Prepn. of expanding halide-free fire-retardant and products thereof

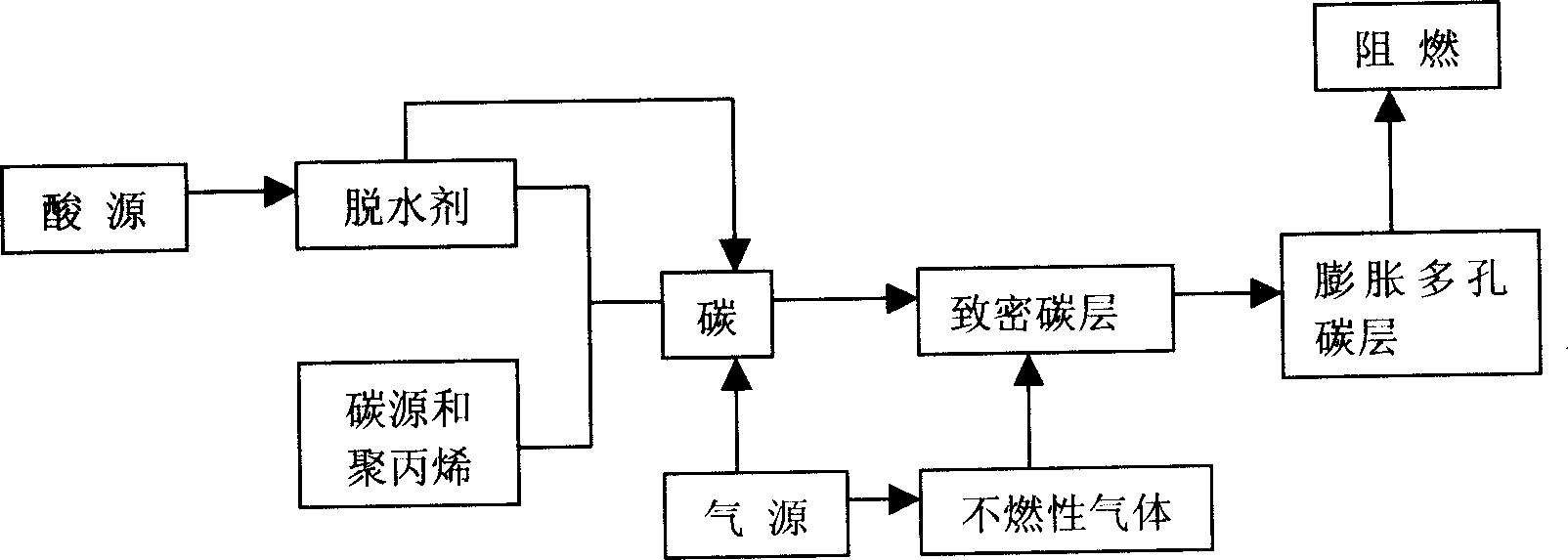

The technology of an intumescent flame retardant and a phase transfer catalyst is applied in the field of flame retardant preparation, and can solve the problems of not easy to be affected by coloration and decomposition mechanical properties, easy to color decomposition mechanical properties, and unstable flame retardant effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

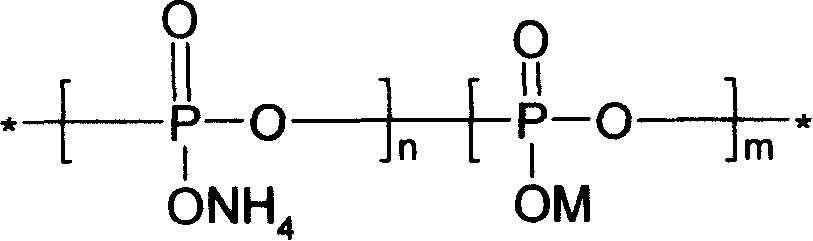

[0161] 1. Add phosphorus pentoxide (P 2 o 5 Content ≥ 98%) 4347 grams, add diammonium hydrogen phosphate (ammonium dihydrogen phosphate content ≥ 95%) 3631.6 grams simultaneously, stir and heat, and pass 20 minutes of 0.1 liters / minute of ammonia, and keep the ammonia pressure at 0.2Mpa. When it rises to 250°C, it becomes a viscous syrupy liquid, and when kept at 250°C for 1 hour, it becomes a white solid powder.

[0162] 2. Under stirring, pass 0.2 L / min of nitrogen gas, cool to 50° C., pulverize and sieve to obtain compound (III).

[0163] 3. At -5°C, add 1000 grams of (III) to 3 liters of 85% ethanol, stir for 30 minutes, add 0.2 grams of benzyltriphenylphosphine hydroxide activated with pyridine, and add 230 grams of it evenly under stirring The nitrogen-containing triazine polymer was reacted for 3 hours, filtered, dried, and pulverized to obtain 1217 grams of an expandable halogen-free flame retardant. The yield was 98.94%. The water solubility is 0.24g / 100g water, a...

