Zero-discharge reclamation method of electroplating wastewater and apparatus thereof

An electroplating wastewater, zero-discharge technology, applied in metallurgical wastewater treatment, water/sewage treatment, water/sludge/sewage treatment, etc. The effect of control and process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

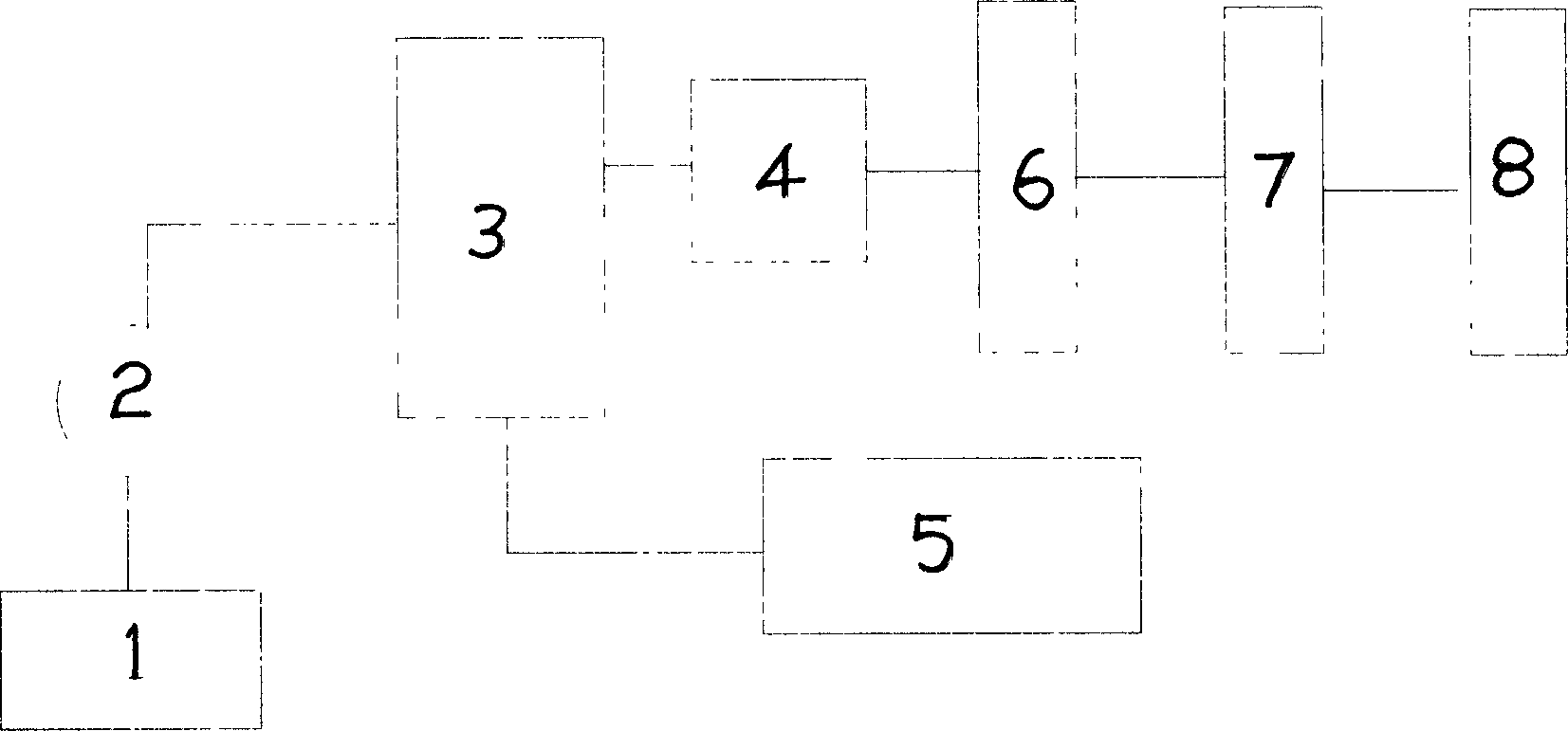

[0034] use figure 1 The equipment treats copper-containing wastewater.

