Anti-scaling and dirty-proof block tower-plate

An anti-fouling and tray technology, applied in the direction of fractionation, etc., can solve the problems of short service life of composite layer or coating, and achieve the effects of reducing the possibility of fouling and clogging of trays, optimizing flow and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

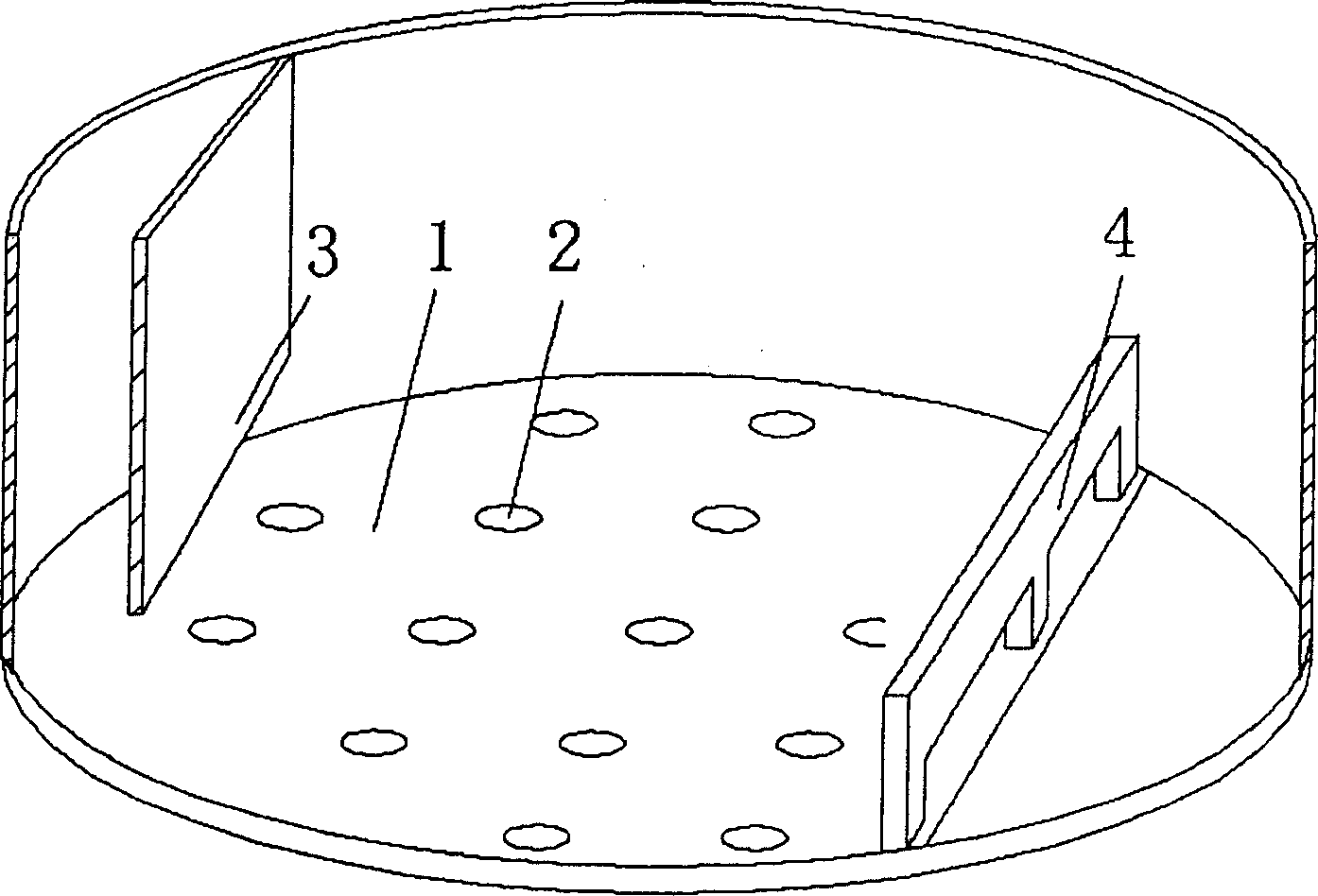

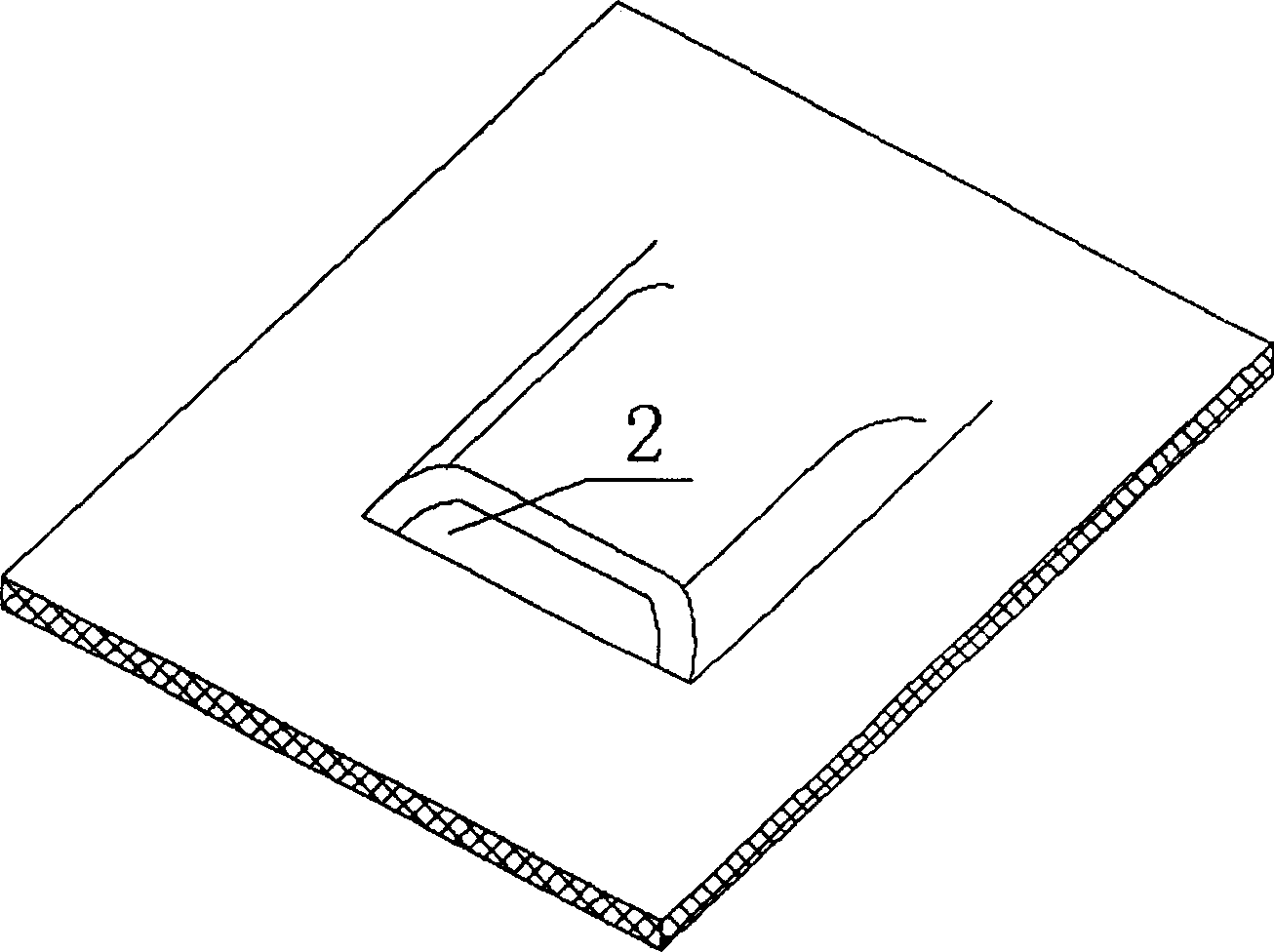

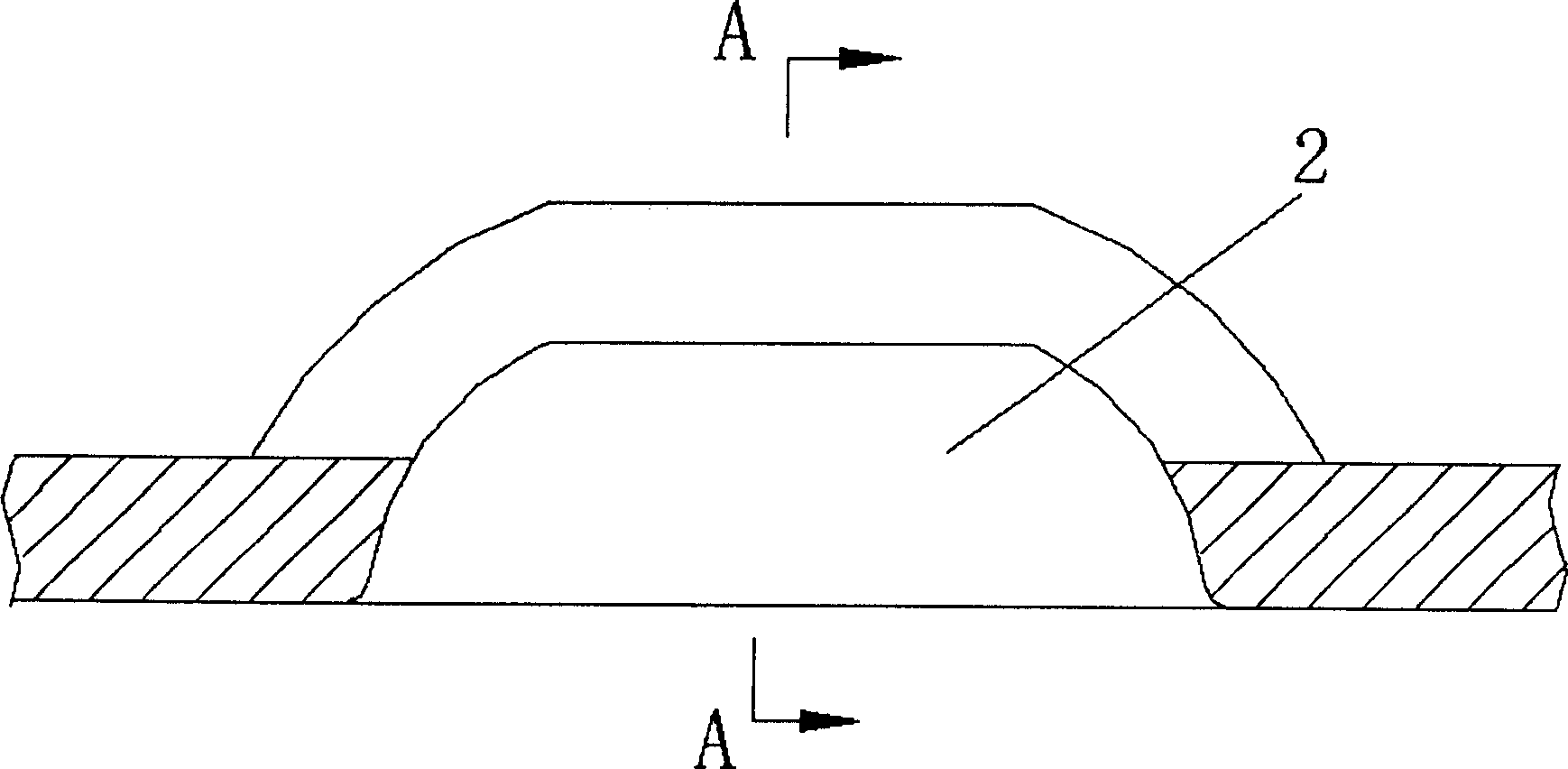

Embodiment 1

[0030] Propylene oxide reactive distillation tower (saponification tower) in a chemical plant, the original diameter of the tower is 2400mm, and the number of trays is 9; single downcomer type, the shape of the downcomer 3 is bow-shaped, and the length of the overflow weir 4 is 1800mm; the traditional large hole is adopted The sieve plate