Method for making plasma display screen lower substrate

A technology of a plasma display screen and a manufacturing method, which is applied in the field of manufacturing the lower substrate of the plasma display screen, can solve the problems of inaccurate alignment, glass deviation, waste of energy of a sintering furnace, etc., and achieves reduction of deformation, production cost, and printing medium. and the effect of the process of sintering the medium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in further detail below in conjunction with the accompanying drawings.

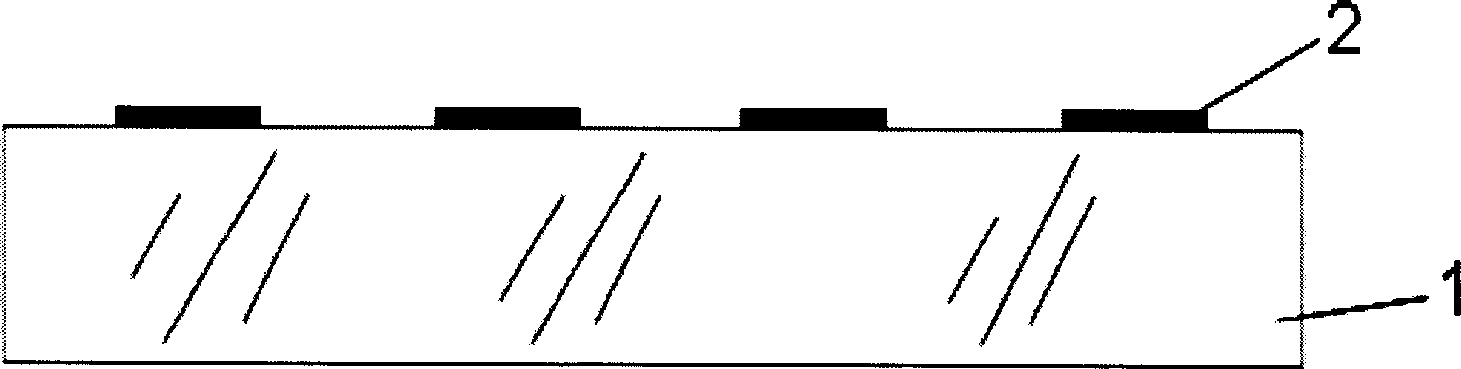

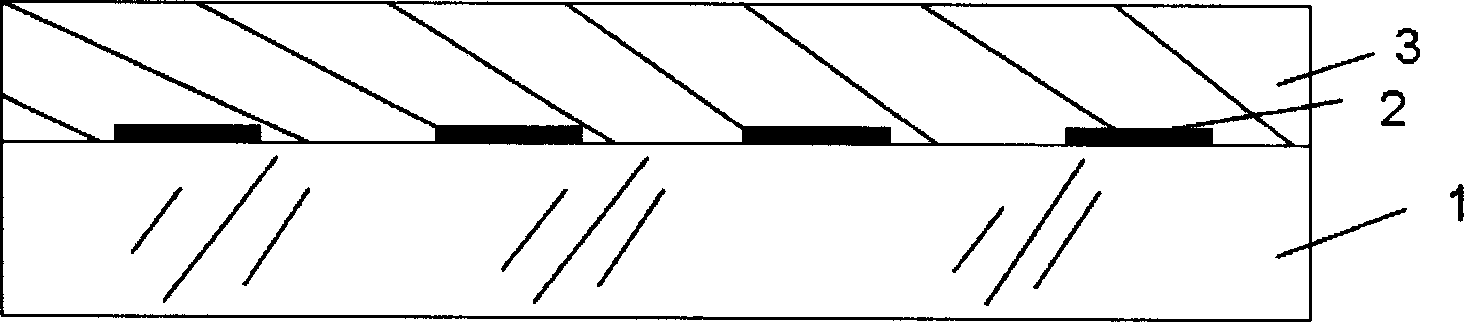

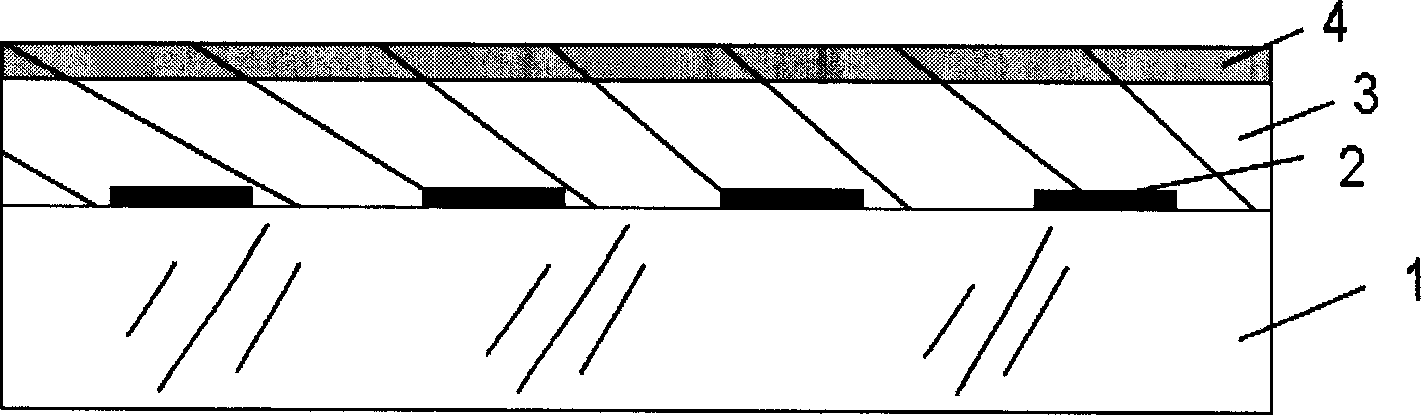

[0009] see figure 1 , 2, 3, first, on the glass substrate 1 with the address electrode pattern 2, print a white barrier paste with a thickness of 180um-220um and a black barrier paste with a thickness of 20um-50um, and then print it at 130°C-160°C Dried down to form a white barrier layer 3 and a black barrier layer 4, and the total thickness of the white barrier layer 3 and the black barrier layer 4 is equal to the height of the dielectric layer and the barrier layer; see Figure 4 , 5, secondly, sintering the white barrier slurry layer 3 and the black barrier slurry layer 4 at 550°C-570°C; then, paste a layer of acid-resistant and alkali-resistant photosensitive resist on the sintered black barrier layer 4 Dry film or directly print or apply a photosensitive resist film to form a resist layer 5, and then use a barrier master to expose and develop the resis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com