[0035] Add precipitant sodium hydroxide to the copper-containing wastewater reaction tank to adjust the pH range to 8; introduce the treated copper-containing wastewater into a solid-phase separation device for preliminary solid-phase separation to obtain a solid phase and a liquid phase, and carry out solid phase separation Recover after press filtration, after filtering the liquid phase, process it through an ion exchange device to obtain clear water, and recover the clear water;

[0036] The solid phase separation device is an inclined tube sedimentation tank, the ion exchange device is an ion exchange column, and the exchangers used in the ion exchange column are hydrochloric acid and sodium hydroxide.

Embodiment 2

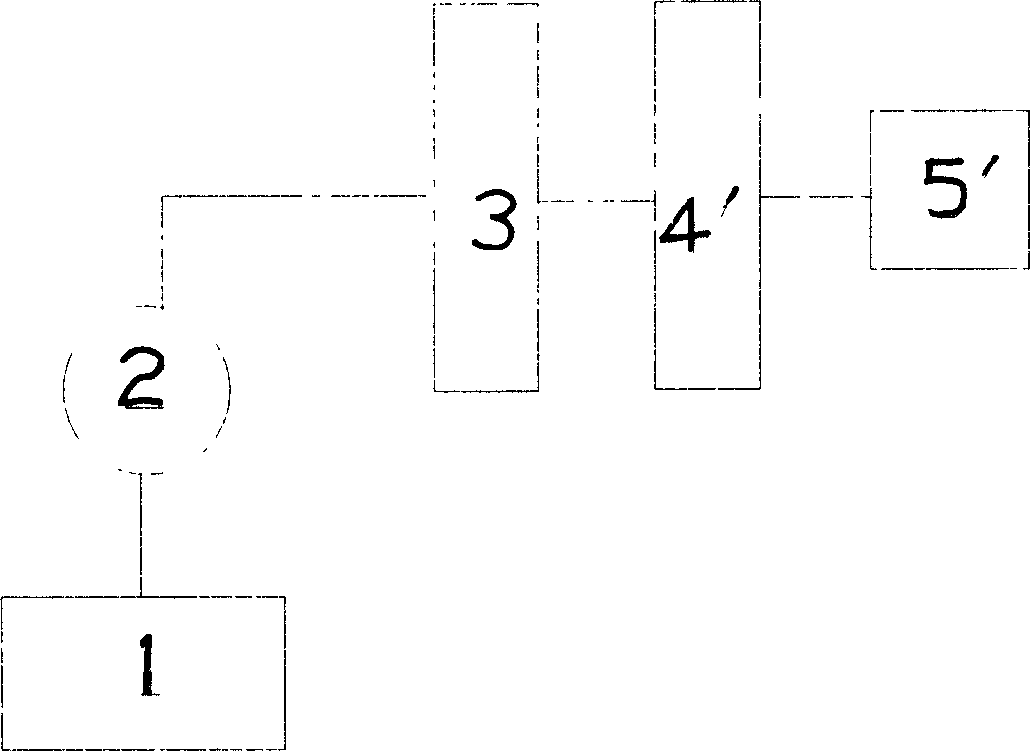

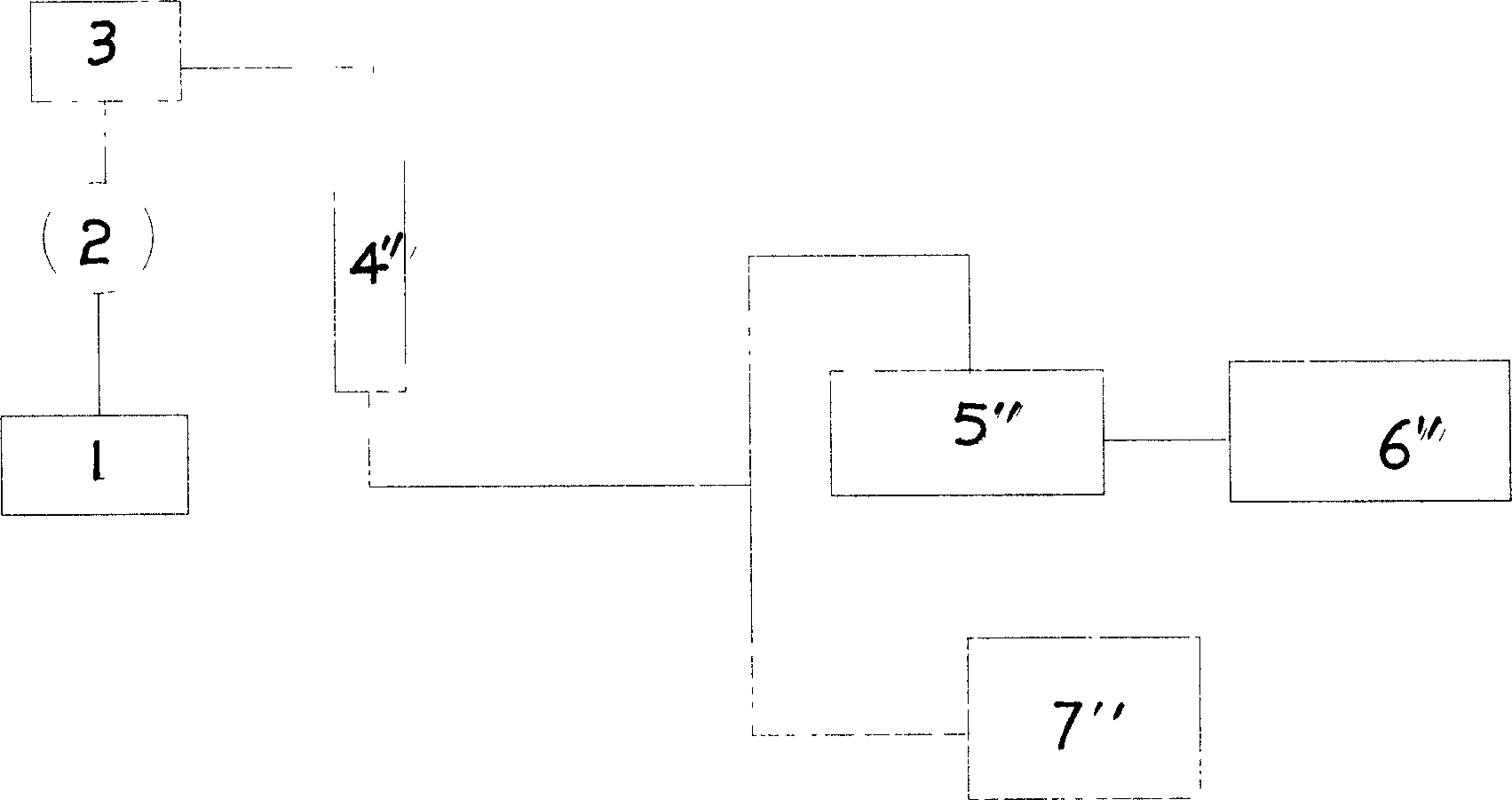

[0037] Embodiment 2 uses figure 1 , 2 , The device shown in 3 is processed.

[0038] The copper-containing wastewater, chromium-containing wastewater, cyanide-containing wastewater, nickel-containing wastewater, and pre-treatment wastewater are respectively introduced into the wastewater reaction tank;

[0039] Add precipitant sodium hydroxide to the copper-containing wastewater reaction tank, and adjust the pH range to 8.5;

[0040] The precipitant ferrous sulfate added in the chromium-containing wastewater reaction tank adjusts the pH value to 8.5;

