Catalyst for preparing ethene ethyl benzene from ethene and benzene in dry gas, preparation method and application thereof

A kind of catalyst, the technology of ethylbenzene, be used in the catalyst field of producing ethylbenzene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

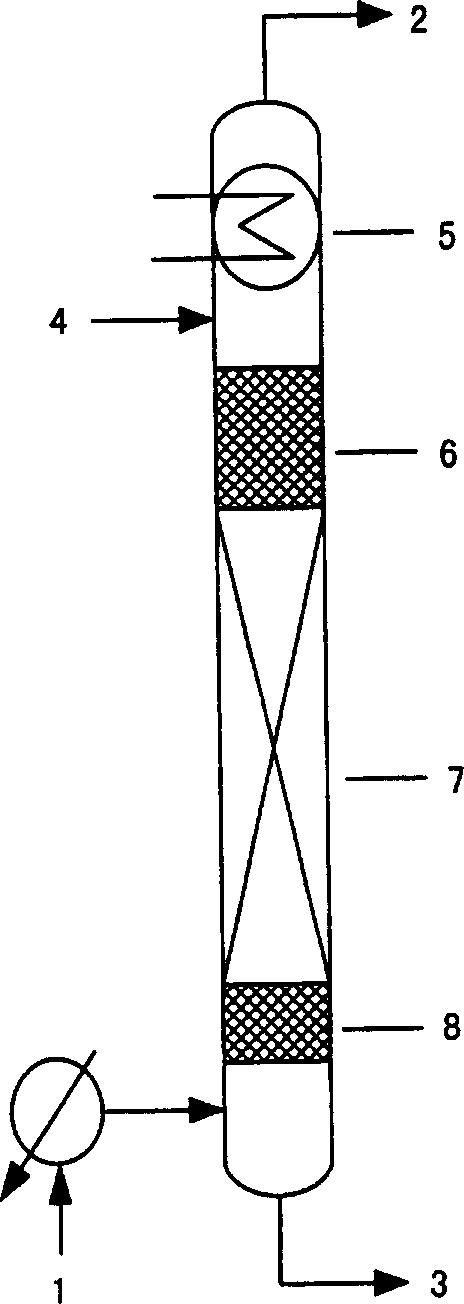

Image

Examples

Embodiment 1

[0044] Weigh 120g NaY molecular sieve (produced by Dalian Chemical Synthesis Factory), SiO 2 / Al 2 O 3 The molar ratio is 5.0, the grain size is 500nm, and 1200 ml of 0.8N ammonium nitrate aqueous solution is added, exchanged at 96 °C for 2 hours, repeated twice, then filtered and washed, and dried at 105 °C for 24 hours to obtain NH 4 NaY-1, relative crystallinity 96%, unit cell parameter 2.465nm, Na 2 O weight content 2.20%.

[0045] will NH 4 NaY-1 was placed in a stainless steel sealed container, the temperature was increased at a rate of 5 °C / min, and the temperature was increased to 590 °C, using NH 4 The pressure generated by NaY-1 itself is maintained at a pressure of 0.11MPa (gauge pressure) for 3.5 hours, and the system is lowered to room temperature. Weigh 100 g of the molecular sieve after the above hydrothermal treatment, add 1000 ml of 2.0N concentration of ammonium nitrate aqueous solution, add HNO 3 77g of aqueous solution with a weight concentration of 3...

Embodiment 2

[0047] Weigh 120g NaY molecular sieve (produced by Dalian Chemical Synthesis Factory), SiO 2 / Al 2 O 3 The molar ratio is 4.8, the grain size is 250nm, the exchange conditions are the same as those in Example 1, and only 0.8N concentration of NH is used instead. 4 Cl aqueous solution replaces ammonium nitrate solution to produce NH 4 NaY-2, relative crystallinity 96%, unit cell parameter 2.463nm, Na 2 O weight content 2.05%.

[0048] will NH 4 NaY-2 was placed in a stainless steel sealed container, the temperature was increased at a rate of 4°C / min, the temperature was raised to 585°C, and the system was maintained at a pressure of 0.10 MPa (gauge pressure) for 3.0 hours and then lowered to room temperature. Weigh 100g of the molecular sieve after the above hydrothermal treatment, add 1.8N concentration NH 4 1000 ml of Cl aqueous solution, add 45 g of HCl weight concentration of 35% aqueous solution, exchange treatment at 95°C for 2.5 hours, repeat the exchange twice, fi...

Embodiment 3

[0050] Weigh 120g NaY molecular sieve (produced by Dalian Chemical Synthesis Factory), SiO 2 / Al 2 O 3 The molar ratio was 4.9, the grain size was 100 nm, and the exchange conditions were the same as those in Example 1, and NH was obtained 4 NaY-3, relative crystallinity 95%, unit cell parameter 2.462nm, Na 2 O weight content 1.97%.

[0051] will NH 4 NaY-3 was placed in a stainless steel sealed container, the temperature was increased at a rate of 4°C / min, and the temperature was increased to 580°C. The system was maintained at a pressure of 0.09MPa (gauge pressure) for 3.0 hours and then lowered to room temperature. Weigh 100g of the molecular sieve after the above hydrothermal treatment, add 2.0N concentration NH 4 NO 3 Solution 1000ml, plus HNO 3 The weight concentration is 64g of a 30% aqueous solution, exchanged at 94°C for 2.2 hours, repeated twice, filtered and washed, and dried at 110°C for 24 hours to obtain DHY-3 with a relative crystallinity of 93% and a uni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com