On-line chromatographic analytical system and use for gas-solid-phase oxidation reactant

An oxidation reaction and chromatographic analysis technology, which is applied to the online chromatographic analysis system of gas-solid phase oxidation reaction products and its application field, can solve the problems of long analysis time, inability to analyze oxygen, errors, etc., and achieve the effect of fast and accurate analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

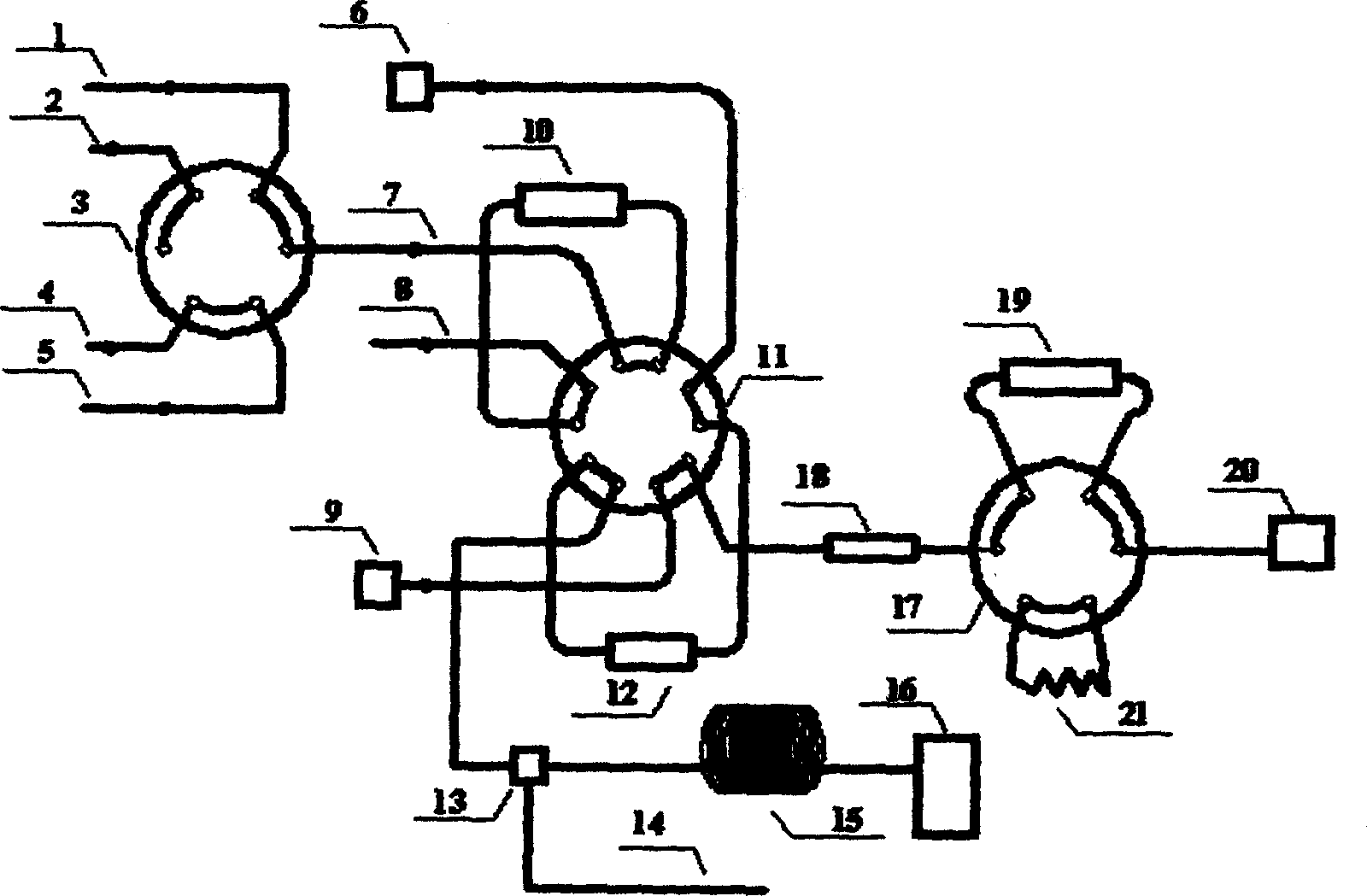

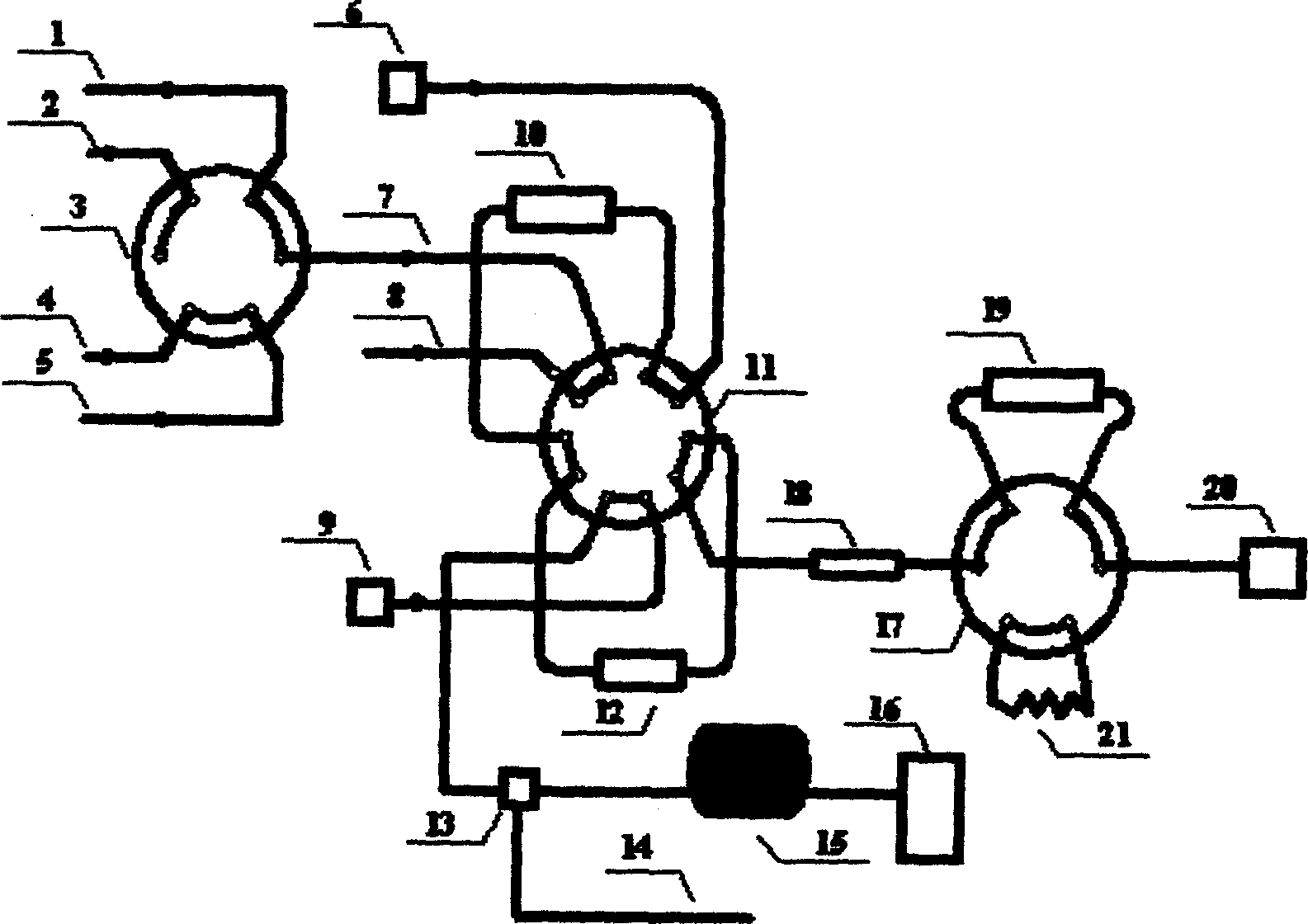

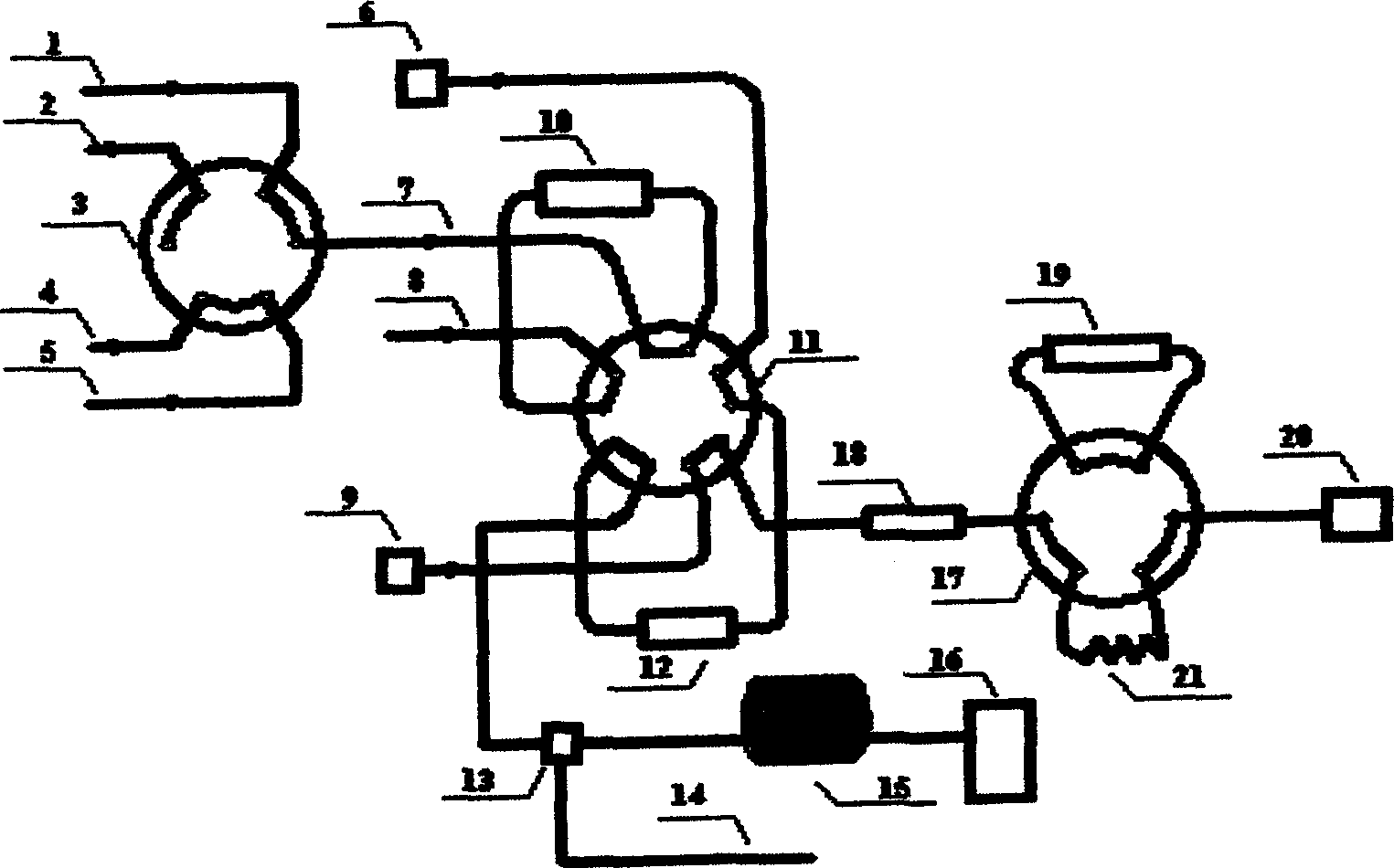

[0023] see Figure 1 ~ Figure 3 . The two-step oxidation of isobutene or tert-butanol to methacrylic acid is a typical complex gas-solid phase oxidation reaction. At this time, isobutene or tert-butanol and air pass through a fixed-bed shell-and-tube reactor equipped with a