Production of metal zinc powder from zinc dust and zinc dross

A technology for metal zinc and zinc scum, which is applied in the field of solid waste recycling, can solve the problems of unapplied production, shortened anode life, and has not been popularized, and achieves good environmental and social benefits, simple equipment and low price. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

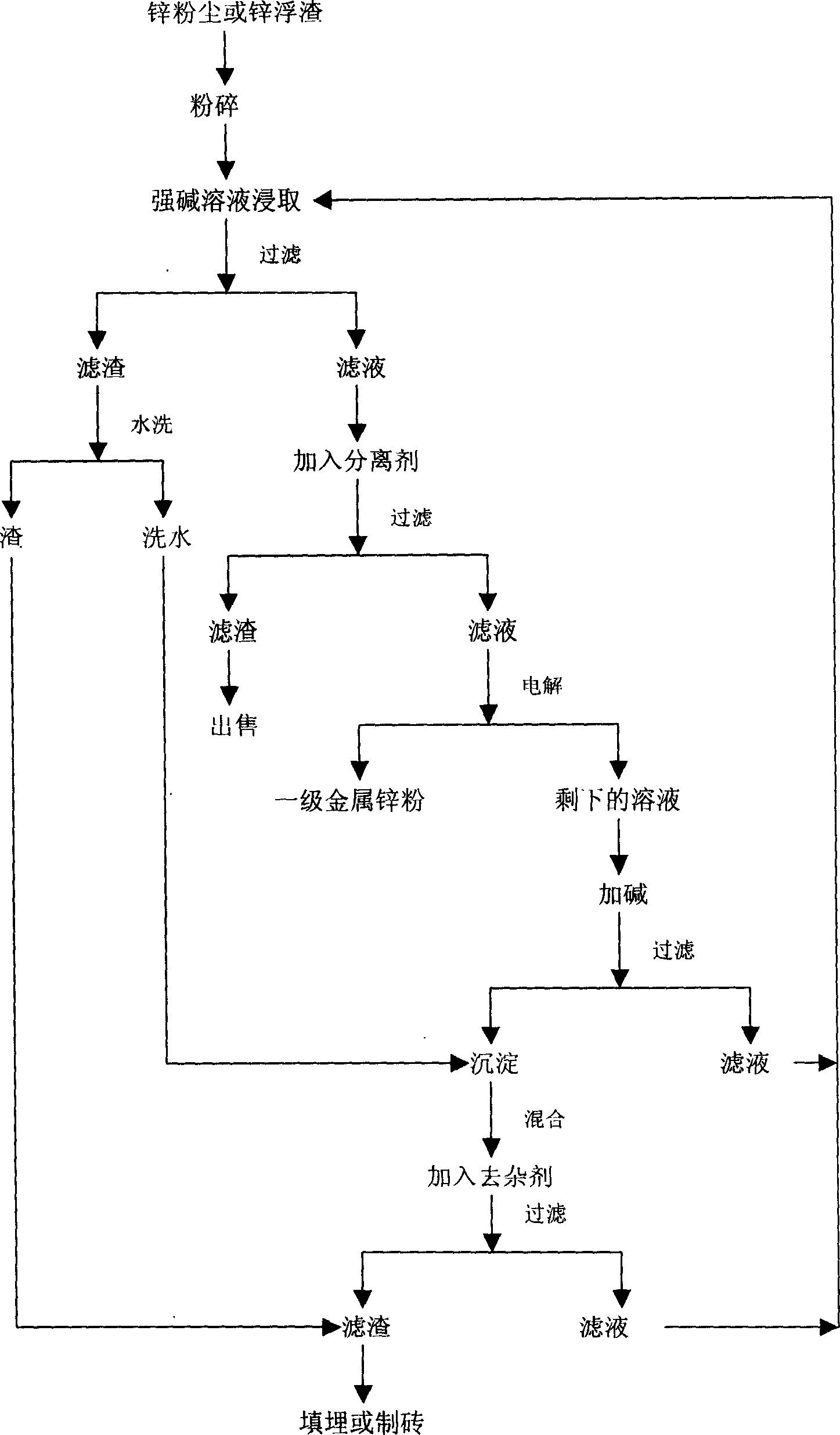

Image

Examples

Embodiment 1

[0019] See attached figure 1 . Using the electric furnace dust of a steelmaking plant as raw material, its chemical composition is shown in Table 1.

[0020] Ingredients

[0021] Put 1t zinc dust into 3-3.5m 3Industrial caustic soda solution, the leaching temperature is controlled at 10-95℃, the concentration of the industrial caustic soda solution is 200-400g / L, and the reaction is carried out for 90 minutes under slow stirring conditions of 120 revolutions / min. Since most metals cannot be dissolved in strong alkaline solutions, the iron, manganese, copper, calcium and other metals in the zinc dust will be precipitated in the filter residue in the form of hydroxides. The filtrate contains only zinc, lead and a small amount of aluminum. The extraction rates of zinc and lead in zinc powder are 95% and 94%, respectively. Filter, wash the filter residue with water, and retain the washing water. A separating agent is added to the filtrate. The separating agent is sodium sulf...

Embodiment 2

[0023] Using zinc scum from a zinc smelter as raw material, its chemical composition is as follows:

[0024] Ingredients

[0025] In zinc dross, zinc is mainly ZnO, and zinc is also ZnS, (CuZn) 5 (SO 4 ) 2 (OH) 6 ·6HO, ZnSO 4 ·2.5H 2 O, Zn 5 (OH) 8 Cl 2 ·2H 2 The formation of O and other compounds exists, and they are all easily soluble in strong alkali solutions. The chlorine in the zinc dross exists in the form of NaCl after alkaline leaching, which is very stable and will not corrode equipment and electrode plates. Crush the zinc dross to 0.5-1mm. Then, leaching with sodium hydroxide solution: 1 ton of zinc scum is immersed in 10 cubic meters of sodium hydroxide solution, and the leaching is stably controlled at 10-95°C, the concentration of sodium hydroxide solution is 350g / L, and the rate is 120 revolutions. After 100 minutes of reaction under slow stirring conditions of / min, the extraction rates of zinc and lead are both 100%. Filter while hot, wash the filter res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com