Q-modulation semiconductor laser with electric absorption grating structure

A grating structure and laser technology, applied in semiconductor lasers, lasers, laser parts, etc., can solve the problems of high cost, complex production, and difficult to integrate, and achieve the effect of high extinction ratio, high speed, and improved modulation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below according to the drawings and embodiments.

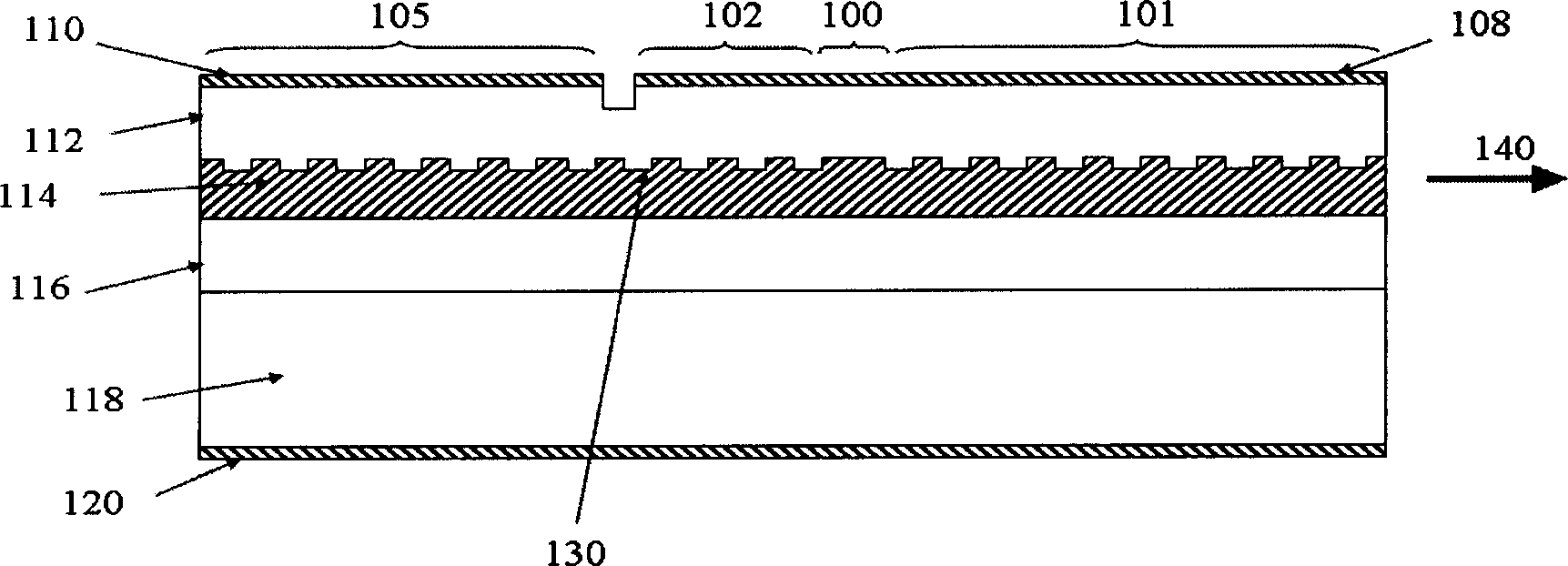

[0032] The Q-modulated semiconductor laser of the present invention has many different specific structures, wherein the laser resonator can be based on a distributed feedback (DFB) grating or a distributed Bragg reflection (DBR) grating with a phase shift, respectively.