has a hole diameter of 12mm; the material of tray 1 is domestic 304 stainless steel. In the actual production, the blockage of the tray will occur on average in about 10 days. In severe cases, it will be necessary to stop for 5-6 days. The staff will wear protective clothing and masks to clean the tower, which seriously affects the normal production. The environment is extremely harsh and labor-intensive. According to the cleaners, there is a thick layer of hard scale on the surface of the tray below the feed liquid, and the sieve holes are blocked, which is obviously caused by the precipitation and crystallization of a large amount of inorga...

Embodiment 2

[0032]Propylene oxide reactive distillation tower (saponification tower) in a chemical plant, the original diameter of the tower is 3200mm, and the number of trays is 12; single downcomer type, the shape of the downcomer is arc-shaped, and the length of the overflow weir is 3000mm; the traditional large hole is adopted The sieve plate has a hole diameter of 14mm; the material of the plate is 304 stainless steel. In the actual production, the clogging of the trays will occur on average about 30 days, which seriously restricts the production output. According to the maintenance worker, the blockage of the trays is mainly concentrated on the upper and lower trays of the feed liquid inlet. The two trays are different: the lower surface of the upper tray has extremely hard hanging stalactite scaling, and the lower There is a thick layer of hard scale on the upper surface of the tray, and most of the sieve holes on the upper and lower trays are blocked. Adopt the patent of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com