Manufacturing installation for ice plasm and processing unit for substrates

A technology for a substrate processing device and a manufacturing device, which is applied in the field of particles, and can solve the problems of mixing resin components, metal contamination of substrates, and dissolution of ice particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, best embodiments of the present invention will be described with reference to the drawings.

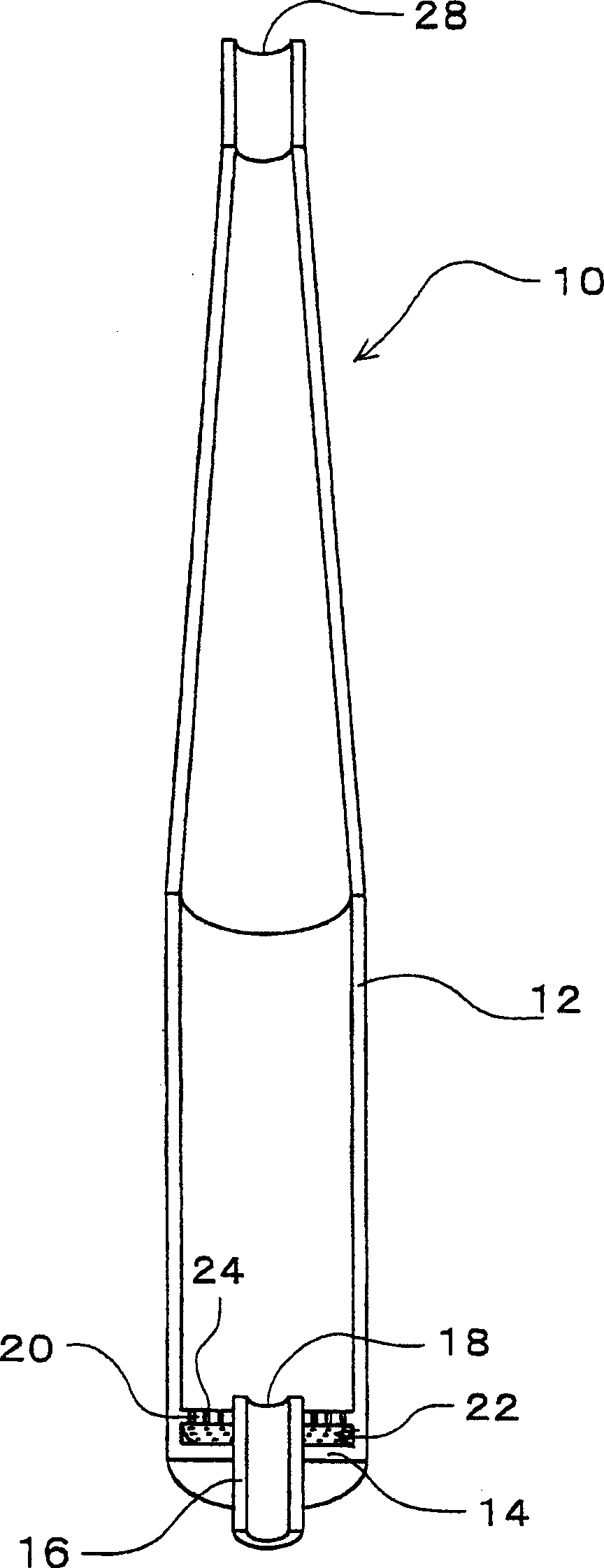

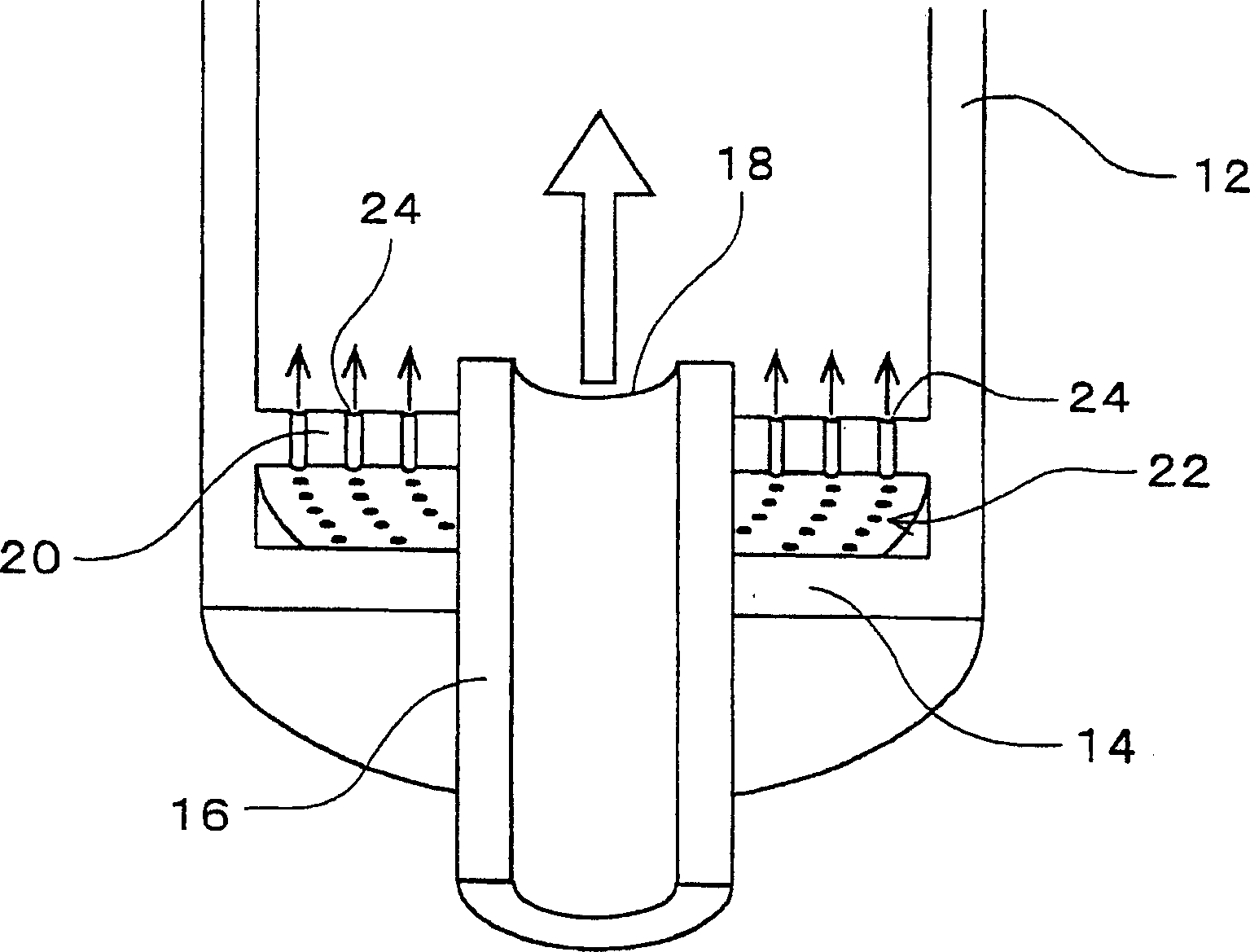

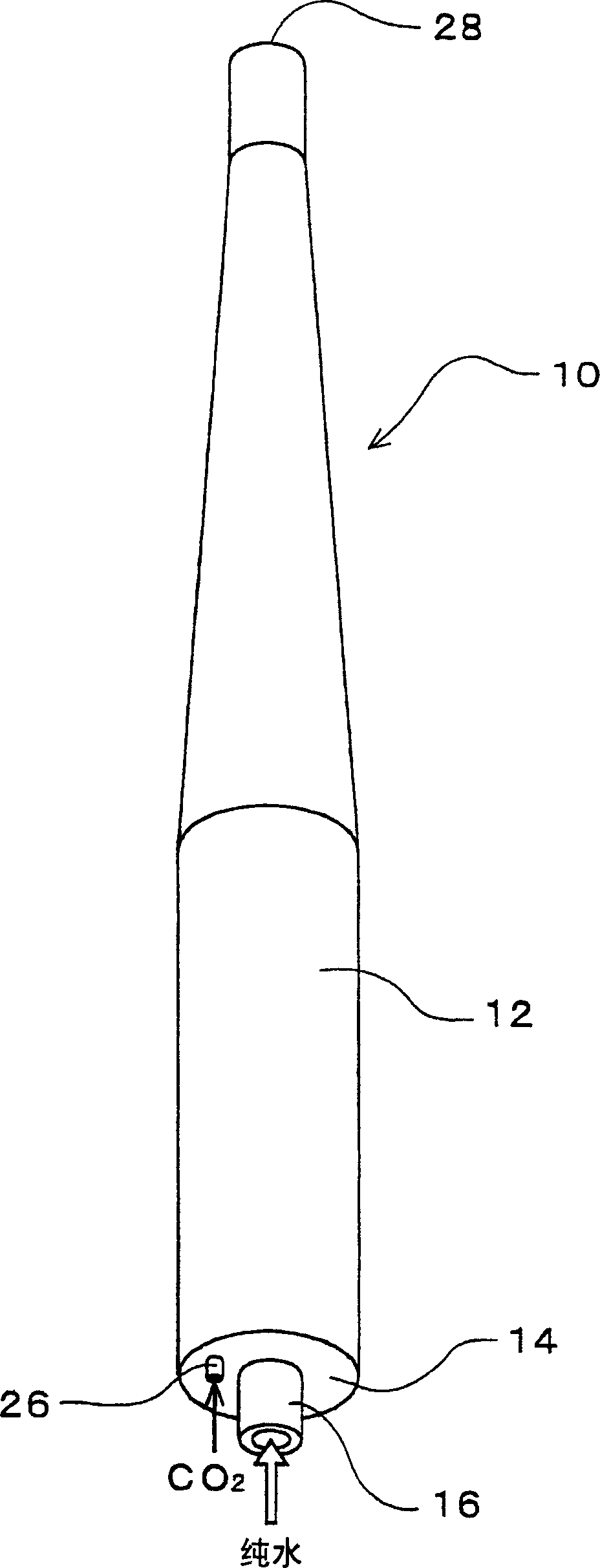

[0038] Figure 1 to Figure 3 , represents an example of an embodiment of the present invention, figure 1 It is a perspective view which shows the state which cut|disconnected the main-body part of the manufacturing apparatus of ice slurry in the longitudinal direction. figure 2 It is a partially enlarged perspective view of the main body section in a longitudinally cut state. image 3 is an external perspective view of the main body.

[0039] This ice slurry production device is a device for producing a treatment liquid (hereinafter referred to as "ice slurry") that dissolves carbon dioxide and contains ice particles, and its main body 10 is formed in an elongated circular tube shape. That is, the main body 10 has a straight pipe 12 formed such that the inner diameter gradually decreases from the lower end to the upper end, and the lower end surface of the stra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com