Process of preparing biological diesel

A biodiesel and bio-oil technology, which is applied in the preparation of biological raw materials, biofuels, and liquid hydrocarbon mixtures. It can solve the problems of low activity of heterogeneous catalysts, the need for repeated regeneration, and slow reaction speed, and achieve equipment investment and operation. Low cost, easy separation, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

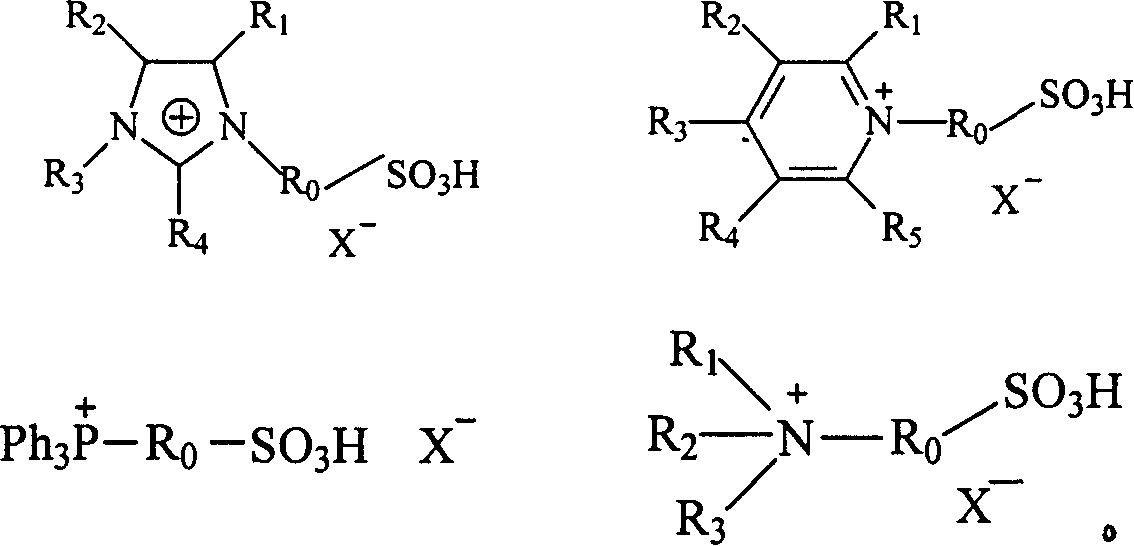

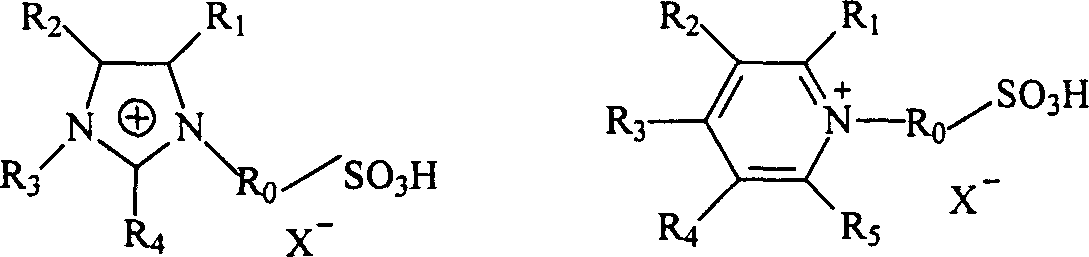

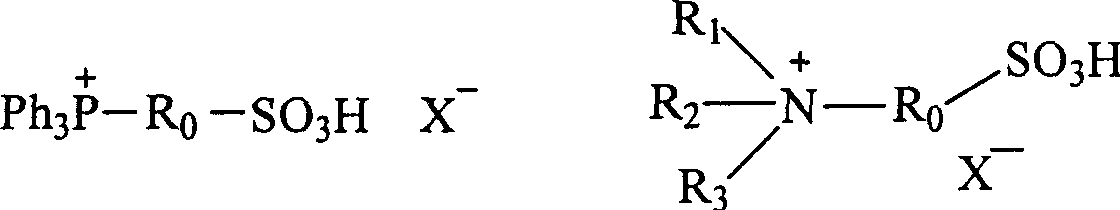

Method used

Image

Examples

Embodiment 1

[0027] Raw material and catalyst are added in the reactor by methanol: cottonseed oil: the mol ratio of pyridine butane sulfonic acid ionic liquid is 12: 1: 0.055, at reaction temperature be 170 ℃, under pressure 2.3MPa condition, stirring reaction 5 hours, Heating and stirring were stopped, the mixture was taken out, and left standing to be divided into two layers. The upper layer was a mixture of catalyst, methanol and glycerin, and the lower layer was a transesterification product. The yield of methyl ester was 92.5%.

Embodiment 2

[0029] The raw material and the catalyst are added in the reactor at a reaction temperature of 65° C. and a pressure of 0.1 MPa at a reaction temperature of 65° C. and a pressure of 0.1 MPa for 15 hours at a molar ratio of methanol: cottonseed oil: pyridine butane sulfonic acid ionic liquid. Heating and stirring were stopped, the mixture was taken out, and left standing to be divided into two layers. The upper layer was a mixture of catalyst, methanol and glycerin, and the lower layer was a transesterification product. The yield of methyl ester was 90.5%.

Embodiment 3

[0031] Raw material and catalyst are added in the reaction kettle by methanol: cottonseed oil: the mol ratio of pyridine butane sulfonic acid ionic liquid is 3: 1: 0.055, at reaction temperature be 170 ℃, under pressure 2.3MPa condition stirring reaction 20 hours, Heating and stirring were stopped, the mixture was taken out, and left standing to be divided into two layers. The lower layer was a mixture of catalyst, methanol and glycerin, and the upper layer was a transesterification product. The yield of methyl ester was about 91.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com