperature, the kettle was opened for suction filtration, and the filter cake was washed with deionized water until the pH value of the filtrate was 9. The filter cake was dried in an air atmosphere at 80° C. for 6 hours to obtain layered manganese dioxide.

[0049] Weigh 2.5g of layered manganese dioxide solid powder and add to 280mL of HNO with a concentration of 1.5mol / L 3 solution, stirred and reacted at room temperature for 3 days, during which a n...

Embodiment 3

[0054] Manganese dioxide stripping method is the same as in Example 1.

[0055] Take exfoliated manganese dioxide and add it to deionized water to make 100mL of exfoliated manganese dioxide sol with a manganese dioxide content of 0.04mol / L; Concentration is the hydrochloric acid solution of 0.1mol / L to adjust the pH value to 8, according to L-lysine and MnO 2 Mix the two solutions at a molar ratio of 0.2:1, stir and react at 40°C for 24 hours, filter, wash with deionized water for 3 to 4 times, and clean the L-lysine adsorbed on the surface of the precipitate, and then in air at 70°C Let dry for 12 hours.

[0056] Adopt the method for embodiment 1 to analyze product, obtain its chemical composition as:

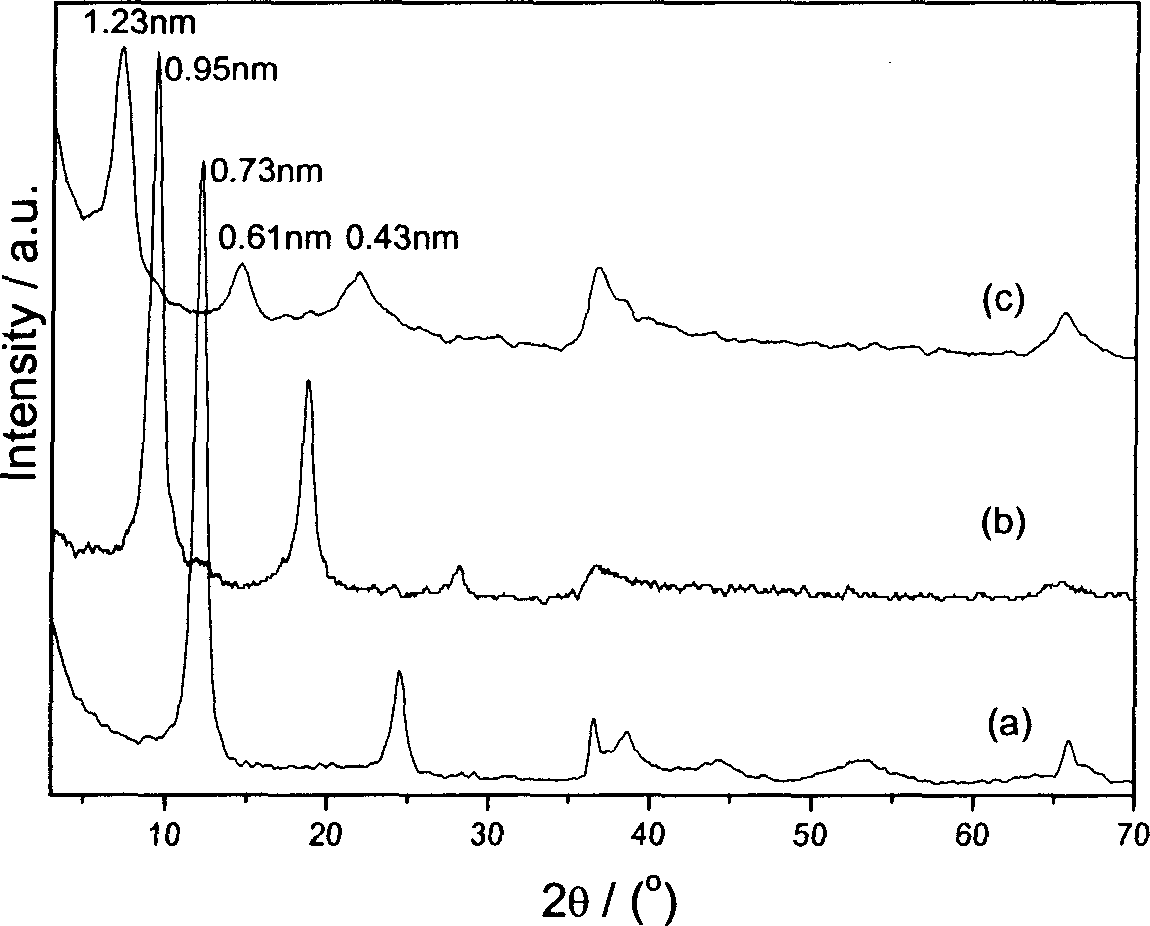

[0057] Na 0.043 h 0.067 (C 4 h 12 N) 0.070 (C 6 h 15 N 2 o 2 ) 0.050 MnO 2 0.38H 2 O, X-ray powder diffraction analysis results see image 3 (c), d 001 It is 0.89nm, indicating that L-lysine is successfully inserted into the manganese dioxide layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com