Method for extracting high purity protein from cow milk or soybean waste water

A high-purity, whey-water technology, applied in peptide preparation methods, chemical instruments and methods, organic chemistry, etc., can solve problems such as low-cost large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

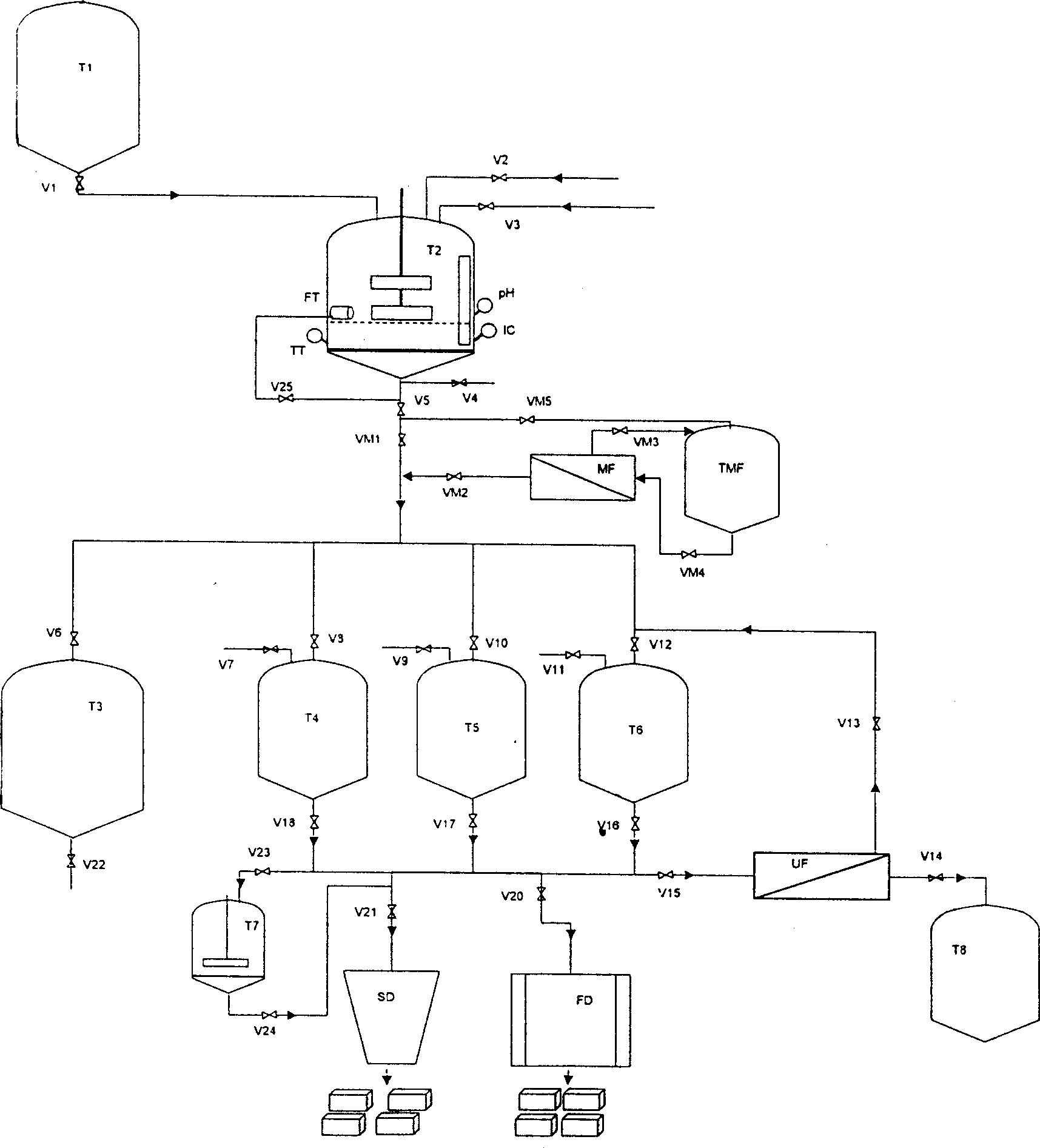

[0046] Example 1: 993 liters of semi-skimmed milk, temperature 8.2 degrees C, pH 6.6, total protein 32.5 grams per liter, BLP concentration 366 mg per liter, BLF concentration 138 milliliters per liter. Use the process route in Figure 1 and follow the steps described in the instructions to produce mixed protein powder of BLP and BLF. Stirring tank T2 contains SPEC70 resin. The adsorption time is 115 minutes. Add 90 liters of 5.5% sodium chloride brine during solution, and the solution time is 65 minutes. The solution and eluate are combined into the microfiltration unit (0.1 micron microfiltration membrane) for microfiltration to remove bacteria and fat. 136 liters of the filtrate is sent to the ultrafiltration membrane unit (30K molecular cut-off) for desalination and concentration. A concentrated solution of 0.52 liters was collected. Adopt freeze-drying method to obtain light brown green dry powder 351 grams, water content 4.3%, total protein is 93.2%, ash content 2.6%....

Embodiment 2

[0047] Example 2: 996 liters of skim milk, pH 6.7, temperature 6.6 degrees C, total protein is 32.9 grams per liter, BLP concentration is 378 mg per liter, BLF concentration is 129 mg per liter. Use the process route in Figure 1 and follow the steps described in the instructions to produce monomeric BLP protein and monomeric BLF protein. Add the SPEC70 resin stirring tank inside to absorb for 115 minutes, and the stirring speed is 60rpm. After collecting the absorbed milk, rinse the resin with RO water. Add 90 liters of first-stage brine (2.4%) to decompose for 36 minutes, stirring at a speed of 30 rpm. Collect the first stage BLP solution and add 2.3% saline to rinse the resin for 3 times. Merge the eluate into the BLP solution and use a microfiltration membrane to remove bacteria and fat.

[0048] At the same time as BLP microfiltration, 86 liters of 4.9% brine was added to the stirring tank for BLF desorption, and the stirring speed was 36 rpm. The solution time is 60 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com