Method for preparing polyimide/silicon dioxide nanometer hybridized film

A technology of silica and polyimide, which is applied in the field of synthesis and preparation of organic-inorganic hybrid materials, can solve problems such as poor dispersion, unsatisfactory improvement in mechanical and optical properties of hybrid films, and large particles. Achieve the effects of improving compatibility, improving optical transmission performance, and increasing the degree of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

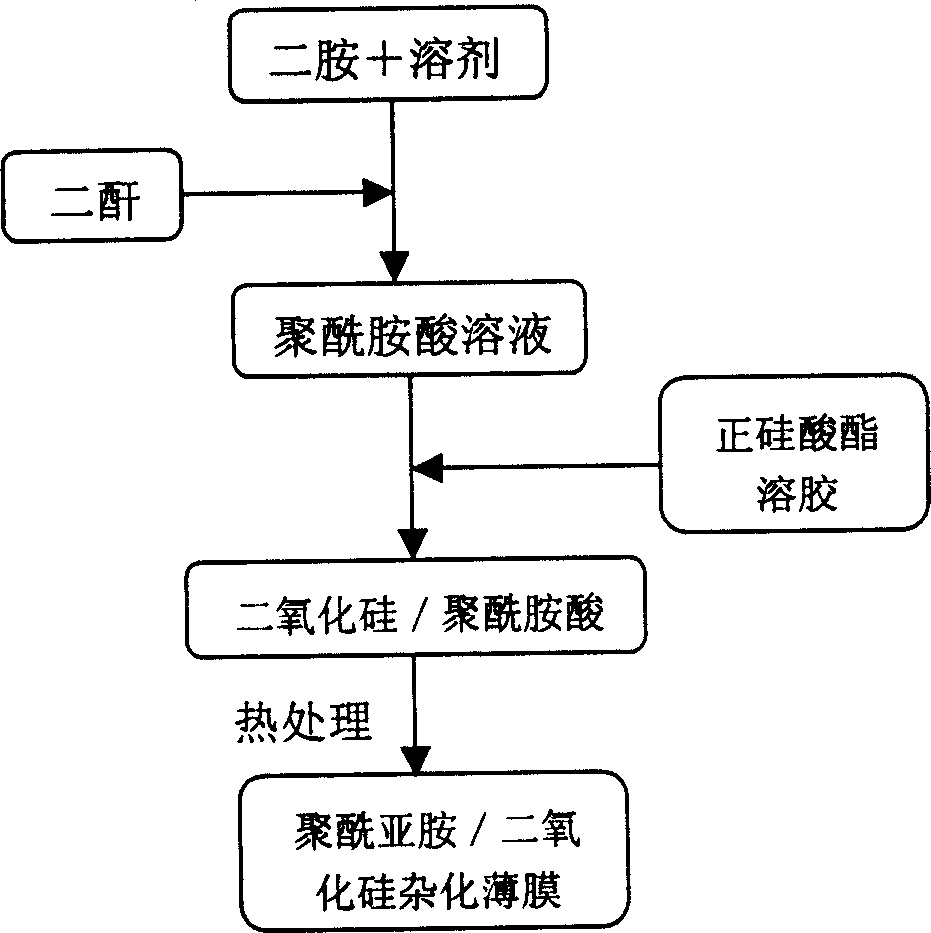

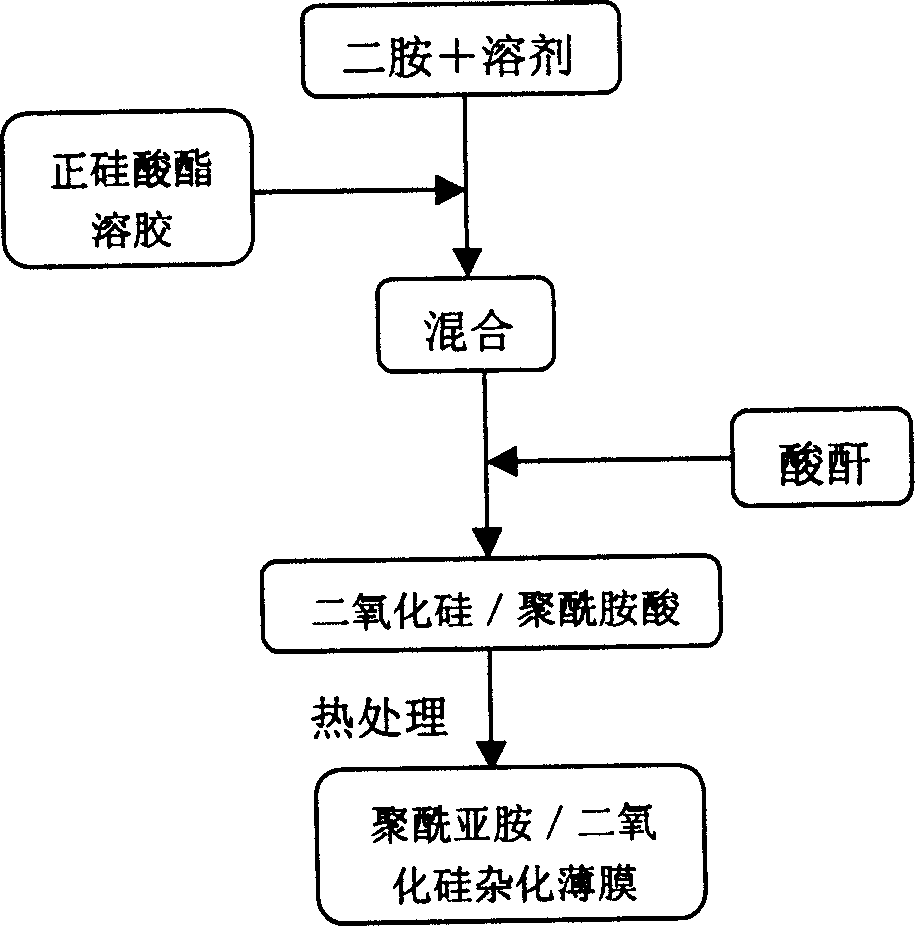

Method used

Image

Examples

Embodiment 1

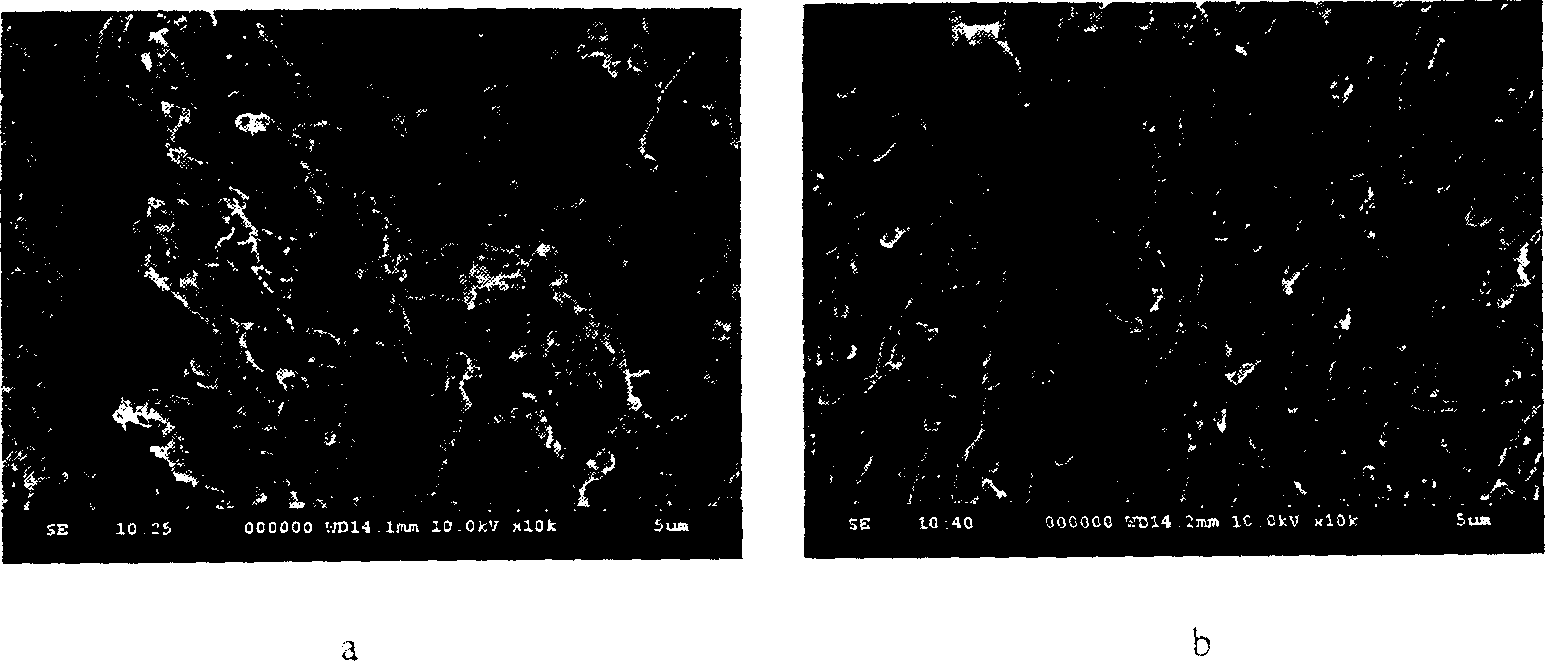

[0039] in N 2(purity is 99.999%) under protection, in a clean three-necked flask, add 7.0084g 4,4'-diaminodiphenyl ether (ODA) (0.035mol) and 83.0gN, N'-dimethylacetamide (DMAC ), stirred for 10 min, and the mixture became clear; 4.04 g of tetraethyl orthosilicate (TEOS) (0.0194 mol) was added to 12.8 g of ethanol, and stirred evenly. 0.078 mol of deionized water, 0.0008 mol of concentrated hydrochloric acid and 0.002 mol of γ-aminopropyltriethoxysilane (GOTMS) were added dropwise, and stirred for 30 min. Form sol; Add this sol slowly in the DMAc