solid catalyst to undergo an oxidation reaction. The product of this reaction is more complicated, except the unreacted isobutene (i-C 4 ) and deep oxidation products carbon monoxide (CO), carbon dioxide (CO 2 ), there are organic oxidation products such as methacrolein (MAL), methacrylic acid (MAA), acetaldehyde, propionaldehyde, acetone, acrolein, acetic acid, propionic acid and acrylic acid. use figure 1 The shown online analysis system of the present invention analyzes the oxidation product of this reaction, and the composition of the system includes: sample inlet and outlet, two carrier gas flow lines, four chromatographic columns, thermal conductivity detector and hydrogen flame ion chemical dete...

Embodiment 2

[0028] The two-step oxidation of propylene to acrylic acid is also a typical complex gas-solid phase oxidation reaction. Propylene passes through a fixed-bed shell-and-tube reactor equipped with a solid catalyst for oxidation reaction. Oxidation products of this reaction include carbon monoxide, carbon dioxide, propylene, acetaldehyde, propionaldehyde, acetone, acrolein, acetic acid, propionic acid, and acrylic acid, among others. Adopt the online analysis system of the present invention identical with embodiment 1 to analyze the oxidation product of this reaction, chromatographic column 1, chromatographic column 2, chromatographic column 3 and chromatographic column 4 select PEG-20M packed column, Porapak Q packed column respectively , 5A molecular sieve packed column and FFAP capillary column. The qualitative analysis chromatograms of each substance are shown in Figure 5 and 6 , ethanol was selected as the associated substance for quantitative analysis. At the same time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com