Method for preparing 8-hydroxyquinoline aluminium/silicone oxide composite luminescent material

A technology of aluminum hydroxyquinoline and luminescent materials, which is applied in luminescent materials, chemical instruments and methods, and illuminated marks, and can solve problems such as poor chemical stability, device aging, and shortened service life, and achieve simple processes and high luminous intensity. High, strong chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

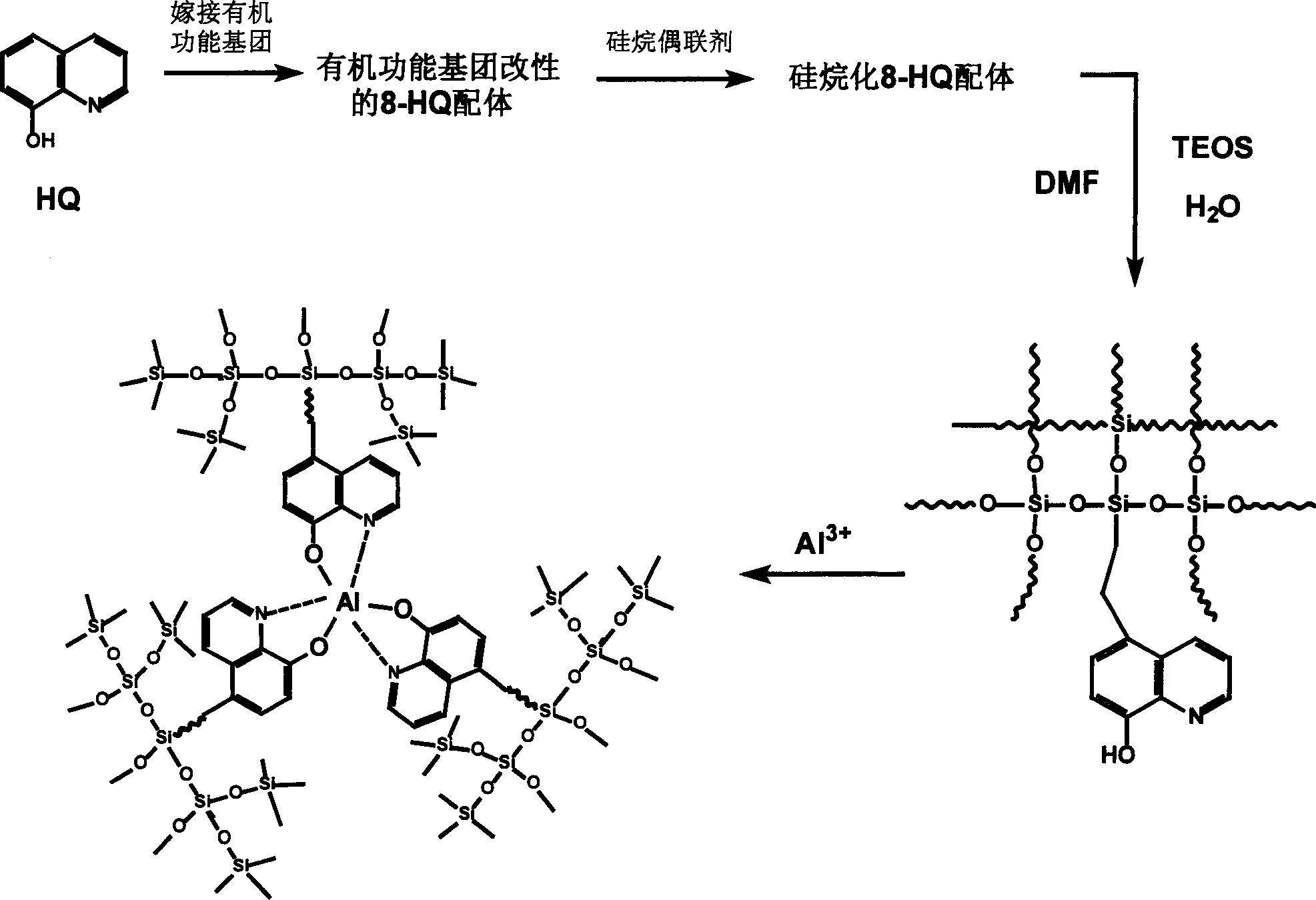

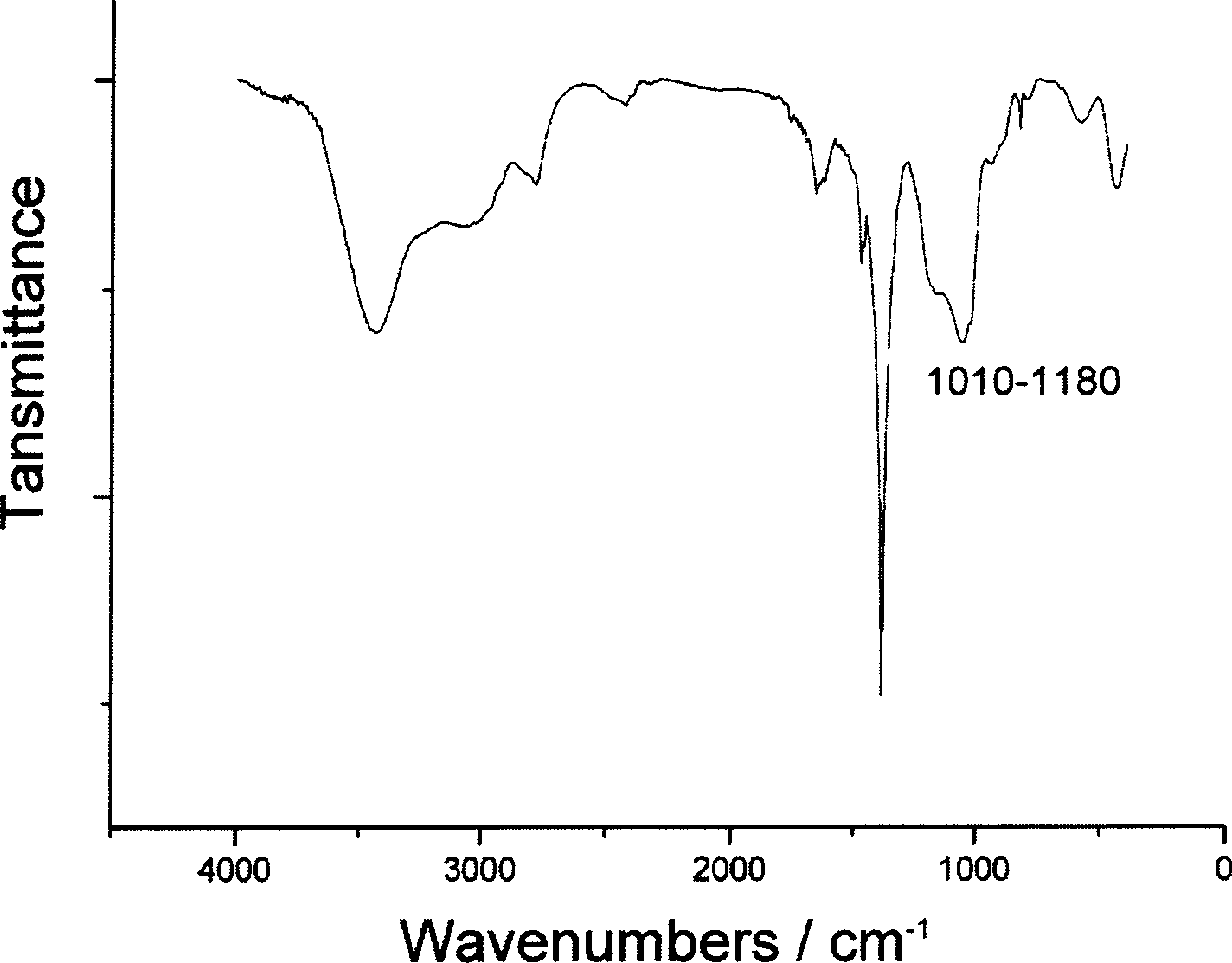

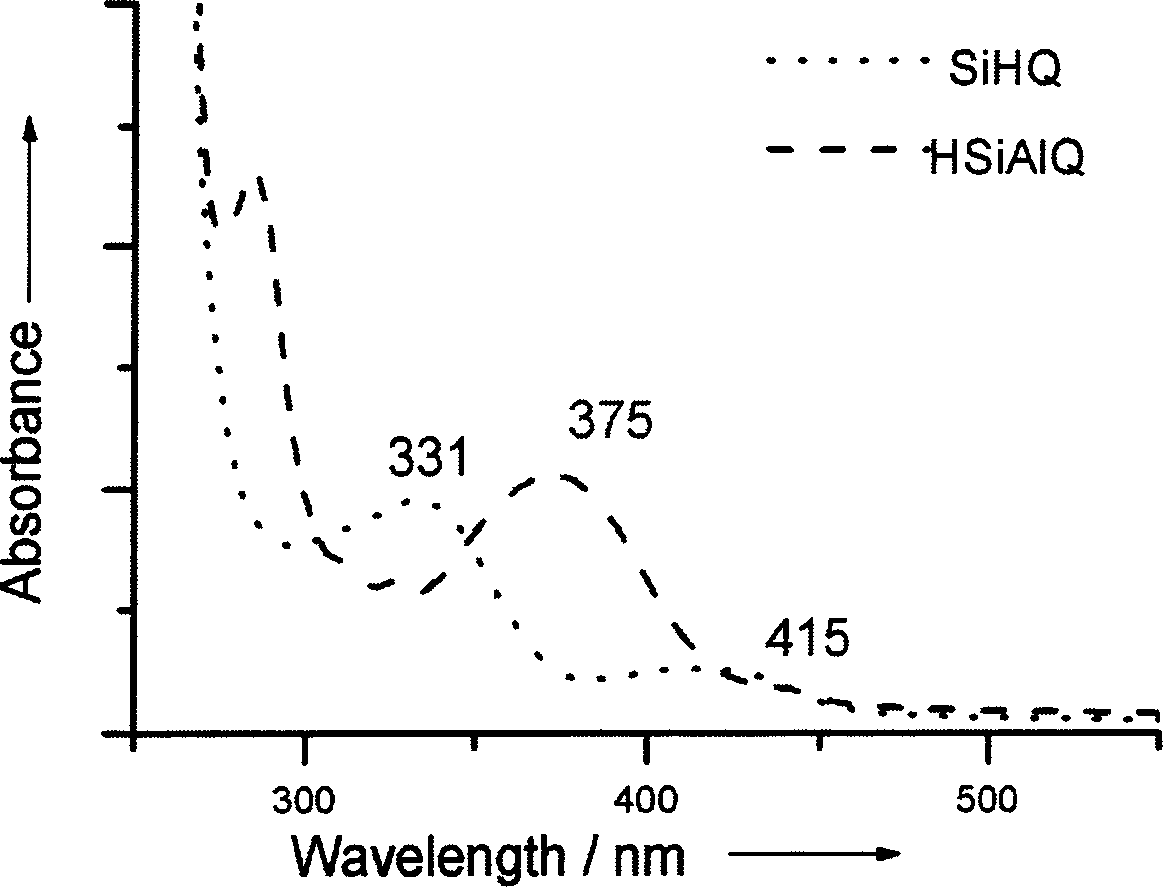

[0023] Through organic synthesis, graft organic functional groups on 8-hydroxyquinoline, and then react with silane coupling agent to generate silylated 8-hydroxyquinoline ligand (SiHQ) and make dimethylformamide (DMF) solution, Add tetraethyl orthosilicate (TEOS), water and aluminum ions, SiHQ: TEOS = 1: 50, and magnetically stir to generate an organic-inorganic composite sol. After the sol is stable, dry and form it to obtain 8-hydroxyquinoline compound Aluminum-silicon oxide organic-inorganic composite luminescent material bulk gel. The material properties are shown in Table 1.

Embodiment 2

[0025] Example 2: The formulation ratio is SiHQ:TEOS=1:10, and the material properties are shown in Table 1.

Embodiment 3

[0026] Example 3: The formulation ratio is SiHQ:TEOS=1:20, and the material properties are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com