Carbon composite material and its preparing method and use

A technology of carbon composite materials and carbon materials, applied in the field of electrochemistry, can solve the problems of poor stability of material batches, incomplete coating, and poor effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] In the preparation method of the carbon composite material of the present invention, step (1) involves impregnation of natural graphite. The natural graphite used in this step is not limited in any way, including but not limited to flaky natural graphite, spherical or potato-shaped natural graphite. The polymers used in this step are free radical polymers or polycondensation polymers, including but not limited to polypropylene, polyethylene, polystyrene, polymethacrylates, polyvinyl chloride, polyacrylonitrile, nitrile rubber , styrene-butadiene rubber, polyphenylene, polynaphthalene, phenolic resin, urea-formaldehyde resin, epoxy resin and their copolymers; the polymer solution used in this step can be aqueous solution, alcohol solution or other organic compounds corresponding to the polymer The solvent solution is preferably an aqueous solution or an ethanol solution in terms of cost; the concentration of the polymer solution is not particularly specified, mainly beca...

Embodiment 1

[0026] 100 g of the carbon composite material coated for the first time obtained in Comparative Example 1 and 100 g of a 20% phenolic resin aqueous solution were stirred and mixed at room temperature for 6 hours, and then dried at 150° C. to remove water. The mixture after water removal was placed in a tube furnace, heat-treated at 800° C. for 12 hours under a nitrogen atmosphere, cooled, and pulverized to obtain a carbon composite material coated for the second time. The composite material can be used as negative electrode material of lithium ion battery.

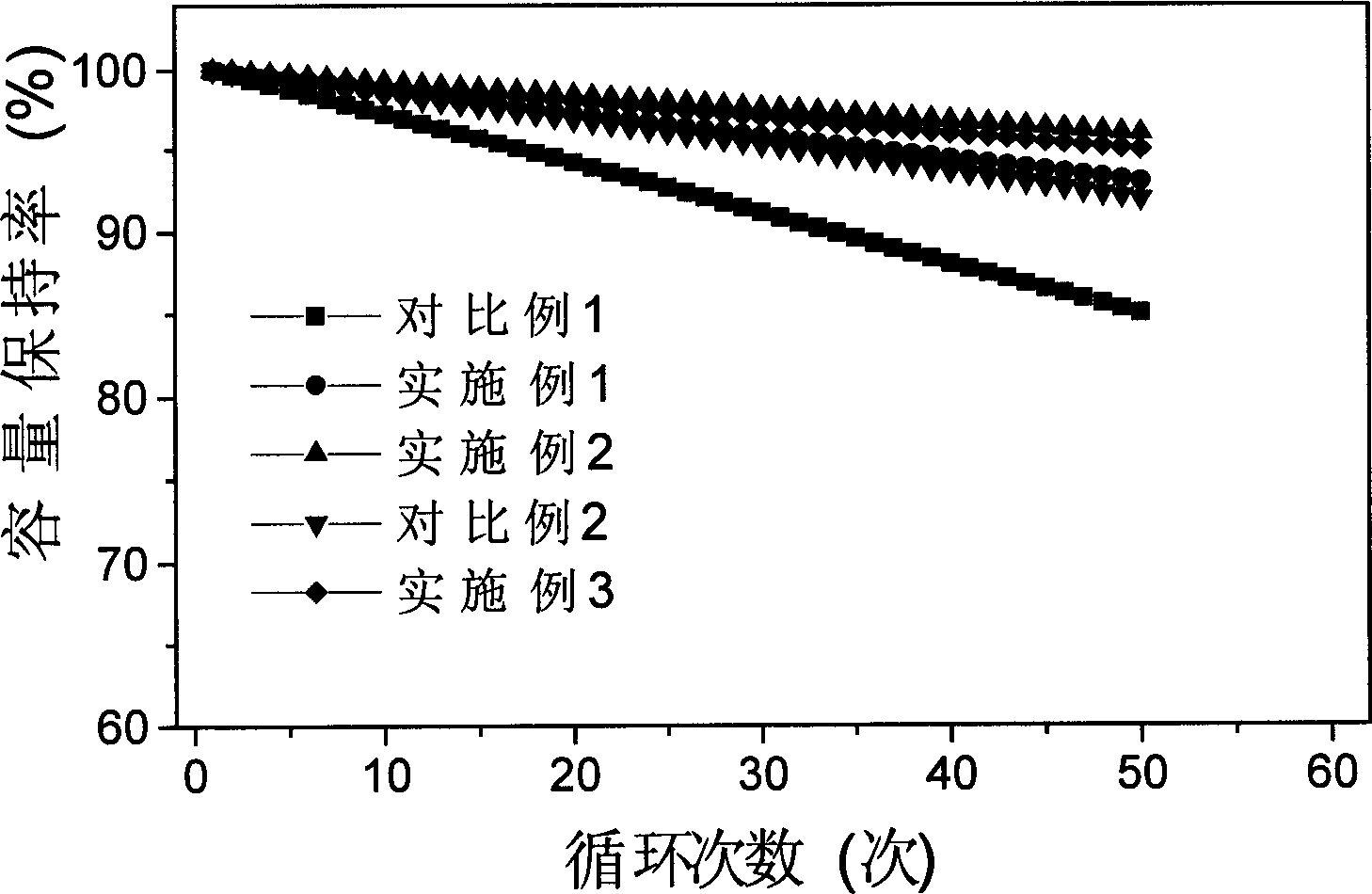

[0027] The preparation of the negative electrode and the testing of its electrochemical performance were the same as those in Comparative Example 1 except that the carbon composite material coated for the second time obtained in this example was used as the negative electrode material. The relationship between capacity retention and cycle number is shown in figure 1 . The figure shows that the capacity retention was 93% af...

Embodiment 2

[0029] 100 g of the carbon composite material coated for the first time obtained in Comparative Example 1 and 100 g of a 20% phenolic resin aqueous solution were stirred and mixed at room temperature for 6 hours, and then dried at 150° C. to remove water. The mixture after water removal was placed in a tube furnace, heat-treated at 800° C. for 12 hours under a nitrogen atmosphere, cooled, and pulverized to obtain a carbon composite material coated for the second time. The composite material can be used as negative electrode material of lithium ion battery.

[0030] The preparation of the negative electrode and the testing of its electrochemical performance were the same as those in Comparative Example 1 except that the carbon composite material coated for the second time obtained in this example was used as the negative electrode material. The relationship between capacity retention and cycle number is shown in figure 1 . The graph shows that the capacity retention was 96% a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap