Porous, laminated, tri-dimensional multiple-grade structure tissue stent material and its preparation method

A technology of tissue scaffolding and three-dimensional space, which can be applied in the fields of coating, medical science, prosthesis, etc., and can solve problems such as unsatisfactory treatment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

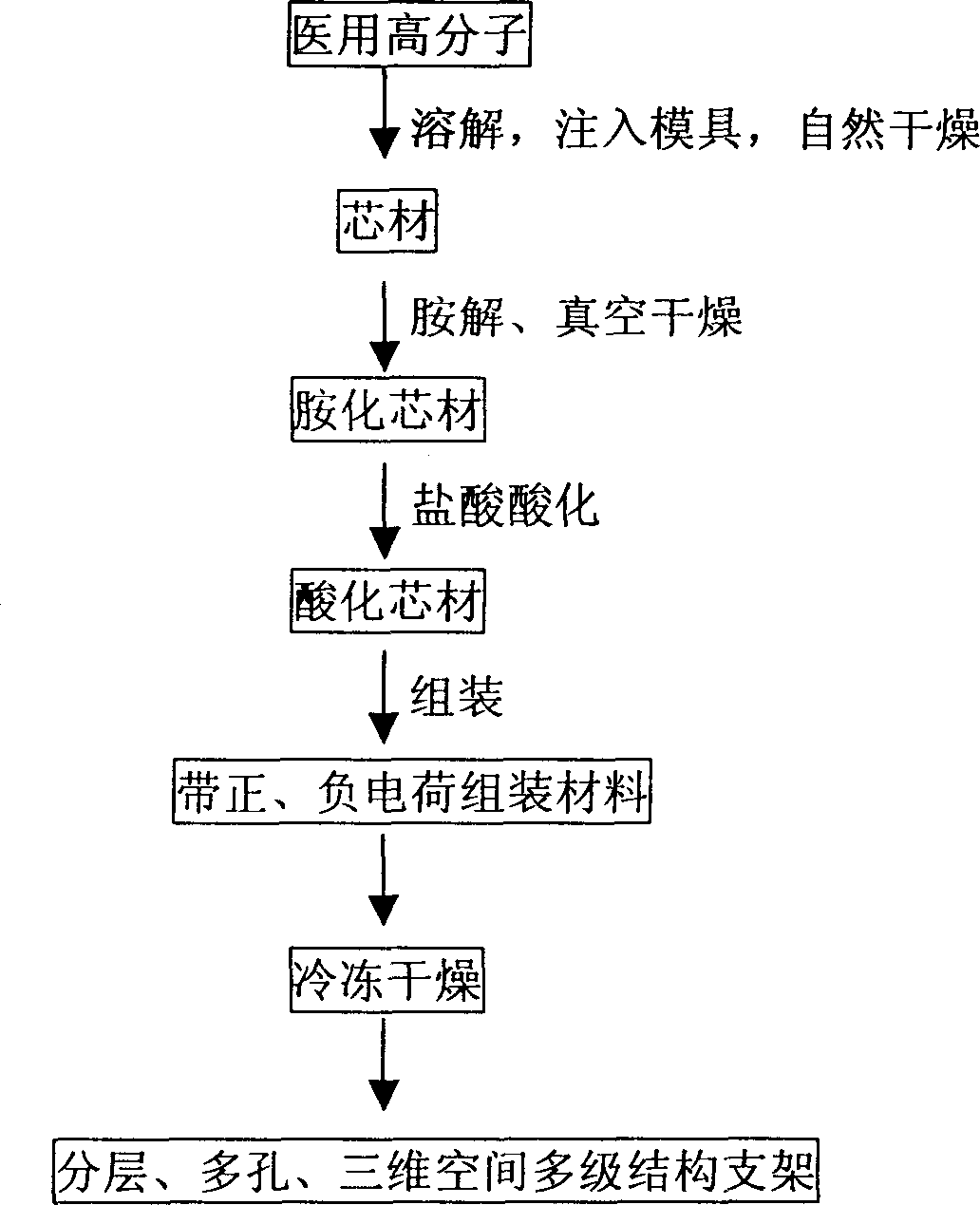

Method used

Image

Examples

Embodiment 1

[0035] 1. Preparation of Scaffold Materials

[0036] 1. Preparation of core material: Dissolve 3 grams of polylactic acid with a weight average molecular weight of 30,000 in 10 milliliters of 1,4-dioxane, inject it into the mold, dry it at room temperature for 24 hours, remove the mold, and transfer it to a vacuum oven ( 20°C) to dry to constant weight, immerse in 1:1 ethanol-water to remove grease and impurities, and fully rinse with water;

[0037] ②Amination reaction: Immerse the above core material in 0.07 g / ml hexamethylenediamine-isopropanol, react at 37°C for 2 hours, rinse with water to remove unreacted hexamethylenediamine, and dry in a vacuum oven at 20°C until constant weight;

[0038] ③ Acidification reaction: Acidify the aminolytic PDLLA core material in 0.02 mol / L hydrochloric acid solution for 1 hour at room temperature, and rinse with a large amount of three-distilled water to remove the adsorbed hydrochloric acid;

[0039] ④Layer-by-layer electrostatic self-...

Embodiment 2

[0045] The same method and steps as in Example 1, but the core material adopts polyglycolic acid (molecular weight 120,000), and the self-assembled material adopts chondroitin sulfate and chitosan-collagen mixture for material preparation, and the number of assembled layers is 20 layers, and -70 ℃ freezer.

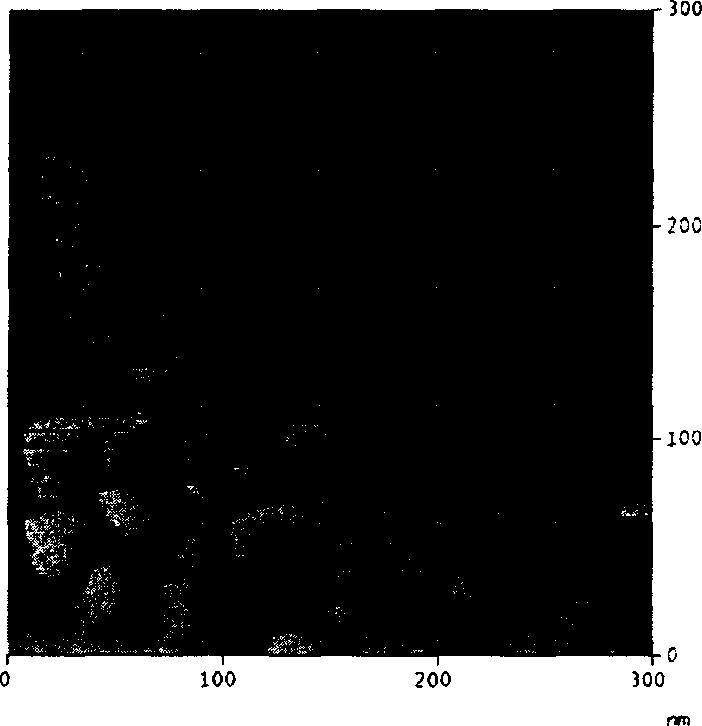

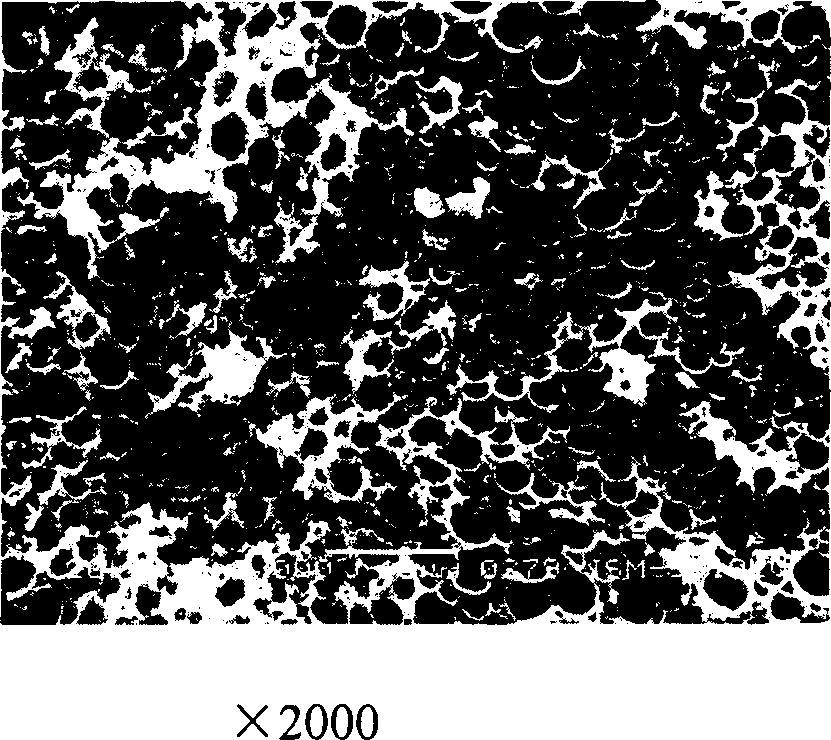

[0046] The cross-section of the conduit observed by the atomic force microscope has an obvious nano-scale layered structure, each layer has a uniform pore distribution, the pores between the layers are connected, and the pore size changes in grades. After being implanted in the body, the material degrades over time. According to the in vitro experiment, the material swelled in 15 days, the shape was complete in 2 months, and the pH value of the solution changed slightly.

[0047] The scanning electron microscope observed that the pore diameter of the inner layer was about 3 nanometers, and the outer layer was about 15 microns; the atomic force microscope observed that the...

Embodiment 3

[0049] The same method and steps as in Example 1, but the core material is polycaprolactone, and the self-assembled material is prepared from a mixture of chondroitin sulfate and chitosan-collagen. The number of assembled layers is 200 layers, and it is frozen in a -70°C refrigerator.

[0050] The cross-section of the conduit observed by the atomic force microscope has an obvious nano-scale layered structure, each layer has a uniform pore distribution, the pores between the layers are connected, and the pore size changes in grades. After being implanted in the body, the material degrades over time. According to the in vitro experiment, the material swelled in 15 days, the shape was complete in 2 months, and the pH value of the solution changed slightly.

[0051] The scanning electron microscope observed that the pore diameter of the inner layer was about 3 nanometers, and the outer layer was about 3500 nanometers; the atomic force microscope observed that the cross-section of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com