Coriolus versicolor strain and method for producing Coriolus versicolor intracellular glycopeptide using the strain

A technology of versicolor versicolor and strains, applied in the direction of fungi, fermentation, etc., which can solve the problems of low yield of glycopeptides in versicolor versicolor, low content of active ingredients, and low mycelium yield, so as to retain activity and improve yield efficiency and reduce extraction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The seed liquid is prepared from the slant culture of the strain CCTCC M204081 through two-stage liquid fermentation culture:

[0049] Incline culture:

[0050] The slant medium (g / l) is potato 200, glucose 10, sucrose 10, yeast powder 0.1, agar 2; after inoculation, culture at 27°C for 5 days;

[0051] Primary and secondary seed cultivation:

[0052] The seed medium (g / l) is glucose 30, sucrose 30, corn flour 21, bran 17, peptone 10, bean cake powder 15, dipotassium hydrogen phosphate 6, magnesium sulfate 0.6; cultivated for 50 hours after inoculation, temperature 28°C, Rotate at 170rpm to obtain seed solution.

Embodiment 2

[0054] Fermentation medium: Each liter medium contains 30g of glucose, 20g of bean cake powder, 6g of peptone, 5g of bran and inorganic salts. 30 liters of full-automatic stainless steel fermenters (produced by Wuxi Sanhai Biochemical Engineering Co., Ltd.), liquid capacity 22L, 121 ℃ of sterilization 25min, after cooling to room temperature, insert the seed liquid of embodiment 1, inoculum size is 10%, stir Speed 200rpm, ventilation 0.8v / v / m, temperature 27℃, tank pressure 0.5kg / cm 2 .

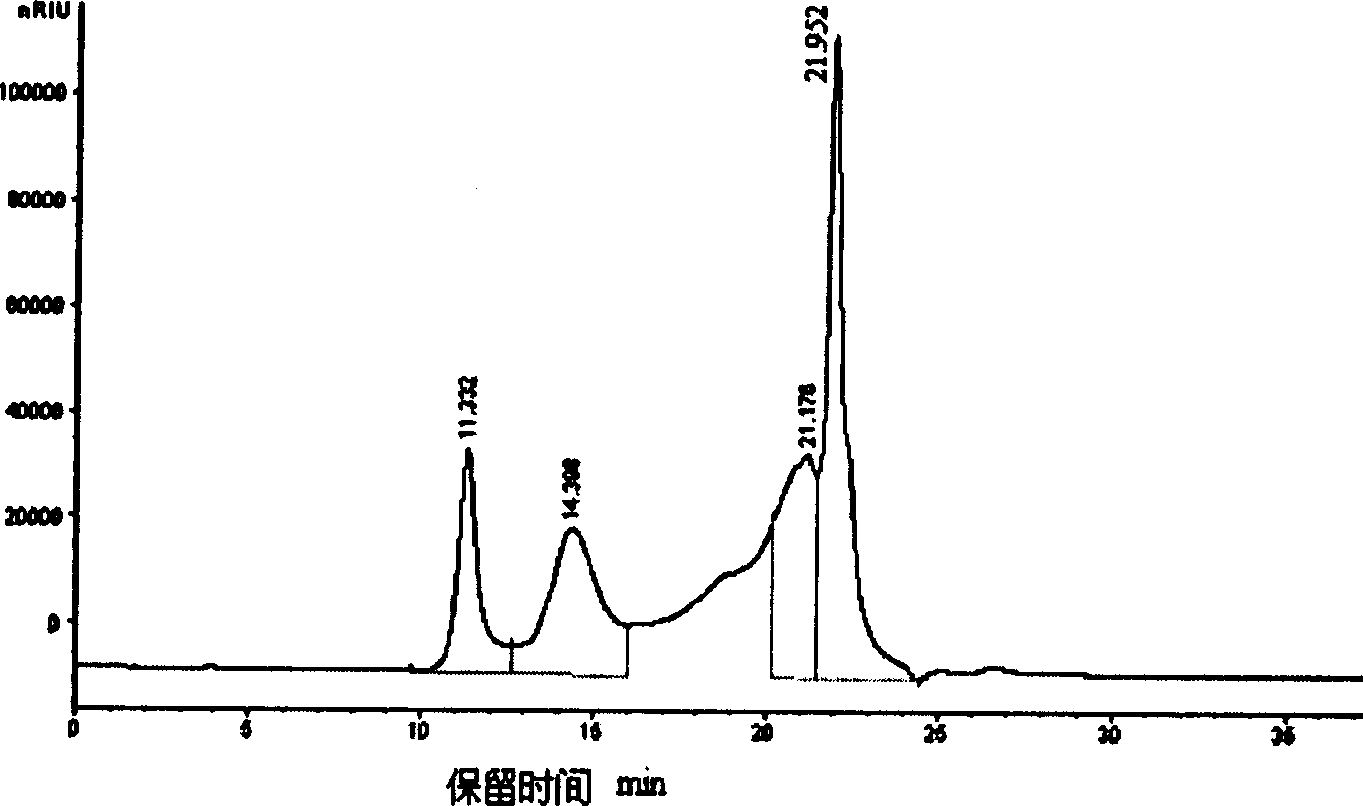

[0055] Fermentation was completed after 4 days of cultivation. The dry weight of the mycelium was 18.50g / l. The mycelium was extracted with broken wall hot water, filtered, concentrated under reduced pressure, and dried by alcohol precipitation to obtain 1.10g / l intracellular glycopeptide. Its total sugar was detected to be 44.57%, and the peptide was 27.92%. It was detected by HPLC, and its peak time was the same as that of the standard product. Other indicators are in line with the nati...

Embodiment 3

[0057] Fermentation medium:

[0058] Each liter of medium contains 30g of glucose, 20g of bean cake powder, 6g of peptone, 5g of bran and inorganic salts. 30-liter automatic stainless steel fermentation tank, liquid volume 20L, inoculum volume 10%, stirring speed 150rpm, ventilation 1v / v / m, temperature 26℃, tank pressure 0.5kg / cm 2 . After 30 hours of fermentation, add 1 L of glucose with a weight concentration of 20%, and at the same time use 0.1N NaOH to control the pH to 5. After 4.5 days of cultivation, the fermentation ends. The dry weight of the mycelium is 28.78g / l, and the mycelium is extracted by broken hot water , filtered, concentrated under reduced pressure, and dried by alcohol precipitation to obtain 2.0g / l intracellular glycopeptide. The total sugar was 55.15% and the peptide was 34.42%. HPLC detection showed that the peak time was the same as that of the standard product, which met the requirements of the national drug Standard WS-XG-021-2002.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com