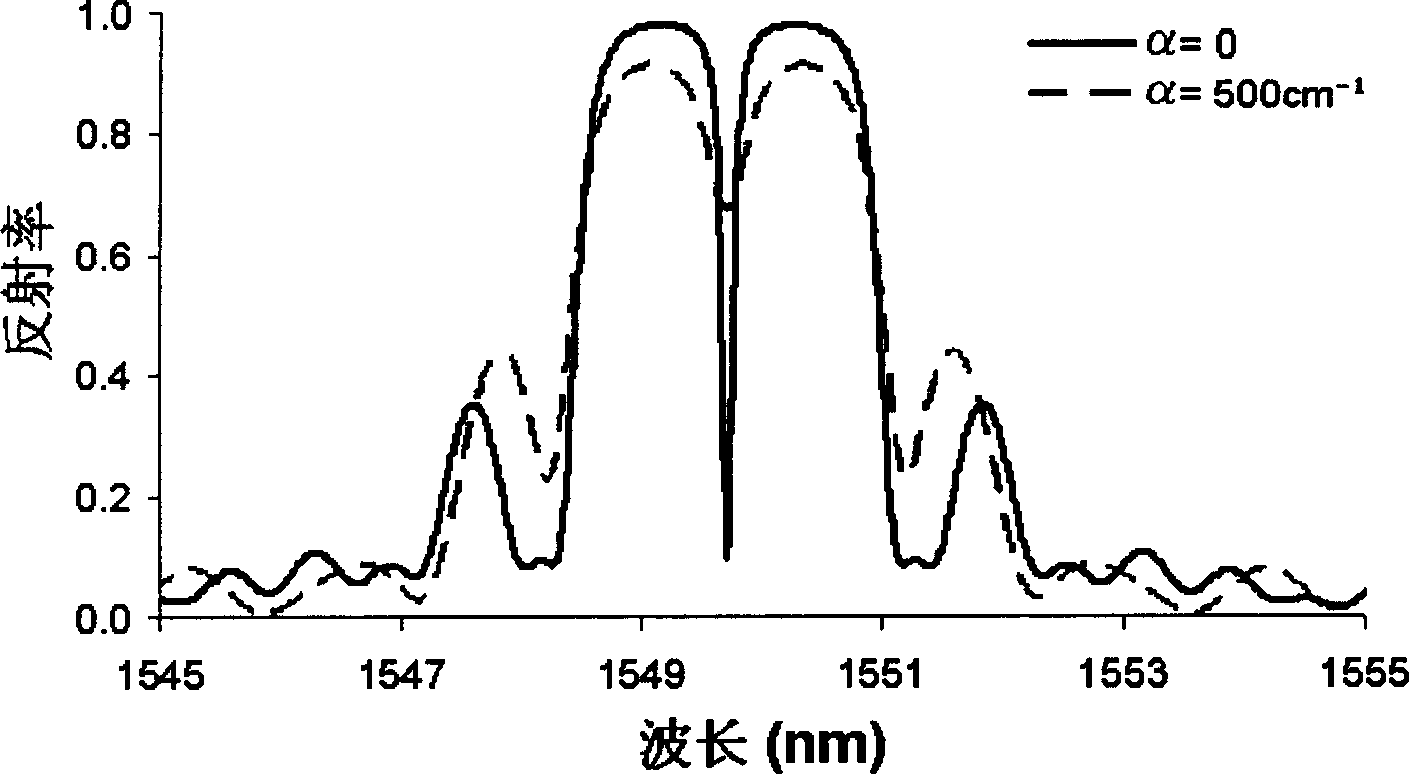

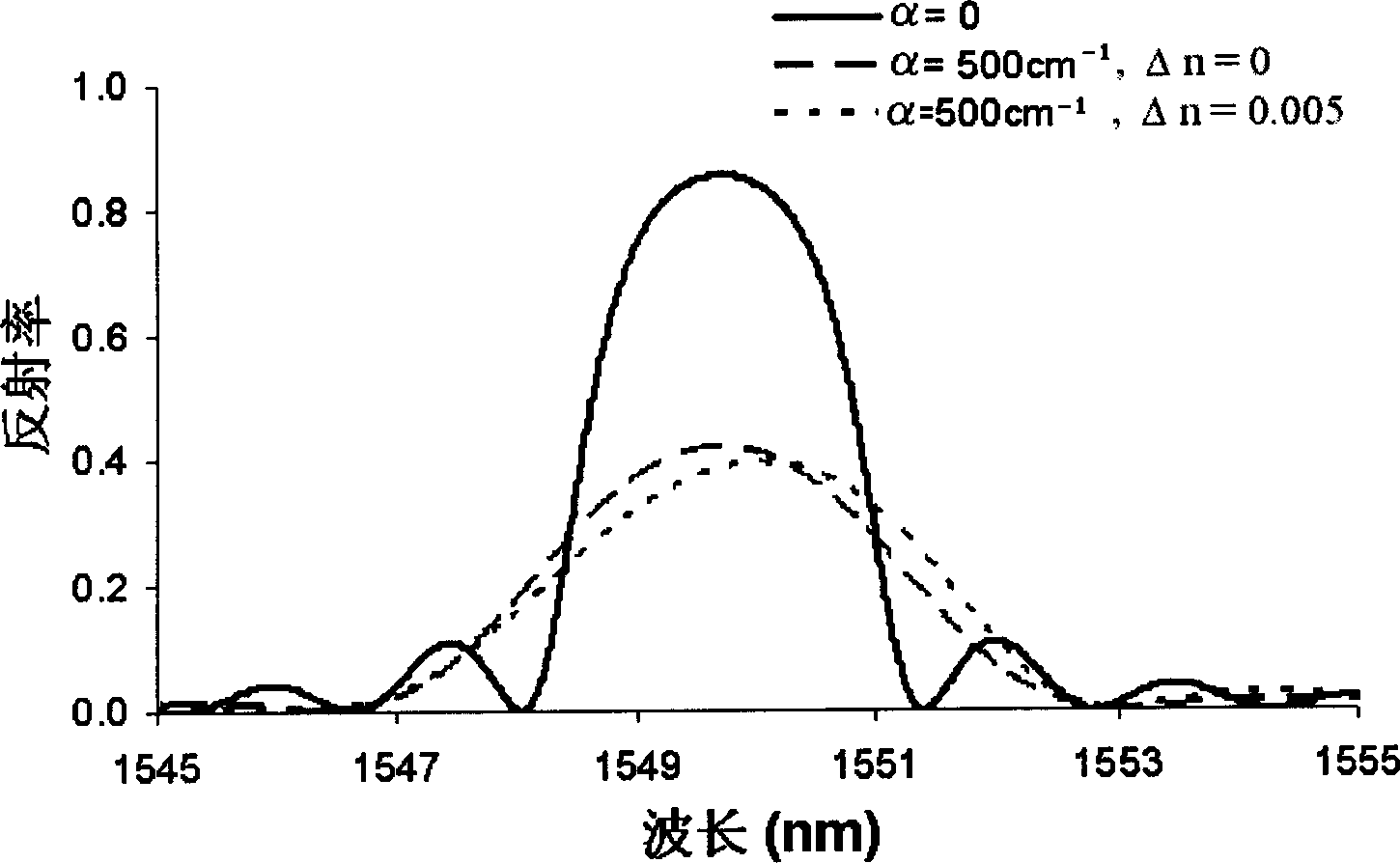

[0033] The Q factor or quality factor of a laser resonator is used to measure how much light from the laser gain medium is fed back through the optical resonator. A high Q factor means that the light travels in the resonator and suffers less loss every time it goes back and forth. . The principle of Q-modulation is to use a device that can change the Q factor of the resonator to change the laser output optical power, which has been applied in Q-switched dye or solid-state lasers that generate periodic short pulses. Common prior art methods for implementing Q-switching include using rotating mirrors in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com