Embodiment 2

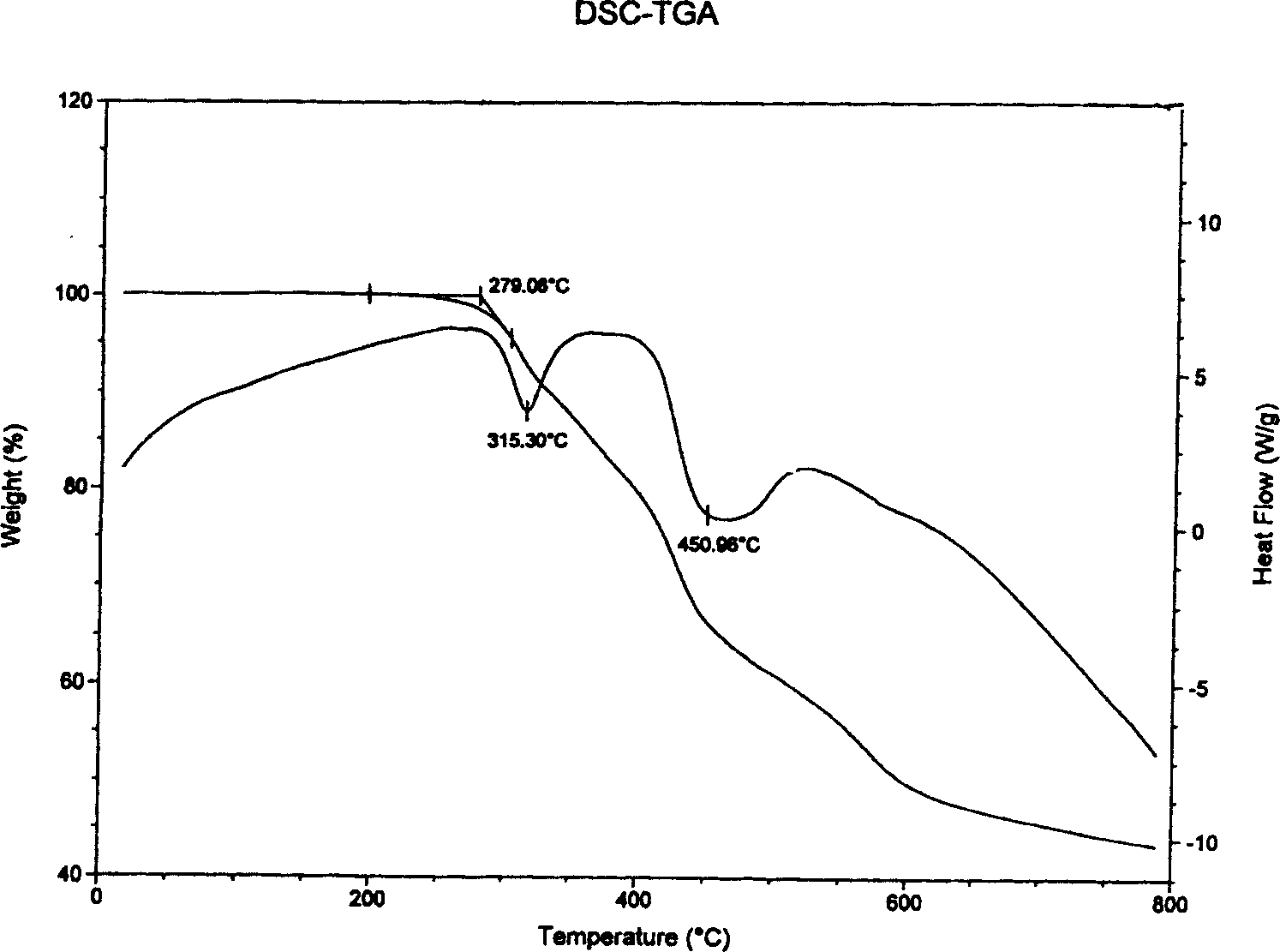

[0165] At -5°C, add 1000 grams of (III) to 3 liters of 85% ethanol, stir for 30 minutes, add 0.2 grams of benzyltriphenylphosphine hydroxide activated with pyridine, and add 26 grams of morphine evenly under stirring , 78 grams of melamine and 45 piperazine, reacted for 2 hours, filtered, dried, and pulverized to obtain 1068 grams of expandable halogen-free flame retardant, with a yield of 92.95%, water solubility of 0.63g / 100g water, and TGA thermal decomposition temperature of 210.56 ℃.

Embodiment 3

[0167] At -5°C, add 1000 grams of (III) to 3 liters of 85% ethanol, stir for 30 minutes, add 0.2 grams of benzyltriphenylphosphine hydroxide activated with pyridine, and evenly add 120 grams of nitrogen-containing The triazine polymer was reacted for 3 hours, filtered, dried and pulverized to obtain 1110 g of expandable halogen-free flame retardant with a yield of 99.10%. Water solubility is 0.45g / 100g water, TGA thermal decomposition temperature is 254.25℃

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com