Vegetable stem preservation method

A technology of plant straw and preservation method, which is applied in the direction of plant preservation, botany equipment and method, application, etc., can solve problems such as drawing on the experience of straw preservation, and achieve the goal of improving the industrial processing value of ethanol, saving a large amount, and saving less cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

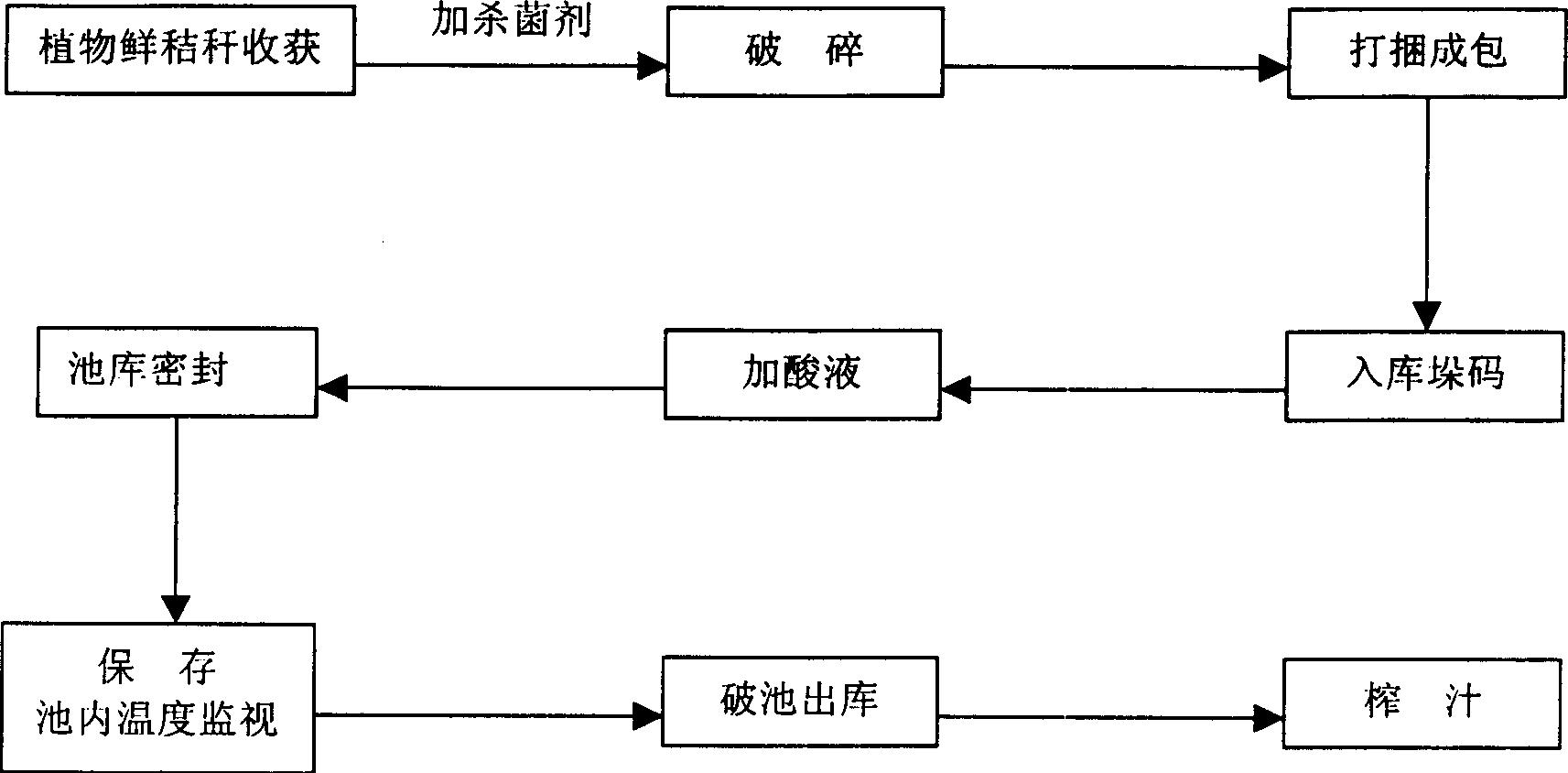

Method used

Image

Examples

Embodiment 1

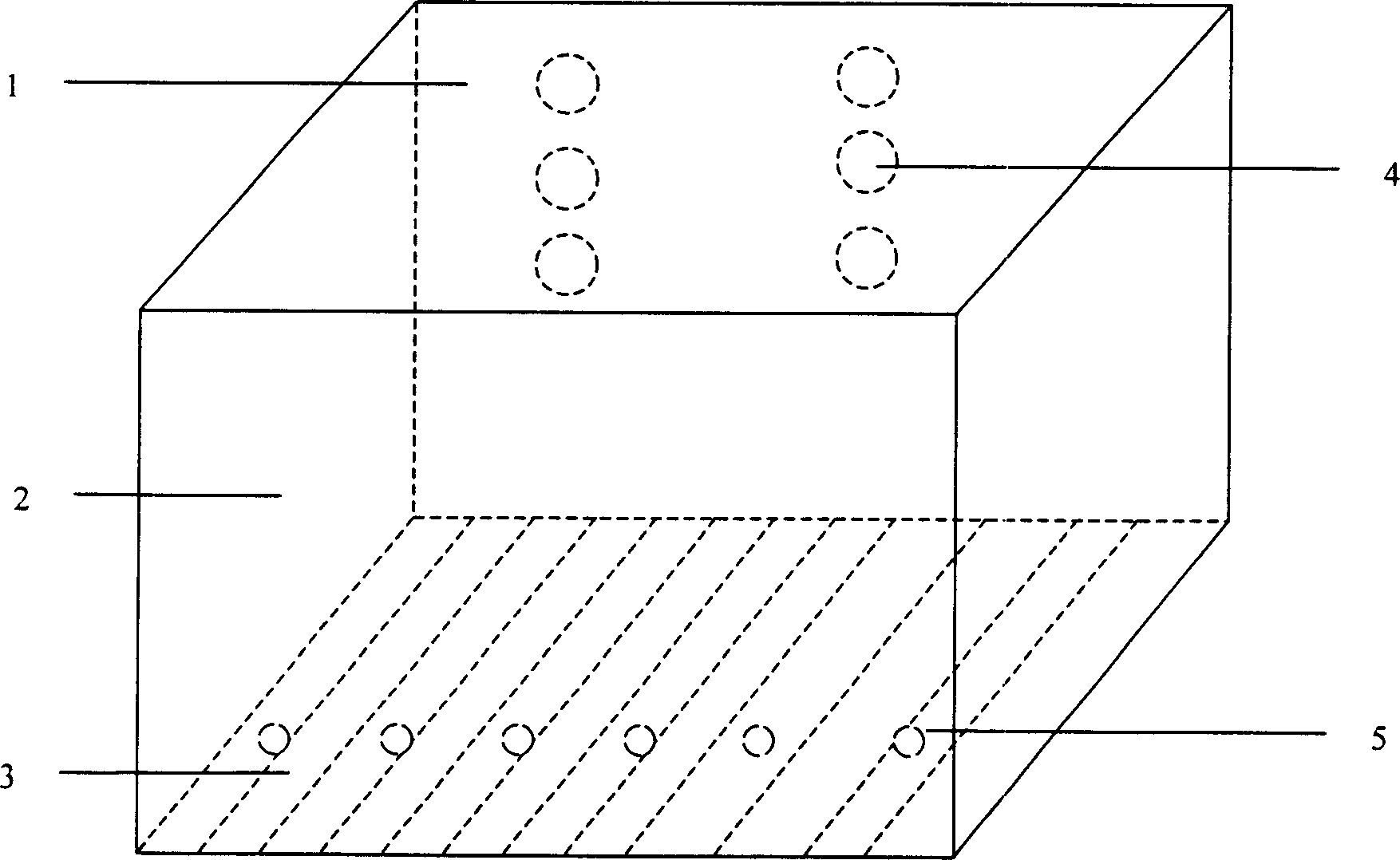

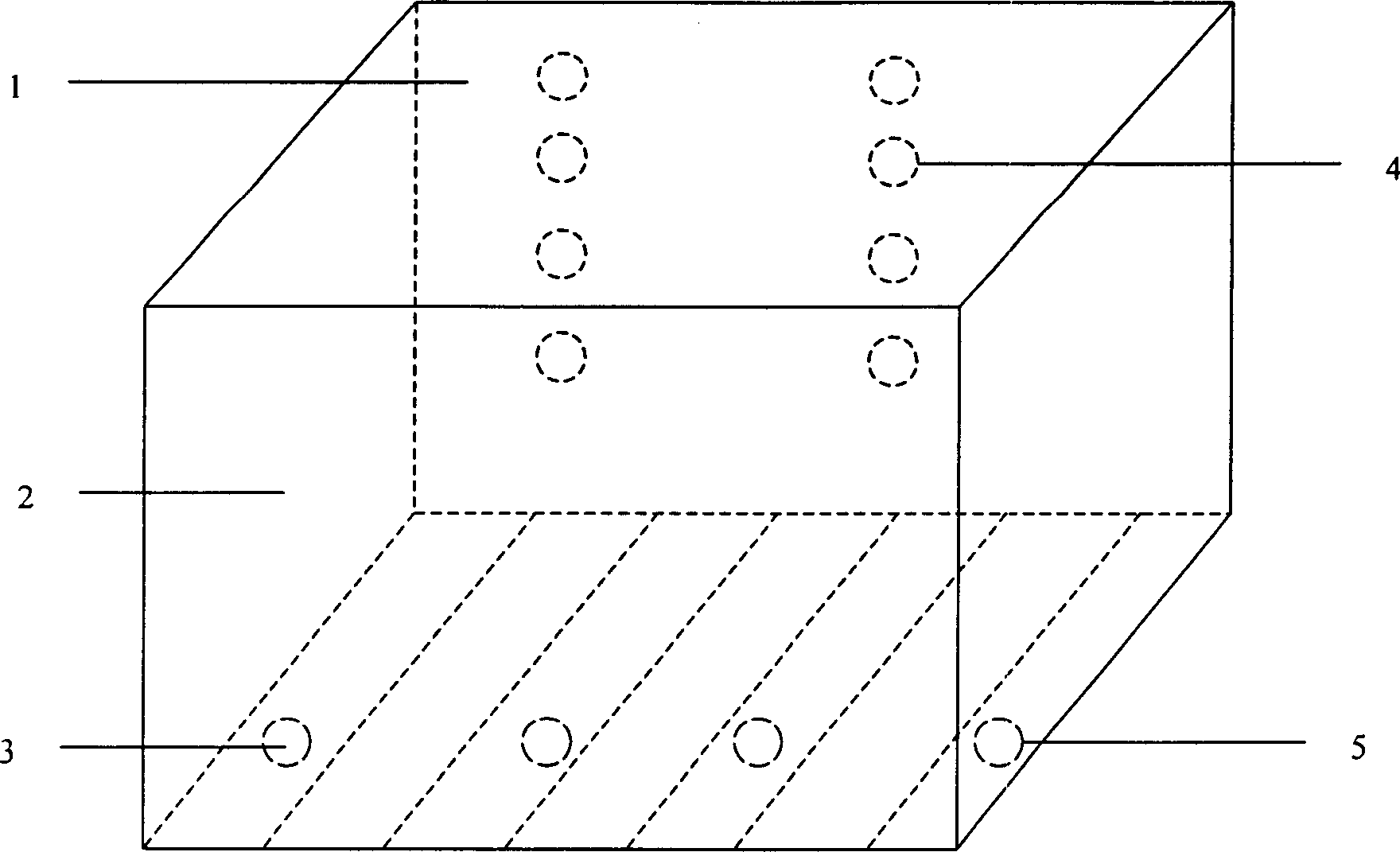

[0062] Dig a ground pool such as 20m long, 10m wide and 10m deep on the ground (such as Figure II ), use reinforced concrete to build the bottom of the pool and the walls of the pool. The filtrate tank is pre-built at the bottom of the pool, and the filtrate tank cannot be blocked by straw bales. The infusion tube is preset in the tank and leads from the wall of the pool. Inject fluid into the reservoir from outside the reservoir. One wall of the pool wall is provided with a sleeve for connecting the temperature sensing probe. The sleeve has a connection line for the temperature sensing probe, and the liquid can be drawn out from the pool or injected from the outside of the pool. The four walls of the pool are 50-100cm above the ground. Epoxy resin is used for the anti-corrosion and anti-leakage treatment of the pool wall, bottom and pool interior. The inner volume of the pool is about 1900m 3 .

[0063] A closed valve is provided at the outlet of the filtrate infusion t...

Embodiment 2

[0098] 1. Preservation material: mature corn stalks.

[0099] moisture

Ash and others

25%-40%

20%-30%

3%-8%

6%-14%

5%-10%

4%-7%

[0100] It can be seen from Table 2-2 that the fresh corn stalks after maturity still contain a large amount of fermentable sugars, but after the fresh corn stalks are cut and dried naturally or matured and air-dried in the field, a large amount of fermentable sugars will be lost . After 100kg of fresh straw is dried, only 45-55kg of dry straw will be obtained. The chemical composition of this dry stalk is as table 2-3

[0101] Table 2-2 Chemical composition of dry corn stalks

[0102] moisture

Ash and others

8%-15%

50%-60%

5%-10%

2%-5%

4%-8%

8%-17%

[0103] From fresh straw to dry straw, the fermentable sugar...

Embodiment 3

[0125] 1. Preservation material: sugar cane.

[0126] The method provided by the invention is also applicable to the preservation of fermentable sugar in sugarcane stalks, so as to improve the economic benefit of producing ethanol from sugarcane.

[0127] 2. Save the pool library.

[0128] In this example, a cylindrical pool is used, and a ground pool with a diameter of 20m is dug underground, and the pool wall and bottom are tightly paved (welded) with 10mm thick plastic plates. The filtrate tank is pre-built at the bottom of the pool, and the filtrate tank cannot be blocked by straw bales. The infusion tube is preset in the tank and leads from the wall of the pool. Inject fluid into the reservoir from outside the reservoir. One wall of the pool wall is provided with a sleeve for connecting the temperature sensing probe. The sleeve has a connection line for the temperature sensing probe, and the liquid can be drawn out from the pool or injected from the outside of the pool....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com