[0041] The precipitating agent sodium hypochlorite added in the cyanide-containing wastewater reaction tank adjusts the pH value to 11;

[0042] The precipitating agent sodium carbonate that adds in the nickel-containing wastewater reaction tank adjusts the pH value to 5;

[0043] Adjust the pH range to 9 in the pretreatment wastewater reaction tank.

[0044] The treated copper-containing wastewater, chromium-containing was...

Embodiment 3

[0047] Embodiment 3 uses figure 1 , 2 , The device shown in 3 is processed.

[0048] The copper-containing wastewater, chromium-containing wastewater, cyanide-containing wastewater, nickel-containing wastewater, and pre-treatment wastewater are respectively introduced into the wastewater reaction tank;

[0049] Add precipitant sodium hydroxide to the copper-containing wastewater reaction tank, and adjust the pH range to 8;

[0050] The precipitating agent sodium metabisulfite added in the chromium-containing wastewater reaction tank adjusts the pH value to 7;

[0051] The precipitating agent sodium hypochlorite added in the cyanide-containing wastewater reaction tank adjusts the pH value to 11;

[0052] The precipitating agent sodium carbonate added in the nickel-containing wastewater reaction tank adjusts the pH value to 4.5;

[0053] Adjust the pH range to 6 in the pretreatment wastewater reaction tank.

[0054] The treated copper-containing wastewater, chromium-contain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com