solution of ODA, stir 2h, form uniform solution; Get 0.035mol pyromellitic dianhydride (PMDA), be divided into 3 parts, every 30min join in the above-mentioned solution, in After stirring at room temperature for 4 h, a homogeneous solution was obtained. Then apply a film on a glass plate by scraping, and carry out imidization treatment by gradually increasing the temperature—baking at 80, 100, 120, 150, 180, 240, and 270°C for 1 hou...

Embodiment 2

[0044] in N 2 (purity is 99.999%) under protection, in a clean three-necked flask, add 7.0084g 4,4'-diaminodiphenyl ether (ODA) (0.035mol) and 83.0g N, N'-dimethylacetamide ( DMAC), stirred for 10 min, and the mixture became clear; 1.44 g of tetraethyl orthosilicate (TEOS) (0.0069 mol) was added to 4.58 g of ethanol, and stirred evenly. Add 0.0276mol of deionized water, 0.00028mol of concentrated hydrochloric acid and 0.0007mol of γ-aminopropyltriethoxysilane (GOTMS) dropwise, and stir for 30min to form a sol; slowly add the sol to the DMAc solution of ODA, and stir for 2h , to form a homogeneous solution; take 0.035mol pyromellitic dianhydride (PMDA), divide it into 3 parts, add it to the above solution every 30min, and stir at room temperature for 4h to obtain a homogeneous solution. Then apply a film on a glass plate by scraping, and carry out imidization treatment by gradually increasing the temperature—baking at 80, 100, 120, 150, 180, 240, and 270°C for 1 hour to obtain...

Embodiment 3

[0048] in N 2 (purity is 99.999%) under protection, in a clean three-necked flask, add 7.0084g 4,4'-diaminodiphenyl ether (ODA) (0.035mol) and 83.0g N, N'-dimethylacetamide ( DMAC), stirred for 10 min, and the mixture became clear; 2.45 g of tetraethyl orthosilicate (TEOS) (0.0118 mol) was added to 7.74 g of ethanol, and stirred evenly. Add 0.047mol of deionized water, 0.00047mol of concentrated hydrochloric acid and 0.0012mol of γ-aminopropyltriethoxysilane (GOTMS) dropwise, and stir for 30min to form a sol; slowly add the sol to the DMAc solution of ODA, and stir for 2h , to form a homogeneous solution; take 0.035mol pyromellitic dianhydride (PMDA), divide it into 3 parts, add it to the above solution every 30min, and stir at room temperature for 4h to obtain a homogeneous solution. Then apply a film on a glass plate by scraping, and carry out imidization treatment by gradually increasing the temperature—baking at 80, 100, 120, 150, 180, 240, and 270°C for 1 hour to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com